Sulfonic acid group functionalized siloxy alkene for zinc-based flow battery and preparation method of sulfonic acid group functionalized siloxy alkene

A sulfonic acid group, siloxane technology, applied in hydrogenated silicon, battery electrodes, regenerative fuel cells, etc., to promote uniform deposition performance, inhibit dendrite growth and accumulation problems, improve Coulomb efficiency and cycle stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Weigh 2g CaSi 2 As the silicide raw material powder, it was placed in a 500ml orange cap bottle.

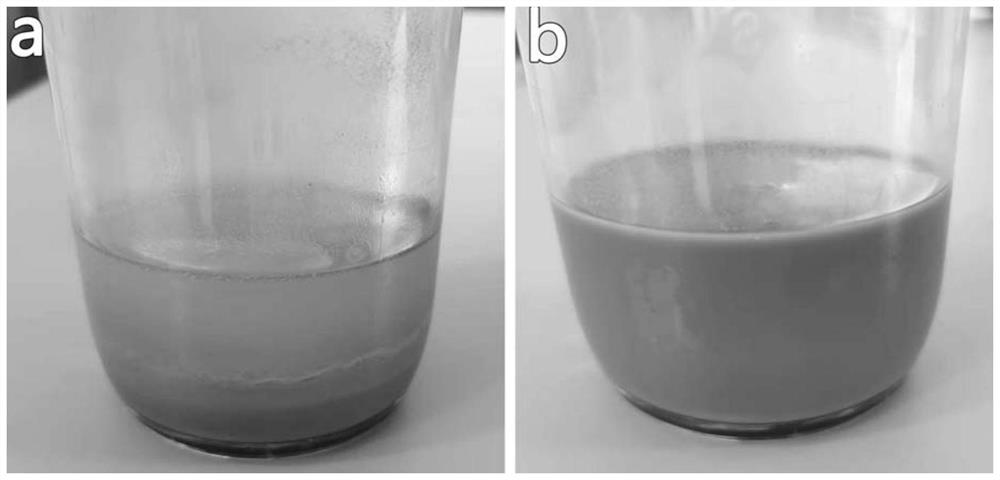

[0046] (2) Take 100ml of concentrated hydrochloric acid (mass fraction 36%-38%) and add it to the orange cap bottle in (1) to obtain a green turbid solution, and place the solution in a -10°C ethanol bath to pre-cool to -10°C.

[0047] (3) The turbid solution in (2) was pre-cooled to -10°C, and the sonicator was used to assist the reaction. The ultrasonic power was 300W, the reaction time was 48h, and the temperature of the reaction solution was maintained at -10°C.

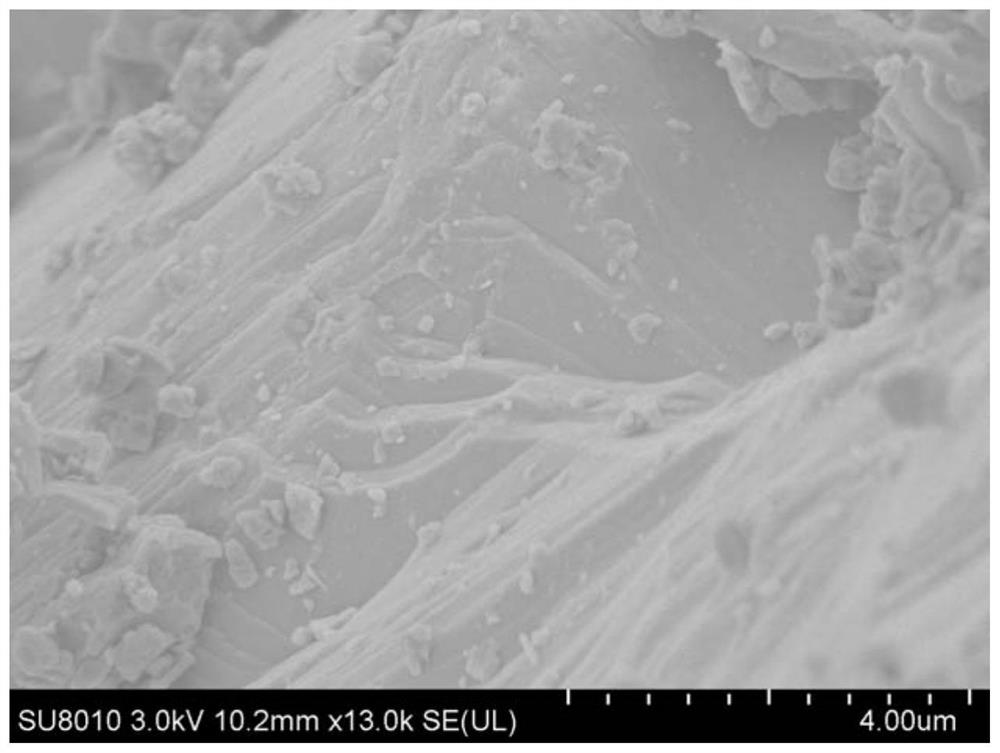

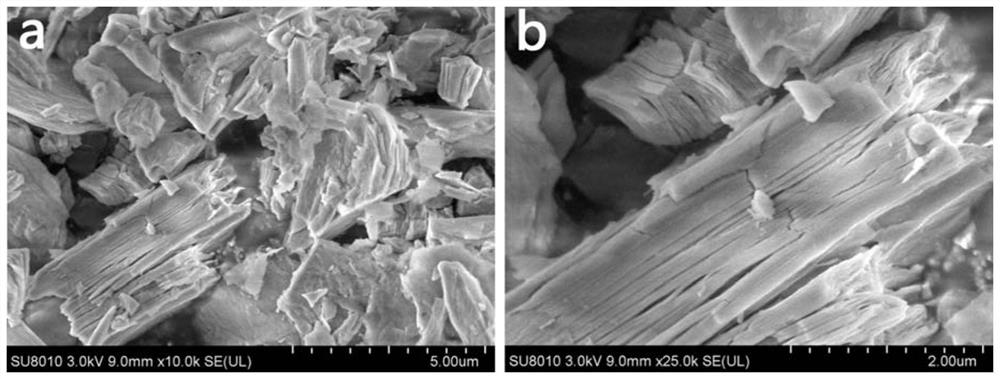

[0048] (4) Vacuum filtration of the turbid solution in (3) to collect gray wet powder to obtain siloxene nanosheets with good morphology.

[0049] (5) Pre-prepared concentration in absolute ethanol solvent is 0.5mol L -1 sulfanilic acid solution.

[0050] (6) Add the wet powder collected in (4) into 30 ml of the ethanolic solution of sulfonic acid amine prepared in (5), ultrasonically assisted dispersi...

Embodiment 2

[0060] Take the same steps as Example 1 to prepare sulfonic acid group-functionalized siloxane, except that 100 ml of concentrated hydrochloric acid in step (2) of Example 1 is replaced with 50 ml of phosphoric acid solution (85 wt.% in H 2 0), other reaction conditions were not changed.

[0061] The TEM characterization showed that the thickness of the siloxene nanosheets was significantly higher than that of the siloxyene nanosheets prepared in Example 1, which indicated that phosphoric acid was used as a topological solvent and oxidant to exfoliate CaSi. 2 The efficiency is lower than that of hydrochloric acid as the topochemical solvent and oxidant to exfoliate CaSi 2 , but it can also be seen from the TEM picture that phosphoric acid also successfully decomposes the layered dense structure of CaSi 2 The siloxene nanosheets exfoliated into independent sheet-like structures indicate that phosphoric acid is also a suitable topochemical solvent and oxidant.

Embodiment 3

[0063] Take the same steps as in Example 1 to prepare sulfonic acid group-functionalized siloxane, the difference is: 0.5mol L in step (5) of Example 1 -1 The sulfanilic acid solution was replaced with 0.5 mol L -1 of poly(4-styrenesulfonic acid) solution, and other reaction conditions were not changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com