Preparation method of C@Ni composite material and electromagnetic shielding film

A composite material and electromagnetic shielding technology, applied in chemical instruments and methods, other chemical processes, etc., can solve secondary EMI pollution and other problems, and achieve the effect of strong shielding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

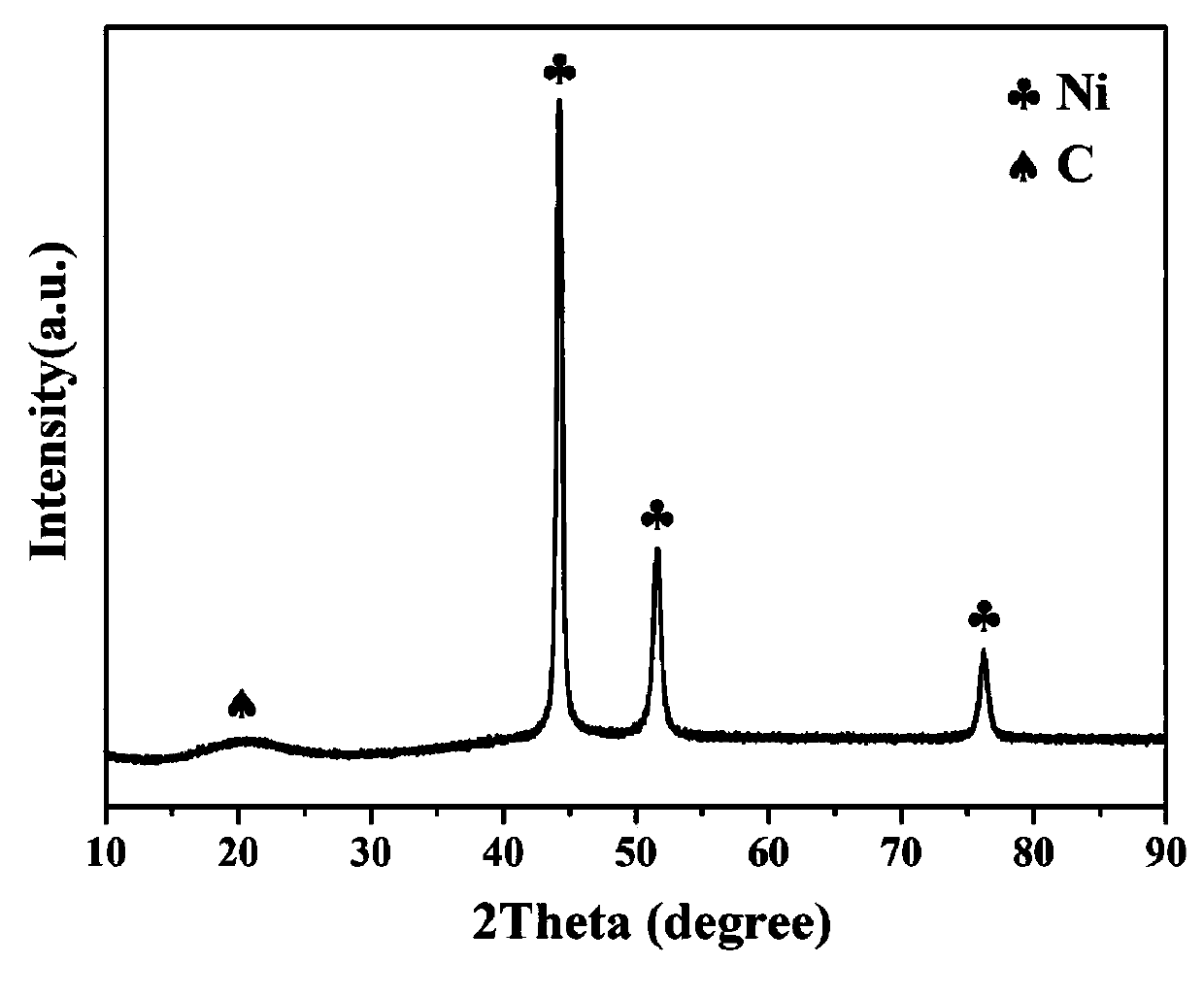

[0043] A preparation method of C@Ni composite material, comprising the following steps:

[0044] (1) First mix 0.1-0.3mL of ammonia water and ethanol aqueous solution (28mL), and stir magnetically at room temperature for 1 hour, in which 8mL of ethanol and 20mL of water are in the ethanol aqueous solution, a total of 28mL;

[0045] (2) adding formaldehyde solution and resorcinol to the mixed solution of (1) above, and stirring magnetically at room temperature for 24 hours;

[0046] (3) Transfer the solution obtained in step (2) to a polytetrafluoroethylene reactor, and control the temperature in a drying oven at 100°C for hydrothermal reaction for 24 hours;

[0047] (4) After the hydrothermal reaction finishes, take out the precipitate wherein, clean, dry, obtain monodisperse resorcinol-formaldehyde resin (RF) ball;

[0048] (5) Under an inert atmosphere, calcinate the RF spheres prepared in (4) at 600°C for 6h to obtain precursor C spheres. During calcination, first raise th...

Embodiment 2

[0055] The difference with embodiment 1 is: the NiCl in the step (4) 2 ·6H 2 The amount of O was changed to 1 mmol, and the obtained C@Ni composite material was denoted as A-2 sample; the others were the same as in Example 1.

Embodiment 3

[0057] The difference with embodiment 1 is: the NiCl in the step (4) 2 ·6H 2 The amount of O was changed to 1.5 mmol, and the obtained C@Ni composite material was denoted as A-3 sample; others were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com