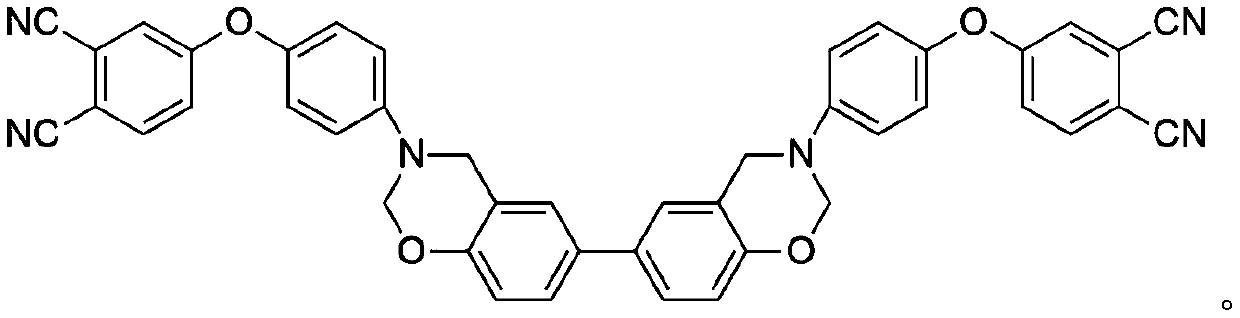

Resin polymer with high modulus and high glass transition temperature and preparation method thereof

A technology with high glass transition and transition temperature, applied in the field of resin-based composite materials, can solve the problems of high polymer brittleness, low glass transition temperature, limitations, etc., and achieve the effect of simple process and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

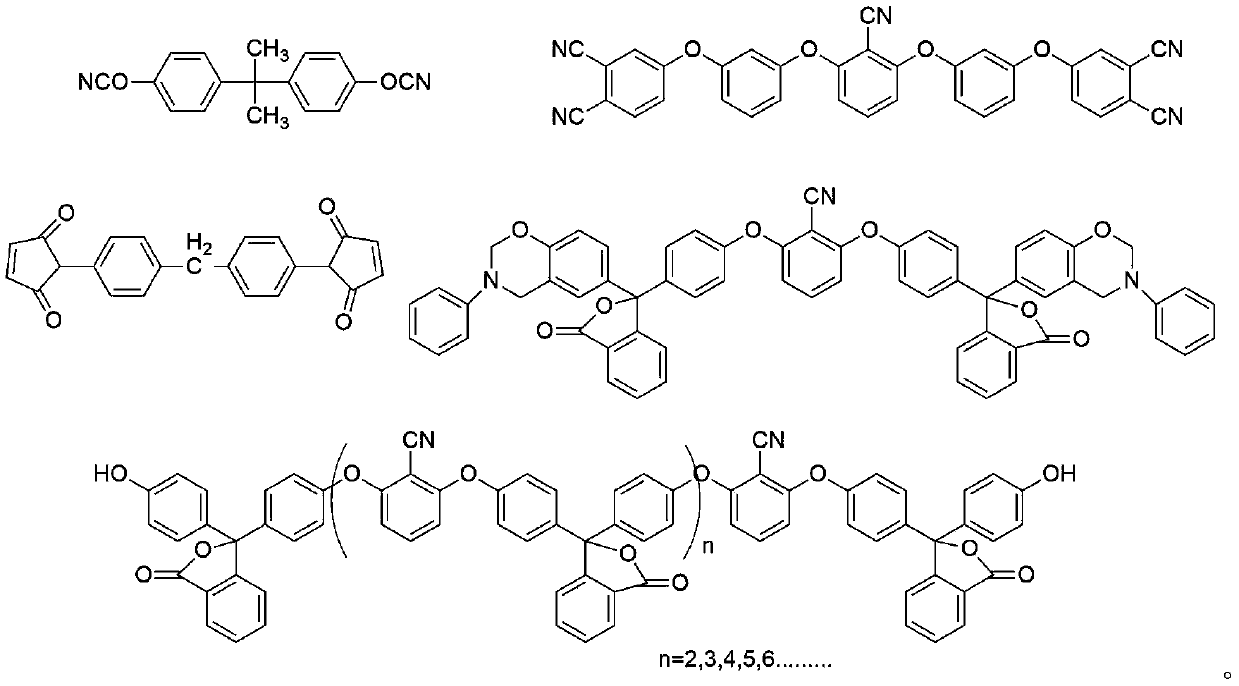

Embodiment 1

[0051] (1) 14 grams of benzoxazine-containing nitrile-based resin and 6 grams of chain extender (containing aryl ether nitrile segmented nitrile-based resin) were sequentially added to 15 ml of N,N-dimethylformamide to obtain a uniform transparent solution;

[0052] (2) Add 2ml of toluene solvent to the homogeneous solution in (1), and adjust the reflux temperature of the system within the range of 120-155°C;

[0053] (3) Slowly raise the temperature of the obtained solution system, and control the temperature of the system within the range of 130-140° C. to stir and react for 2 hours to obtain a uniform solution with a slightly increased viscosity;

[0054] (4) Continue to raise the temperature of the solution system obtained in (3) to 150-155° C., stir vigorously, maintain the system temperature and stir for 2 hours to obtain a viscous solution system with significantly increased viscosity;

[0055] (5) Maintain the stirring rate, adjust the reaction device, connect the wate...

Embodiment 2

[0060] (1) 14 grams of benzoxazine-containing nitrile-based resin and 5 grams of chain extender (bisphenol A cyanate) were sequentially added to 15 ml of N,N-dimethylformamide to obtain a uniform transparent solution;

[0061] (2) Add 2ml of toluene solvent to the homogeneous solution in (1), and adjust the reflux temperature of the system within the range of 120-155°C;

[0062] (3) Slowly raise the temperature of the obtained solution system, and control the temperature of the system within the range of 130-140° C. to stir and react for 1 hour to obtain a uniform solution with a slightly increased viscosity;

[0063] (4) Continue to raise the temperature of the solution system obtained in (3) to 150-155° C., stir vigorously, and maintain the temperature of the system while stirring and reacting for 3 hours to obtain a viscous solution system with significantly increased viscosity;

[0064] (5) Maintain the stirring rate, adjust the reaction device, connect the water separator...

Embodiment 3

[0069] (1) 14 grams of benzoxazine-containing nitrile-based resin and 4 grams of chain extender (phenolphthalein type aryl ether nitrile) were successively added to 20 ml of N,N-dimethylformamide to obtain a uniform transparent solution;

[0070] (2) Add 3ml of toluene solvent to the homogeneous solution in (1), and adjust the reflux temperature of the system within the range of 120-155°C;

[0071] (3) Slowly raise the temperature of the obtained solution system, and control the temperature of the system within the range of 130-140° C. to stir and react for 2 hours to obtain a uniform solution with a slightly increased viscosity;

[0072] (4) Continue to raise the temperature of the solution system obtained in (3) to 150-155° C., stir vigorously, and maintain the temperature of the system while stirring and reacting for 3 hours to obtain a viscous solution system with significantly increased viscosity;

[0073] (5) Maintain the stirring rate, adjust the reaction device, connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com