Method for preparing two-dimensional layered silicon nanosheet material based on topological chemical method

A two-dimensional layered, topological chemistry technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve problems such as Si layer oxidation, and achieve increased specific surface area and productivity. High, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

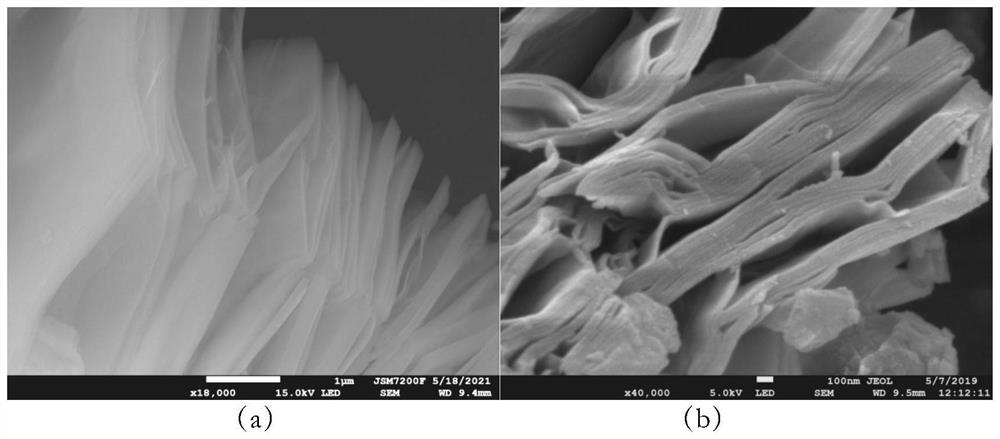

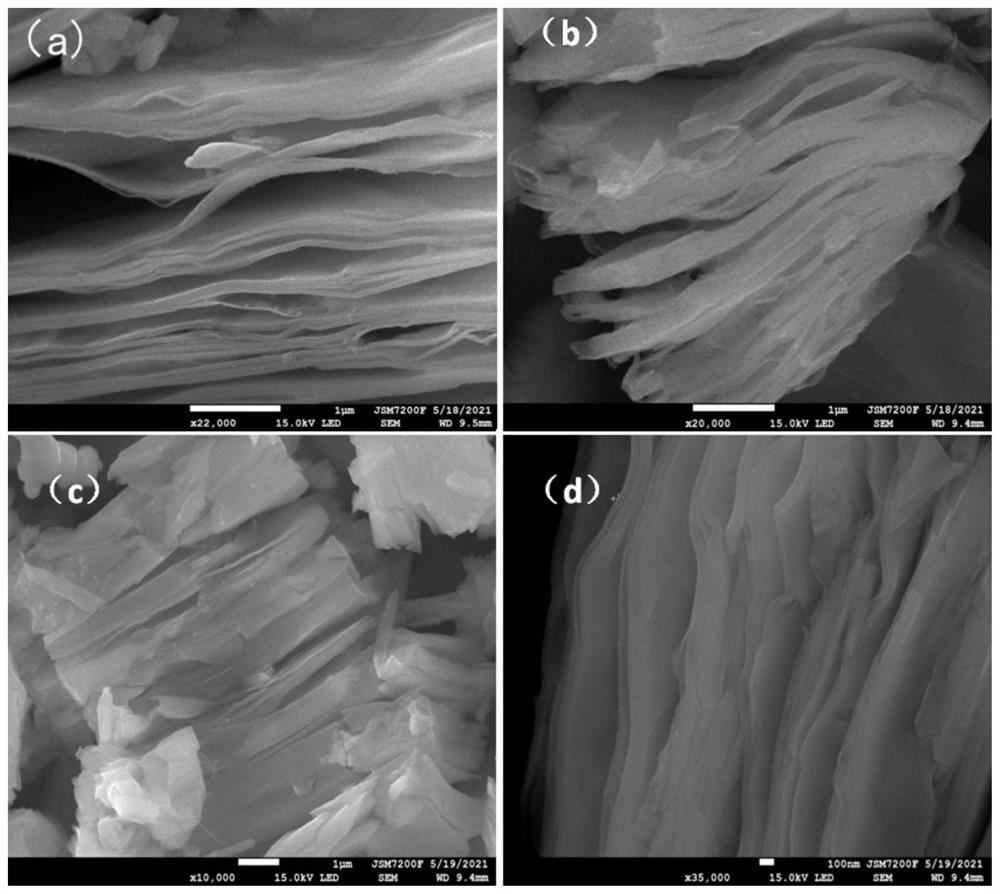

[0041] (1) Weigh 0.4g of sodium hydroxide and dissolve it in 50mL of deionized water to prepare a 2mol / L sodium hydroxide solution, weigh 1.2g of calcium silicide and dissolve it in 50mL of sodium hydroxide solution, fully stir it and let it stand After a while, suction filtration was performed and placed in a blast drying oven at 60°C for 1 hour to obtain purified calcium silicide;

[0042] (2) Weigh 0.8g of stannous chloride and dissolve it in 40mL of ethanol, add 0.2g of calcium silicide and 0.01g of sodium dodecyl sulfate (SDS), and fully stir to obtain a certain concentration of the reaction precursor;

[0043] (3) Put the prepared reaction precursor solution in a water bath at 60°C to react for 600 minutes. After the reaction is complete, a homogeneous solution with a certain concentration is obtained;

[0044] (4) Washing and centrifuging the homogeneous solution at a speed of 8000 rpm, using ethanol as a detergent for the first three times, and washing with a mixed sol...

Embodiment 2

[0046] (1) Weigh 0.4g of sodium hydroxide and dissolve it in 50mL of deionized water to prepare a 2mol / L sodium hydroxide solution, weigh 1.2g of calcium silicide and dissolve it in 50mL of sodium hydroxide solution, fully stir it and let it stand After a while, suction filtration was performed and placed in a blast drying oven at 60°C for 1 hour to obtain purified calcium silicide;

[0047] (2) Weigh 0.9g of stannous chloride and dissolve it in 60mL of ethanol, add 0.2g of calcium silicide and 0.05g of sodium dodecylbenzenesulfonate (SDBS), and stir well to obtain a certain concentration of the reaction precursor ;

[0048] (3) Put the prepared reaction precursor solution in a water bath at 60°C to react for 600 minutes. After the reaction is complete, a homogeneous solution with a certain concentration is obtained;

[0049] (4) Washing and centrifuging the homogeneous solution at a speed of 6000 rpm, using ethanol as a detergent for the first three times, and washing with a...

Embodiment 3

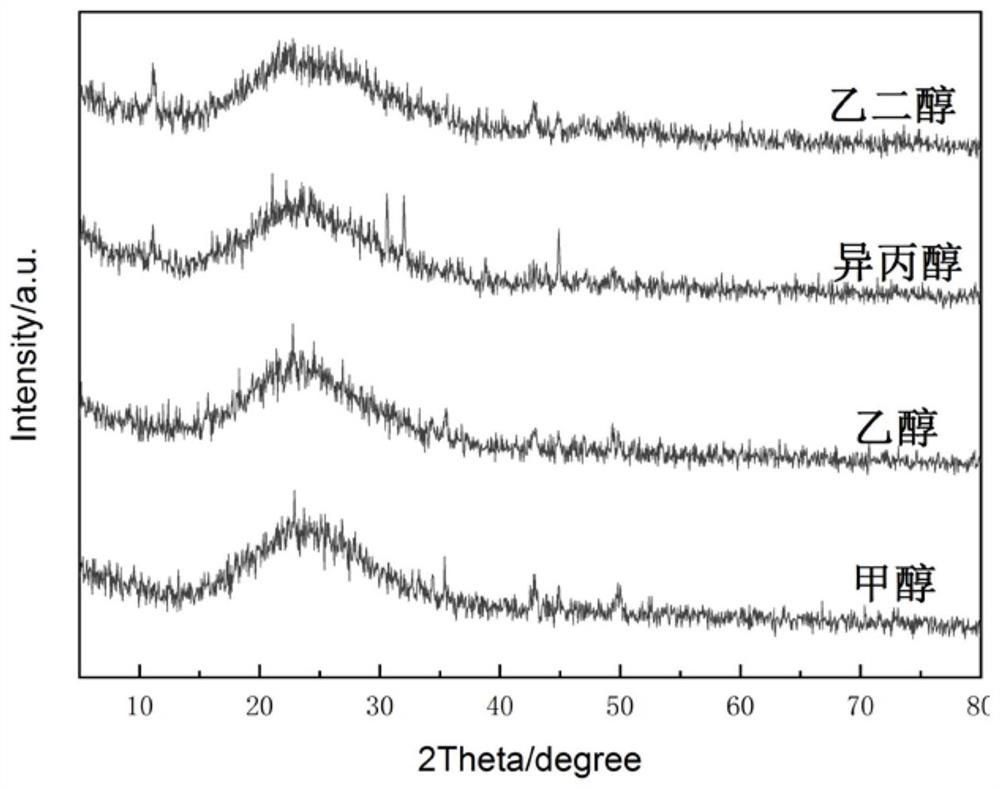

[0051] (1) Weigh 0.4g of sodium hydroxide and dissolve it in 50mL of deionized water to prepare a 2mol / L sodium hydroxide solution, weigh 1.2g of calcium silicide and dissolve it in 50mL of sodium hydroxide solution, fully stir it and let it stand After a while, suction filtration was performed and placed in a blast drying oven at 60°C for 1 hour to obtain purified calcium silicide;

[0052] (2) Weigh 1.14g of stannous chloride and dissolve it in 70mL of methanol, add 0.2g of calcium silicide and 0.1g of dispersant SDS to it, and fully stir to obtain a certain concentration of the reaction precursor;

[0053] (3) Put the prepared reaction precursor solution in a water bath at 60°C to react for 600 minutes. After the reaction is complete, a homogeneous solution with a certain concentration is obtained;

[0054] (4) Wash and centrifuge the homogeneous solution at a speed of 8000 rpm, use methanol as a detergent for the first three times, and use a mixed solution of 3% hydrochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com