Oxygen-containing silicon nanosheet supported noble metal catalyst as well as preparation method and application thereof

A technology of noble metal catalysts and silicon nanosheets, which is applied in the direction of electrochemical generators, fuel cells, electrical components, etc., can solve the problems of noble metal active site masking and difficulty in accurately controlling the content, so as to improve the utilization rate and electrocatalytic efficiency, The preparation process is simple and the effect of simplifying the preparation reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

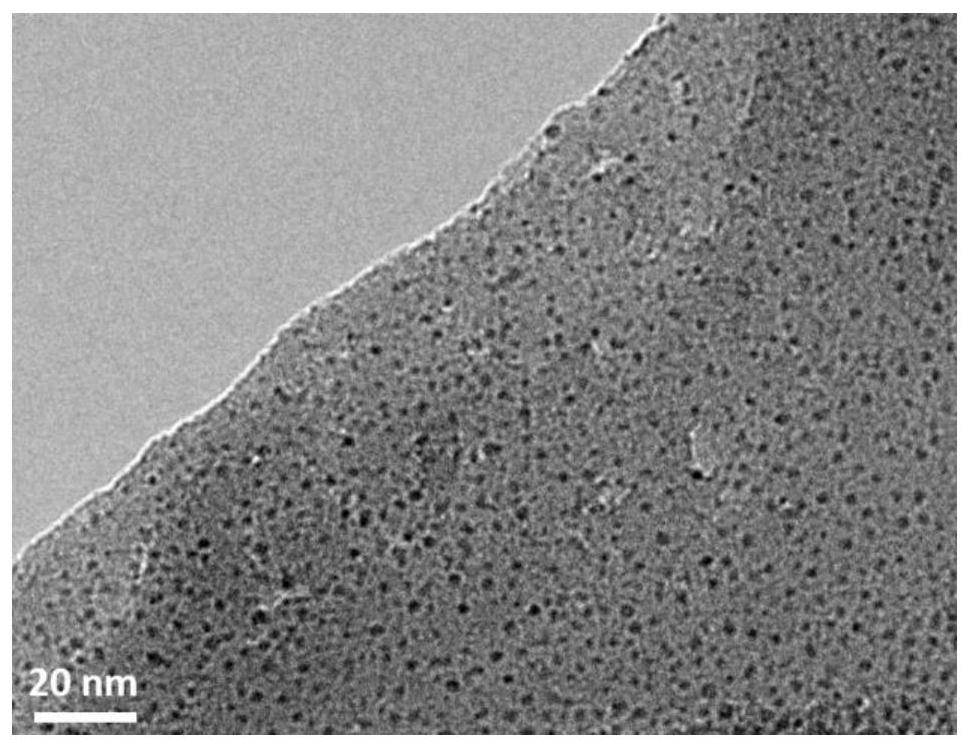

Image

Examples

Embodiment 1

[0032] A preparation method of oxygen-containing silicon nanosheet supported noble metal platinum catalyst, comprising the following steps:

[0033] (1) Preparation of oxygen-containing silicon nanosheets: under vigorous stirring and a constant temperature of 25°C, 2g of calcium silicide powder was added to 200mL of concentrated hydrochloric acid for etching reaction, and then the resulting precipitate was washed and purified with acetone and ultrapure water , then centrifuged, freeze-dried, and collected to obtain oxygen-containing silicon nanosheet powder.

[0034] (2) Dissolve chloroplatinic acid in 30 mL of ultrapure water to form a chloroplatinic acid solution with a concentration of 2.0 mmol / L. Subsequently, the solid product oxygen-containing silicon nanosheets prepared in step (1) was added to the solution, and a uniform dispersion (3.0 mg / mL) was formed by ultrasonic treatment. Then, the mixed solution was transferred to an autoclave, and reacted for 12 hours at a te...

Embodiment 2

[0036] A preparation method of oxygen-containing silicon nanosheet supported noble metal palladium catalyst, comprising the following steps:

[0037](1) Preparation of oxygen-containing silicon nanosheets: under vigorous stirring and ice bath conditions, 2 g of calcium silicide powder was added to 200 mL of concentrated hydrochloric acid for etching reaction, and then the obtained precipitate was washed and purified with acetone and ultrapure water, Further, centrifugal separation and freeze-drying are carried out to obtain oxygen-containing silicon nanosheet powder.

[0038] (2) Potassium chloropalladate was dissolved in 30 mL of ultrapure water to form a potassium chloropalladate solution with a concentration of 1.5 mmol / L. Subsequently, the solid product oxygen-containing silicon nanosheets prepared in step (1) was added to the solution, and a uniform dispersion (2.0 mg / mL) was formed by ultrasonic treatment. Then, the mixed solution was transferred to an autoclave, and re...

Embodiment 3

[0040] A preparation method of oxygen-containing silicon nanosheet supported noble metal iridium catalyst, comprising the following steps:

[0041] (1) Preparation of oxygen-containing silicon nanosheets: under vigorous stirring and ice bath conditions, 2 g of calcium silicide powder was added to 200 mL of concentrated hydrochloric acid for etching reaction, and then the obtained precipitate was washed and purified with acetone and ultrapure water, Further, centrifugal separation and freeze-drying are carried out to obtain oxygen-containing silicon nanosheet powder.

[0042] (2) Dissolve chloroiridic acid in 30 mL of ultrapure water to form a chloroiridic acid solution with a concentration of 1.2 mmol / L. Subsequently, the solid product oxygen-containing silicon nanosheets prepared in step (1) was added to the solution, and a uniform dispersion (2.0 mg / mL) was formed by ultrasonic treatment. Then, the mixed solution was transferred to an autoclave, and reacted for 12 hours at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com