Modified PVC material for wires and preparation method of modified PVC material

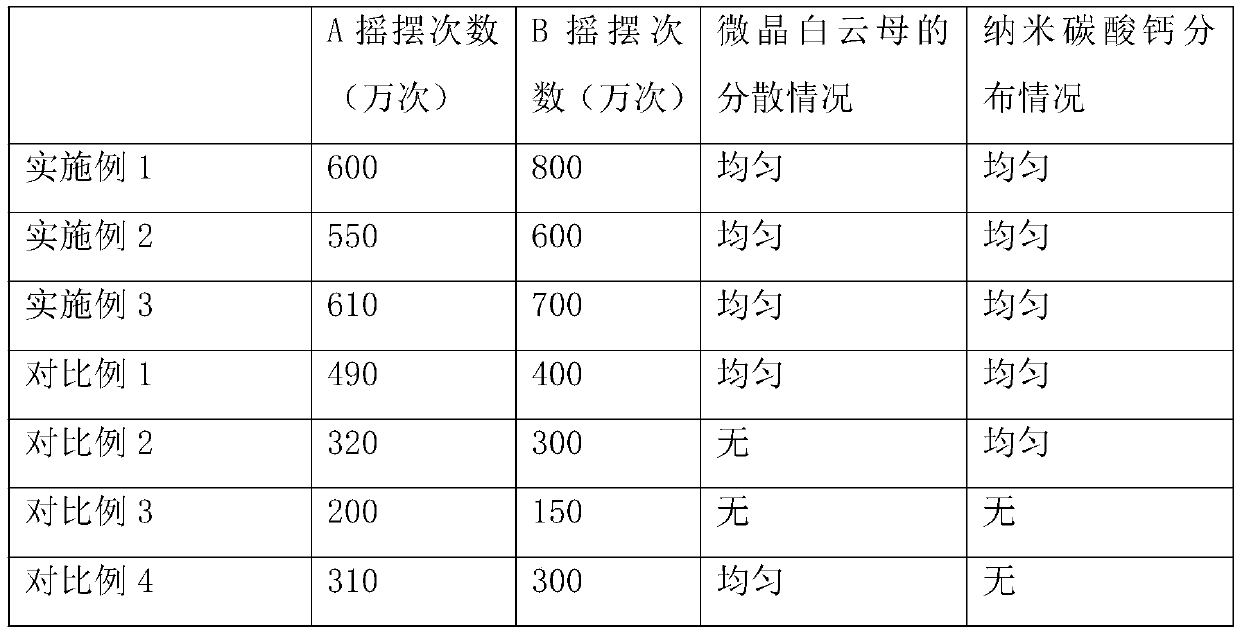

A PVC material and modified technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of unstable anti-swing performance, poor dispersion of nano-calcium carbonate, general dispersion, etc., to achieve fatigue resistance Increase, improve mechanical properties, ensure the effect of dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] S1: Take 50 parts of nano silicon dioxide and mix it with deionized water, add 2 parts of polymerizable carbon-carbon double bond coupling agent at the same time, heat and stir for 30min, the temperature is 70-80°C;

[0025] S2: Get 50 parts of nano-calcium carbonate, add 10 parts of mixed solvent methyl methacrylate, 15 parts of emulsifier, 10 parts of ethyl acrylate, stir so that the outer wrapping mixed solvent particle of nano-calcium carbonate;

[0026] S3: Take 300 parts of PVC matrix and 100 parts of ABS rubber for polymerization reaction, and evenly disperse the mixture of the two in water with a dispersant. During the reaction, add the modified nano-silica prepared in S1 to obtain a modified polymer Vinyl product A;

[0027] S4: Take 30 parts of microcrystalline muscovite powder, after desorbing water, add a coupling agent, and mix with a high-speed mixer to prepare modified muscovite powder;

[0028] S5: Take the modified polyethylene product A prepared in S3...

Embodiment 2

[0030] The invention proposes a modified PVC material for electric wires, including 300-800 parts of PVC matrix, 100-200 parts of ABS rubber, 50-100 parts of nano-silica, 50-100 parts of nano-calcium carbonate, and 30 parts of microcrystalline muscovite -50 parts, 2-10 parts of plasticizer, 2-10 parts of stabilizer, 2-10 parts of lubricant, 2-10 parts of polymerizable carbon-carbon double bond coupling agent.

[0031] S1: Take 80 parts of nano silicon dioxide and mix it with deionized water, add 2 parts of polymerizable carbon-carbon double bond coupling agent at the same time, heat and stir for 30min, the temperature is 70-80°C;

[0032] S2: Get 80 parts of nano-calcium carbonate, add 1 part of mixed solvent methyl methacrylate, 15 parts of emulsifier, 10 parts of ethyl acrylate, stir so that the nano-calcium carbonate is wrapped with mixed solvent particles;

[0033] S3: Take 500 parts of PVC matrix and 150 parts of ABS rubber for polymerization reaction, and evenly disperse...

Embodiment 3

[0037] S1: Take 50 parts of nano-silica and mix it with deionized water, add 7 parts of a polymerizable carbon-carbon double bond coupling agent at the same time, heat and stir for 30 minutes, and the temperature is 70-80 ° C;

[0038] S2: Get 100 parts of nano-calcium carbonate, add 10 parts of mixed solvent methyl methacrylate, 15 parts of emulsifier, 10 parts of ethyl acrylate, stir so that the outer wrapping mixed solvent particle of nano-calcium carbonate;

[0039] S3: Take 800 parts of PVC matrix and 200 parts of ABS rubber for polymerization reaction, and evenly disperse the mixture of the two in water with a dispersant. During the reaction, add the modified nano-silica prepared in S1 to obtain a modified polymer Vinyl product A;

[0040] S4: Take 50 parts of microcrystalline muscovite powder, after desorbing water, add a coupling agent, and mix with a high-speed mixer to prepare modified muscovite powder;

[0041] S5: Take the modified polyethylene product A prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com