Heat dissipation structure for display panel and preparation method and application of heat dissipation structure

A heat dissipation structure and display panel technology, which is applied in the construction of electrical equipment components, modification through conduction heat transfer, cooling/ventilation/heating transformation, etc., can solve the problems of thick panels and poor heat dissipation effects of display panels, and achieve improved Heat dissipation effect, thickness reduction, and overall thickness reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

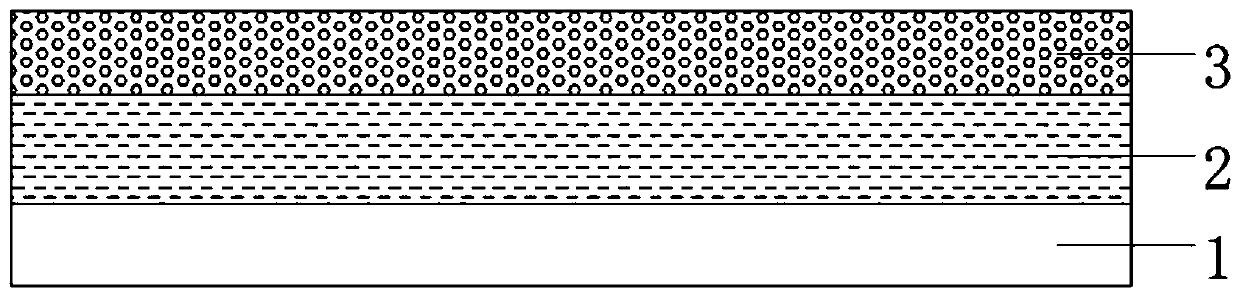

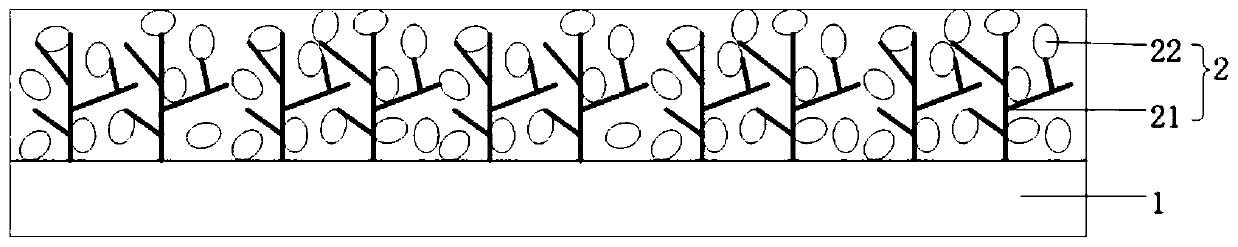

[0031] This embodiment provides a heat dissipation structure for a display panel, please refer to figure 2 , figure 2 Shown is a structural schematic diagram of the heat dissipation structure provided in this embodiment. The heat dissipation structure includes a copper foil layer 1 and a heat conduction layer 2 arranged on the copper foil layer 1, and the thickness of the heat conduction layer ranges from 50 μm to 150 μm.

[0032] The material used for the heat conduction layer 2 includes a heat conduction material 21 with a three-dimensional structure. In this embodiment, the three-dimensional structure of the heat conduction material 21 is a tree-like three-dimensional structure, and the material used is porous carbon. In other embodiments, the thermally conductive material 21 may also use carbon fiber network, which is not limited here.

[0033] The heat conduction material 21 with a tree-like three-dimensional structure establishes more heat diffusion channels, and the...

Embodiment 2

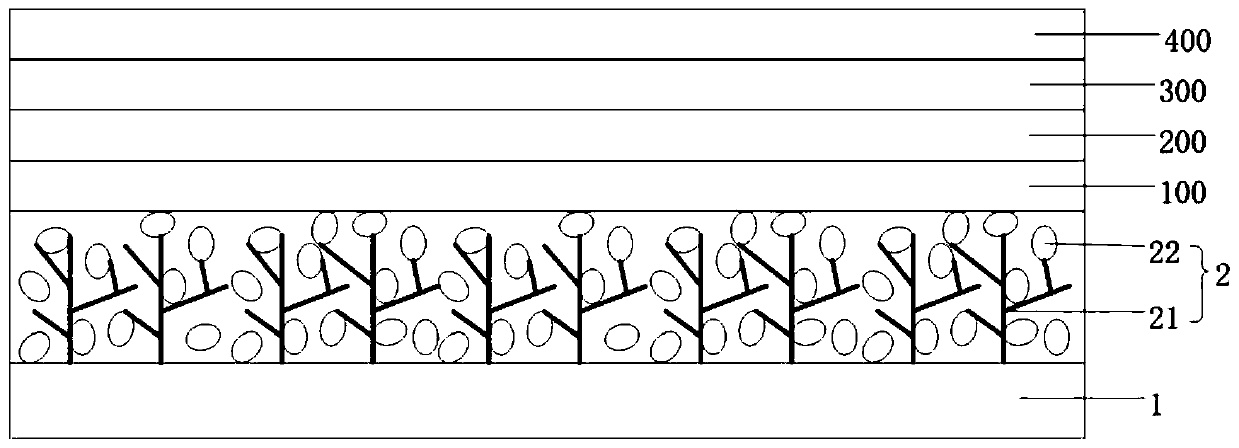

[0044] This embodiment provides a heat dissipation structure for a display panel, please refer to Figure 4 , Figure 4 Shown is a structural schematic diagram of the heat dissipation structure provided in this embodiment. The heat dissipation structure includes a copper foil layer 1 and a heat conduction layer 2 arranged on the copper foil layer 1, and the thickness of the heat conduction layer ranges from 50 μm to 150 μm.

[0045] The heat conduction layer 2 includes a one-dimensional heat conduction layer 21 and a two-dimensional heat conduction layer 22. The one-dimensional heat conduction layer 21 and the two-dimensional heat conduction layer 22 hybridize and grow to form a vertical three-dimensional structure. The heat conduction material used in the one-dimensional heat conduction layer 21 is a longitudinal nanotube. The heat conduction material used in the two-dimensional heat conduction layer 22 is a longitudinal nano-wall.

[0046] In other embodiments, the thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com