A fully automatic biomass stick incense production line

A biomass and fully automatic technology, applied in chemical/physical processes, lighting and heating equipment, manufacturing tools, etc., can solve the problems of high labor efficiency and low labor intensity, and achieve high labor efficiency, low labor intensity and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the technical solution of the present invention, the present invention will be described in detail below with reference to the accompanying drawings, and the description of this section is merely exemplary and interpretative, and no limitation should be made to the scope of the invention. .

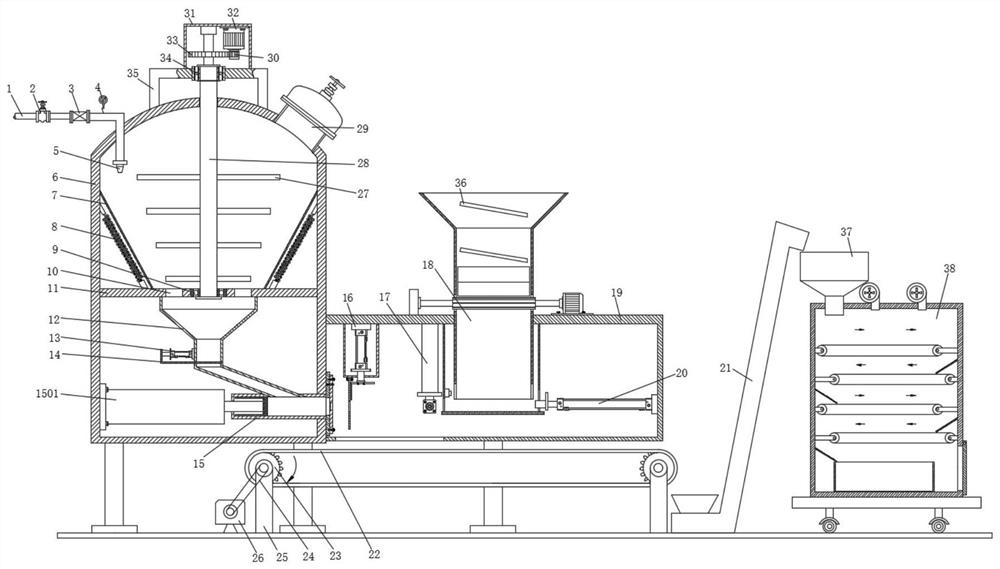

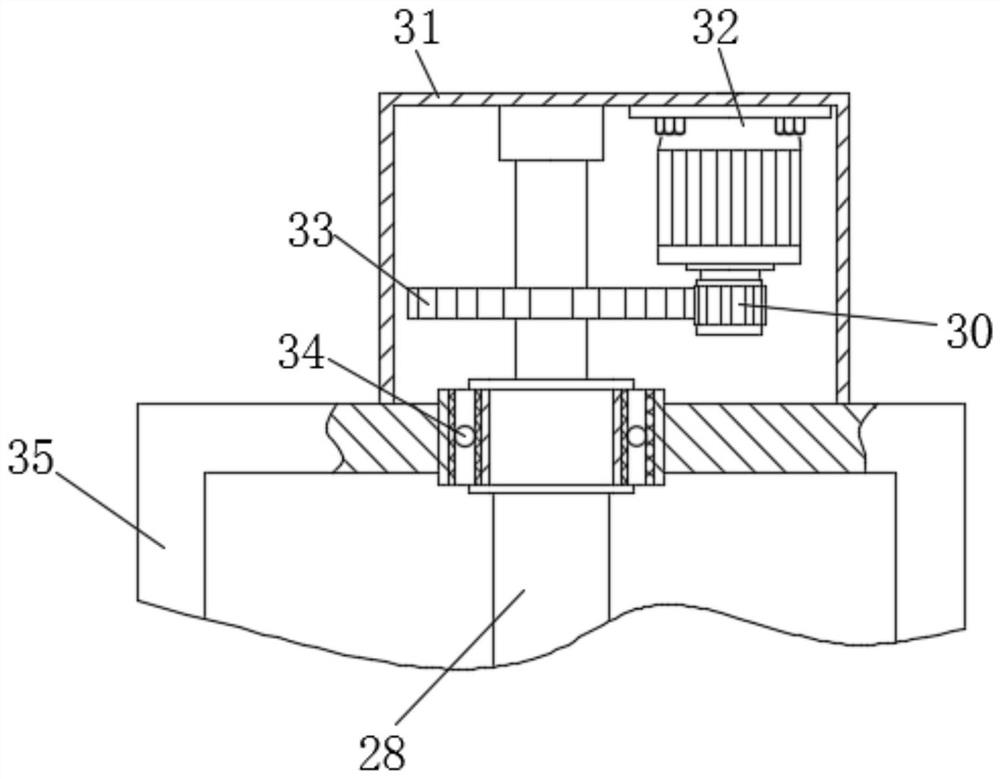

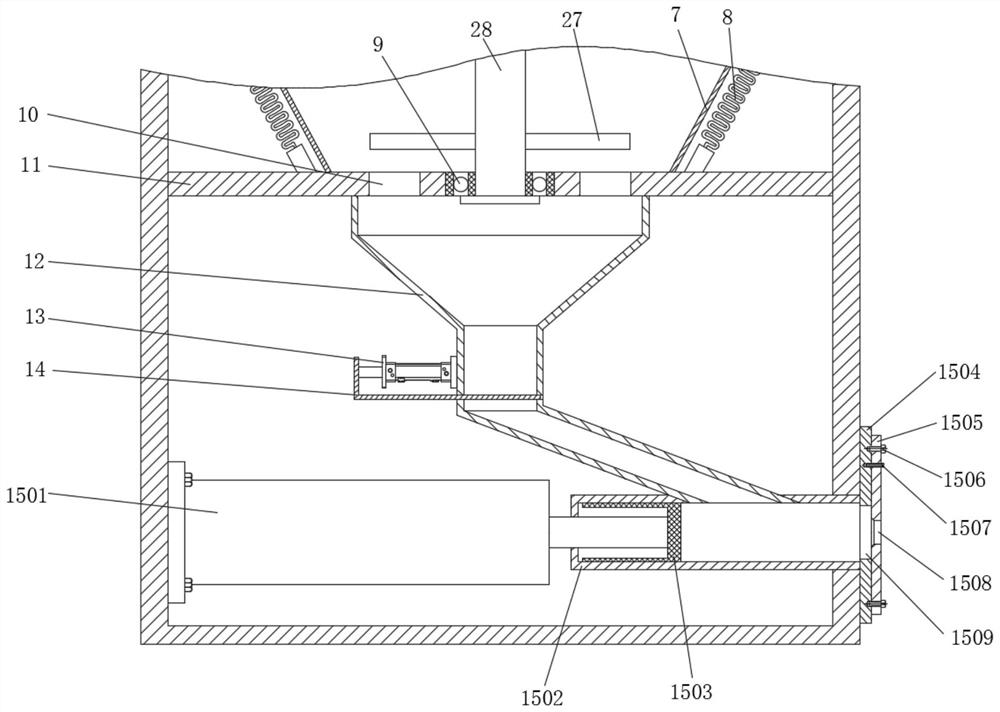

[0032] Such as Figure 1 - Figure 9 As shown, the specific structure of the present invention is: a fully automatic biomass rutal production line including the first housing 6 and the second housing 19, the top of the first housing 6 is provided with an injection port 29, the fixing frame 35 And the water pipe 1, the water pipe 1 is sequentially provided with the control valve 2, the flow sensor 3, and the temperature sensor 4, which can be monitored to the flow rate and temperature of the addition of water, and the top of the fastener 35 is provided with a third housing 31, the third The inner wall of the housing 31 is provided by a screw connection, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com