Modification method of electron transport layer for organic solar cell

An electron transport layer, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex solar cell preparation process, inability to influence the internal defects of the electron transport layer, etc. Achieve in-situ defect passivation and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

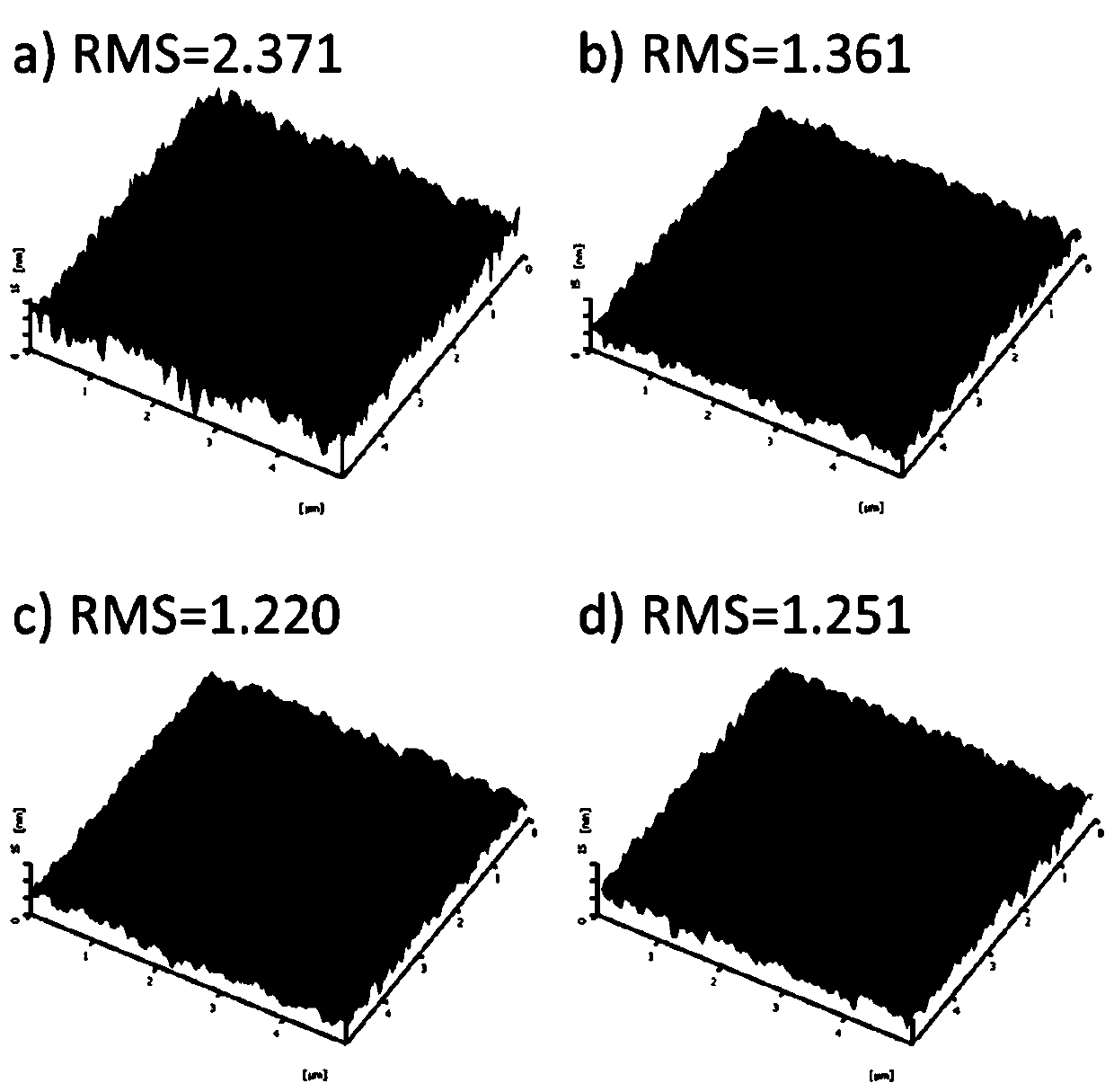

[0035] Weigh 1g of zinc acetate dihydrate, 0.28g of ethanolamine into a glass sample bottle, add 9.95mL of 2-methoxyethanol and 0.05mL of 4-tert-butylpyridine, put in a magnet, stir vigorously at room temperature for 12h, until the mixture is uniform , to prepare a modified zinc oxide precursor solution.

[0036] The above-mentioned modified zinc oxide precursor solution was spin-coated on ITO conductive glass at a speed of 4000rpm for 60s to form a thin film, and annealed at 200°C for 1h to obtain a planar modified zinc oxide electron transport layer, which was marked as TBP-ZnO(7.4 :100).

Embodiment 2

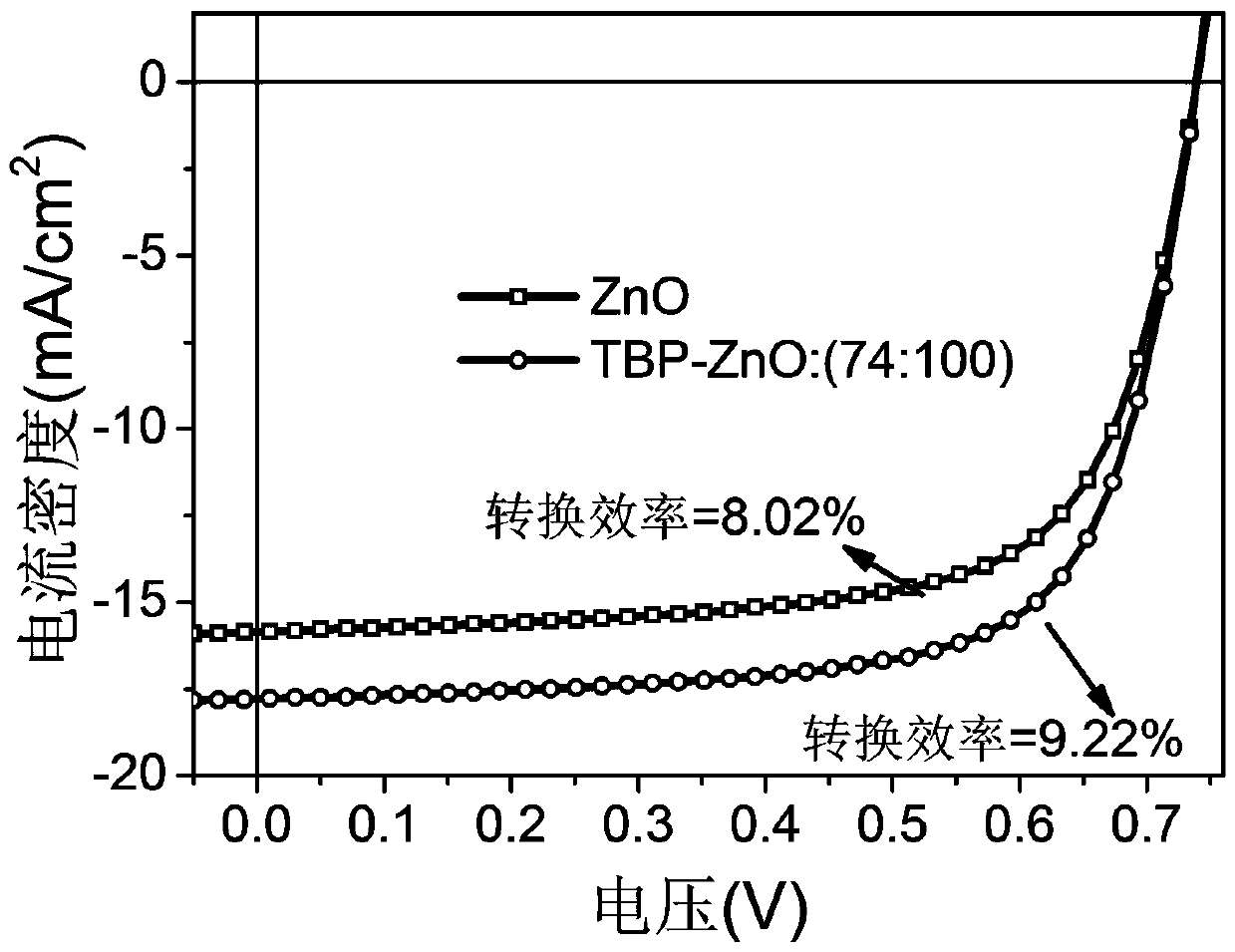

[0038] Weigh 1g of zinc acetate dihydrate and 0.28g of ethanolamine into a glass sample bottle, add 9.5mL of 2-methoxyethanol and 0.5mL of 4-tert-butylpyridine, put in a magnet, stir vigorously at room temperature for 12h, until the mixture is uniform , to prepare a modified zinc oxide precursor solution.

[0039] The above-mentioned modified zinc oxide precursor solution was spin-coated on ITO conductive glass at a speed of 4000rpm for 60s to form a thin film, and annealed at 160°C for 0.5h to obtain a planar modified zinc oxide electron transport layer, which was marked as TBP-ZnO ( 74:100).

Embodiment 3

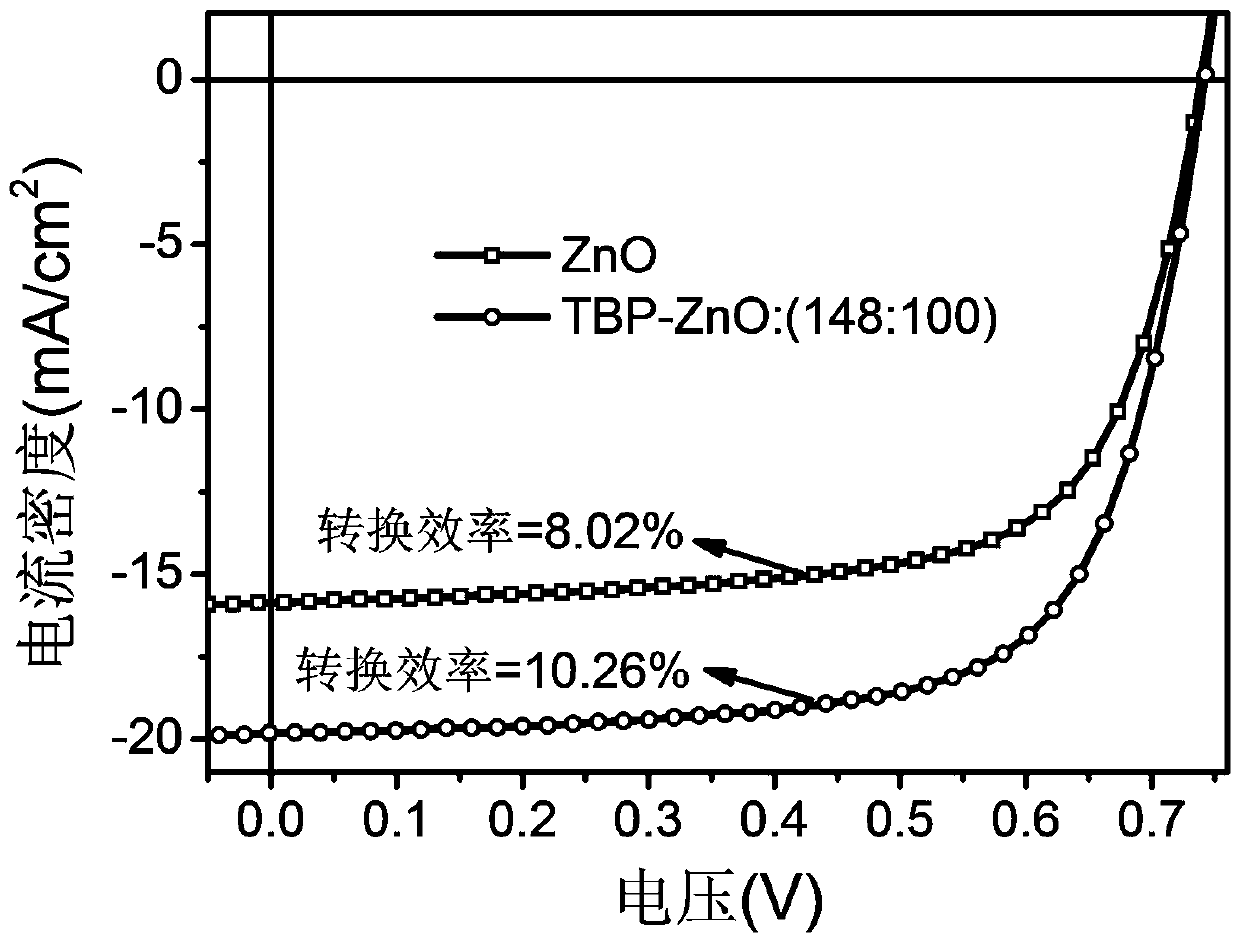

[0041] Weigh 1g of zinc acetate dihydrate and 0.28g of ethanolamine into a glass sample bottle, add 9mL of 2-methoxyethanol and 1mL of 4-tert-butylpyridine, put in a magnet, stir vigorously at room temperature for 12h, until the mixture is uniform, and prepare A modified zinc oxide precursor solution is obtained.

[0042] The above-mentioned modified zinc oxide precursor solution was spin-coated on ITO conductive glass at a speed of 4000rpm for 60s to form a thin film, and annealed at 230°C for 1h to obtain a planar modified zinc oxide electron transport layer, which was marked as TBP-ZnO(148 :100).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com