Cogeneration system for biomass gasifier

A technology of combined cooling and power generation and gasification furnace, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc. It can solve the problems of low utilization rate of industrial waste heat energy, affect engine performance, and high operating pressure, so as to improve system reliability performance, stable energy supply, improved combustion and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

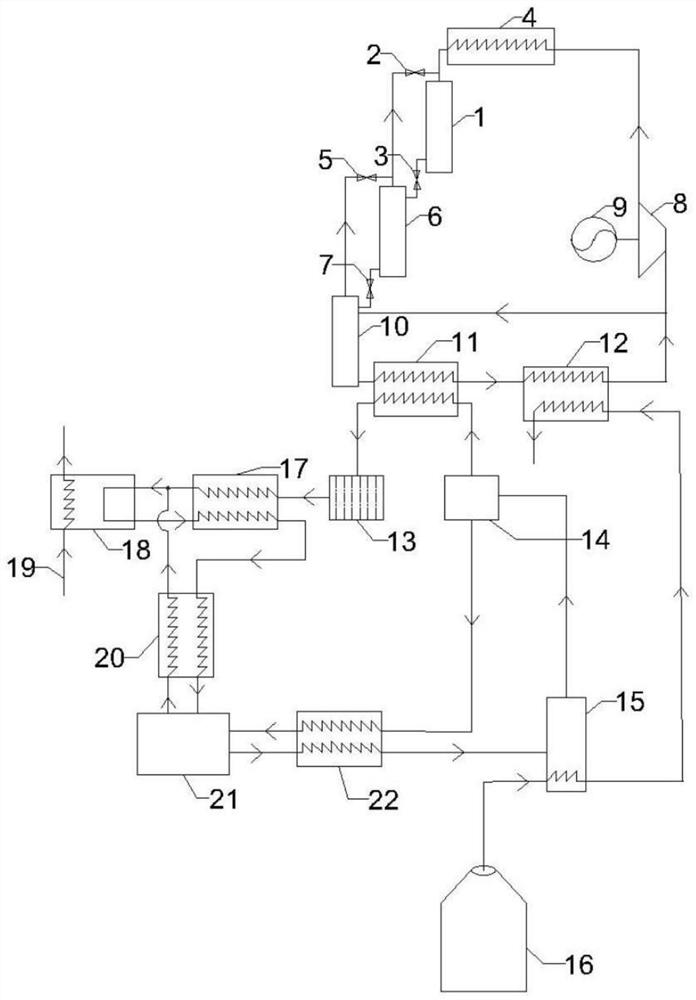

[0034]A biomass gasifier combined cooling and power system, such asfigure 1 As shown, it includes an absorption solution circulation loop, a liquid ammonia pipeline, an ammonia-helium mixture circulation loop and a pump-less organic Rankine cycle power generation mechanism. The system includes a liquid storage tank I1, a solenoid valve I2, a solenoid valve II3, a condenser I4, Solenoid valve III5, liquid storage tank II6, solenoid valve IV7, expander 8, generator 9, liquid storage tank10. Rectifier 11. Evaporator12. Condenser13. Gas-liquid separator 14, generator 15, biomass gasifier 16, liquid ammonia heat exchanger 17, evaporator18. Cold output 19, gas heat exchanger 20, absorber 21, solution heat exchanger 22; absorption solution circulation loop includes generator 15, gas-liquid separator 14, solution heat exchanger 22, liquid ammonia pipeline includes condensation Device13. Liquid ammonia heat exchanger 17, ammonia-helium mixed gas circulation loop including evaporator18. Absor...

Embodiment 2

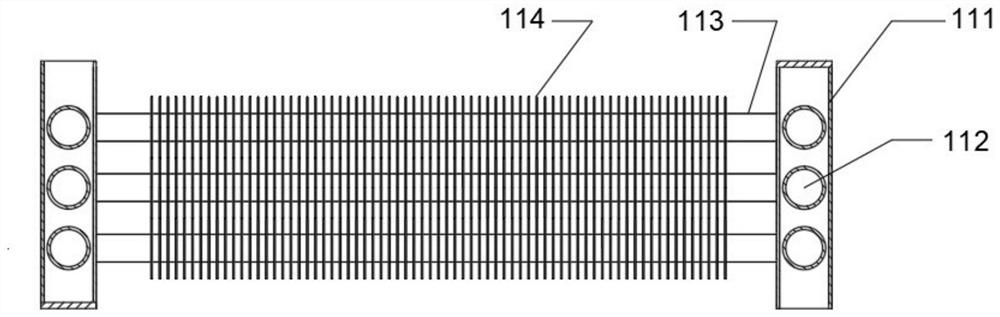

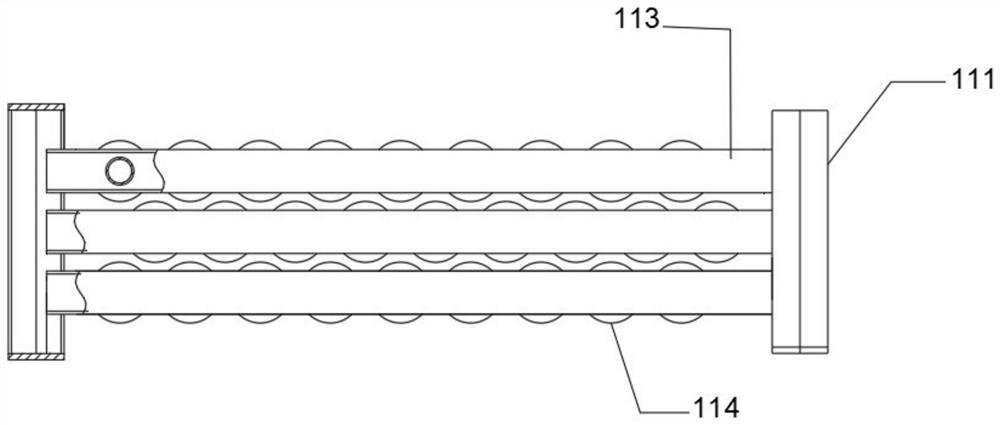

[0040]As the second embodiment of the present invention, such asfigure 2 ,image 3 withFigure 4As shown, the rectifier 11 includes two symmetrically arranged support frames 111, and a number of evenly and equidistantly arranged vent holes 112 are opened on one side of the two support frames 111, and a number of vent holes 112 are arranged between the two support frames 111. The water pipes 113 arranged evenly and equidistantly are connected with a number of evaporation fins 114 to improve the evaporation efficiency.

[0041]The specific working steps of the biomass gasifier cogeneration system of the present invention are as follows:

[0042](1) The biomass gasification furnace 16 supplies heat to the generator 15 so that the bubble pump in the generator 15 pushes the ammonia bubbles up and flows into the gas-liquid separator 14, and the liquid flows downward into the solution under the separation action of the gas-liquid separator 14 In the heat exchanger 22, the gas flows upward into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com