Molecular dynamics construction method for microcrack propagation in monocrystalline and polycrystalline titanium

A molecular dynamics and construction method technology, applied in the field of molecular dynamics construction, can solve the problems of component stiffness, strength, toughness and service life discount, and achieve the effect of less energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

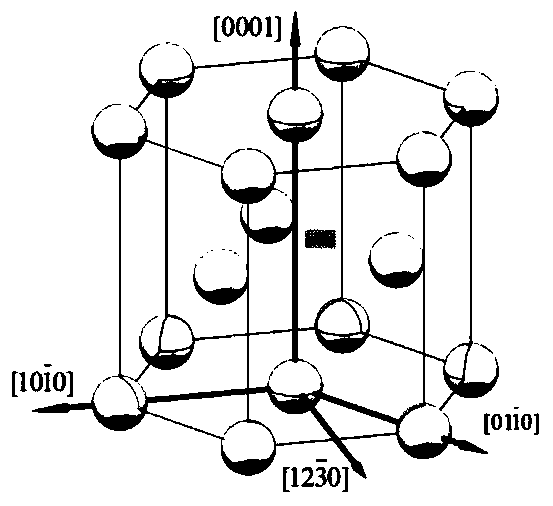

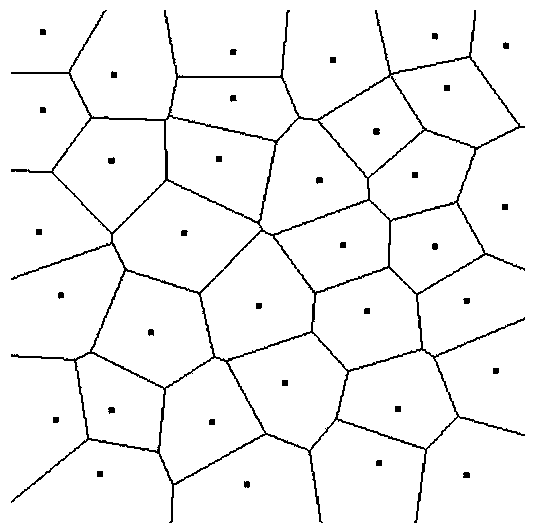

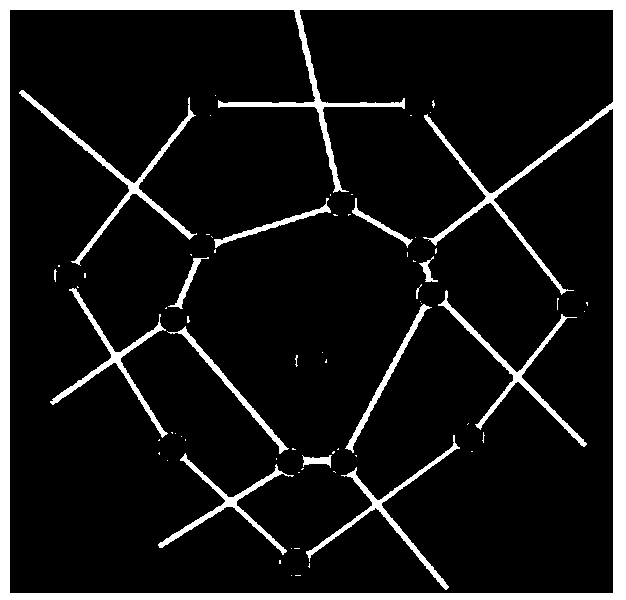

[0023] (1) Establishment of molecular dynamics simulation model: a single crystal titanium model with preset microcracks was established, and the crystal orientations were [1 0 -1 0], [0 0 0 1] and [1 2 -3 0] It is the three coordinate axis directions of x, y and z. The model size is 50 × 30 × 4 lattice units, with a total of 28865 atoms. By excluding atoms in the specified area, a slender microcrack of 8×0.2×0.2 lattice units is preset in the center of the model. To establish a polycrystalline titanium model, first establish an initial single crystal system, with the crystal directions [10-10], [1-210] and [0001] as the three coordinate axes directions of x, y and z, and the z axis is the crystal grid c-axis. According to the Voronoi algorithm, the established single crystal titanium model is divided into multiple grain regions. Randomly distribute n seeds in the single crystal titanium model, where n is the number of unit cells, and then divide n spaces with the seeds as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com