Copper-containing silicon material, method for manufacturing same, negative-electrode active substance, and secondary cell

A manufacturing method and technology of silicon materials, applied in the direction of secondary batteries, non-aqueous electrolyte batteries, lithium batteries, etc., can solve the problems of reduced cycle characteristics, easy condensation, high energy, etc., and achieve the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079]

[0080] Calcium metal, copper metal and silicon metal were weighed into a carbon crucible at an atomic ratio of Ca:Cu:Si=1.05:0.25:1.65, and heated to about 1300°C with a high-frequency induction heating device to melt it. The molten metal was poured into a predetermined mold for casting, and the obtained ingot was pulverized and classified with a sieve to a particle size passing through a sieve opening of 53 μm. The powder is CaCu x Si y Copper-containing calcium silicide represented by (x=0.25, y=1.65, x+y=1.9).

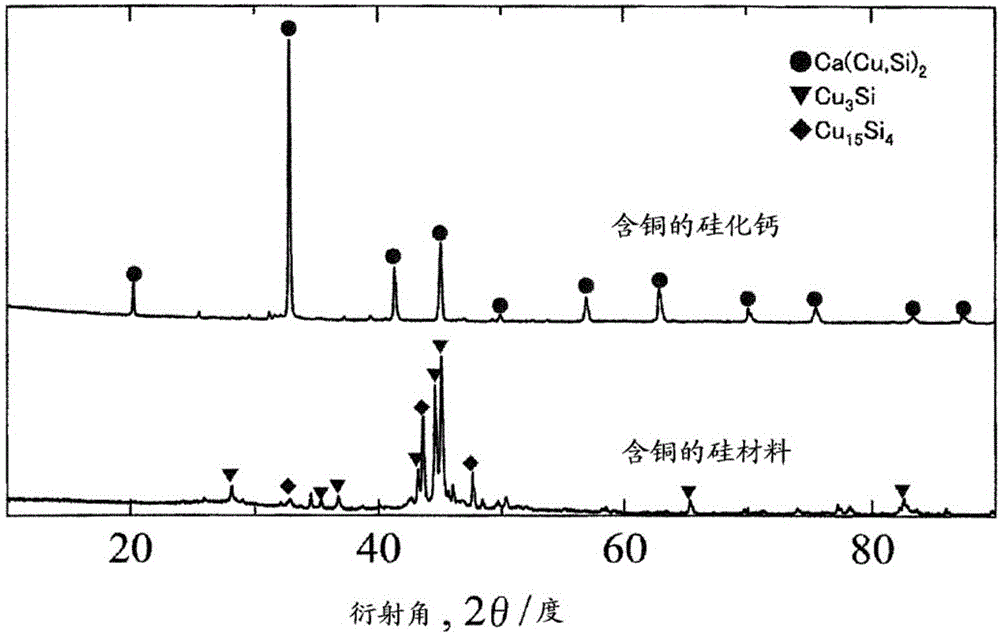

[0081] The XRD pattern of the copper-containing calcium silicide obtained is shown in figure 1 . As the X-ray source, Cu-Kα rays are used. Using the X-ray diffraction pattern (diffraction angle 2θ = range of 10 to 90°) obtained by the measurement, the analysis was performed with analysis software (software name: PDXL). figure 1 All the diffraction peaks shown in can be indexed to the structure of space group P6 / mmm of International Table Notation 191...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com