Organic Compounds and Their Applications, Organic Light Emitting Diode Electroluminescent Devices

A technology for electroluminescent devices and organic compounds, which is applied in the fields of silicon organic compounds, organic chemistry, electric solid devices, etc., can solve the problems of increasing the driving voltage of OLED devices, and achieve long service life, high hole transport rate, and high external quantum. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

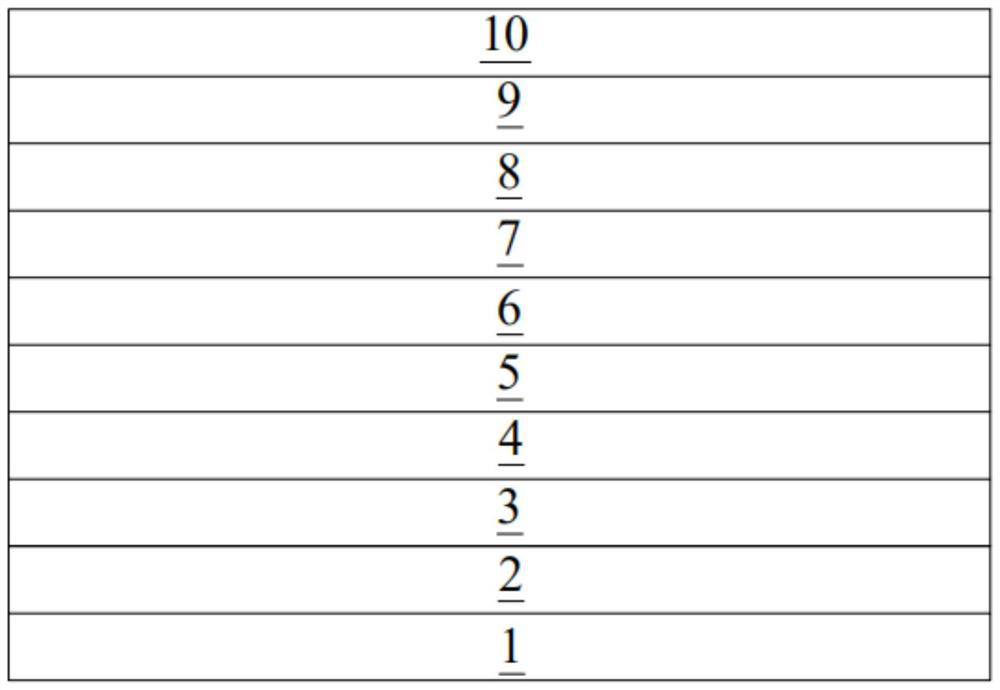

Image

Examples

Embodiment 1

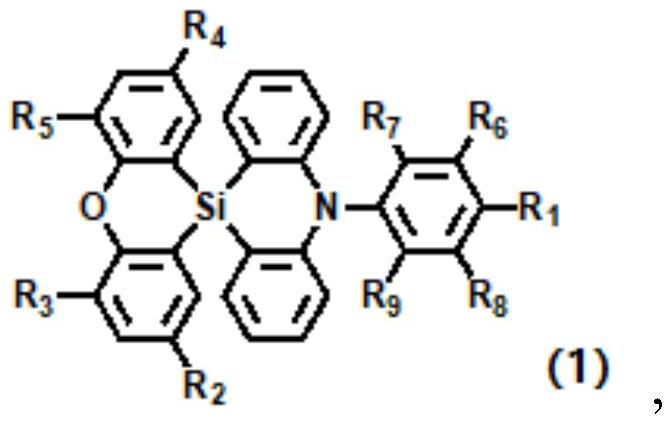

[0027] The synthetic route of the organic compound 1 is as follows:

[0028]

[0029] The organic compound 1 synthesis steps are as follows:

[0030] (1) Add raw material 1 (3.42 g, 5 mmol), carbazole (1.00 g, 6 mmol), palladium (45 mg, 0.2 mmol) and tri-tert-butylphosphine tetrafluororate (0.17 g). 0.6 mmol), then Naot-Bu (0.58 g, 6 mmol) was added to the glove box, and 100 mL of the oxygen-removal oxygen was added to the lid of the oxygen in the branch, and at 120 ° C for 24 hours.

[0031] (2) The reaction liquid is cooled to room temperature, pour the reaction solution into 200 ml of ice water, extract three times, combined with dichloromethane, combined with organic phase, cephally silica gel, column chromatography (dichloromethane: n-hexane, v: V, 1) : 5) Separate purification, with a white powder 2.3 g, and the yield is 60%.

Embodiment 2

[0033] The synthetic route of the organic compound 2 is as follows:

[0034]

[0035] The synthesis step of the organic compound 2 is as follows:

[0036] (1) Add raw materials 1 (3.42 g, 5 mmol), diphenylamine (1.01 g, 6 mmol), palladium acetate (45 mg, 0.2 mmol) and tri-tert-butylphosphine tetrafluororate (0.17 g). 0.6 mmol), then Naot-Bu (0.58 g, 6 mmol) was added to the glove box, and 100 mL was added to the argon atmosphere to remove hydraulic toluene in advance, reacted at 120 ° C for 24 hours.

[0037] (2) The reaction liquid was cooled to room temperature, poured into 200 ml of ice water, and dichloromethane was extracted three times, combined with organic phases, camped into silica gel, column chromatography (dichloromethane: n-hexane, V: V, 1: 5) Separate purification, with a white powder 2.5 g, and the yield is 65%.

Embodiment 3

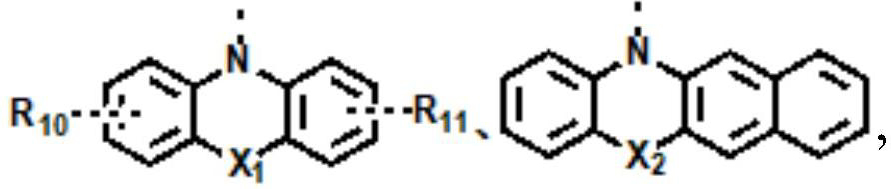

[0039] The synthetic route of the organic compound 3 is as follows:

[0040]

[0041] The synthesis step of the organic compound 3 is as follows:

[0042] (1) Add raw material 1 (3.42 g, 5 mmol), 9,9'-dimethyl acridine (1.26 g, 6 mmol), palladium acetate (45 mg, 0.2 mmol) and tri-butylphosphine Tetrafluoroborate (0.17 g, 0.6 mmol), then Naot-bu (0.58 g, 6 mmol) was added to the glove box, and 100 mL of the pre-water removal of oxygen toluene was reacted at 120 ° C under the carbon atmosphere. Hour.

[0043] (2) The reaction liquid is cooled to room temperature, pour the reaction liquid into 200 ml of ice water, extracted three times with dichloromethane, combined with organic phase, cepnthromic silica gel, column chromatography (dichloromethane: n-hexane, V: V, 1) : 5) Separate purification, with a white powder 2.6 g, yield of 64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com