Water-based two-component epoxy primer-topcoat paint

A water-based two-component, epoxy technology, applied in the field of coatings, can solve problems such as gaps, unpleasant air temperature, single-coat water-based paints that cannot take into account corrosion resistance and weather resistance, etc., achieve the best paint film performance and reduce the use of co-solvents Effect of demand, good sprayability and sag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The light gray water-based two-component epoxy bottom-surface-in-one paint used by a certain coating company in this embodiment consists of the following components:

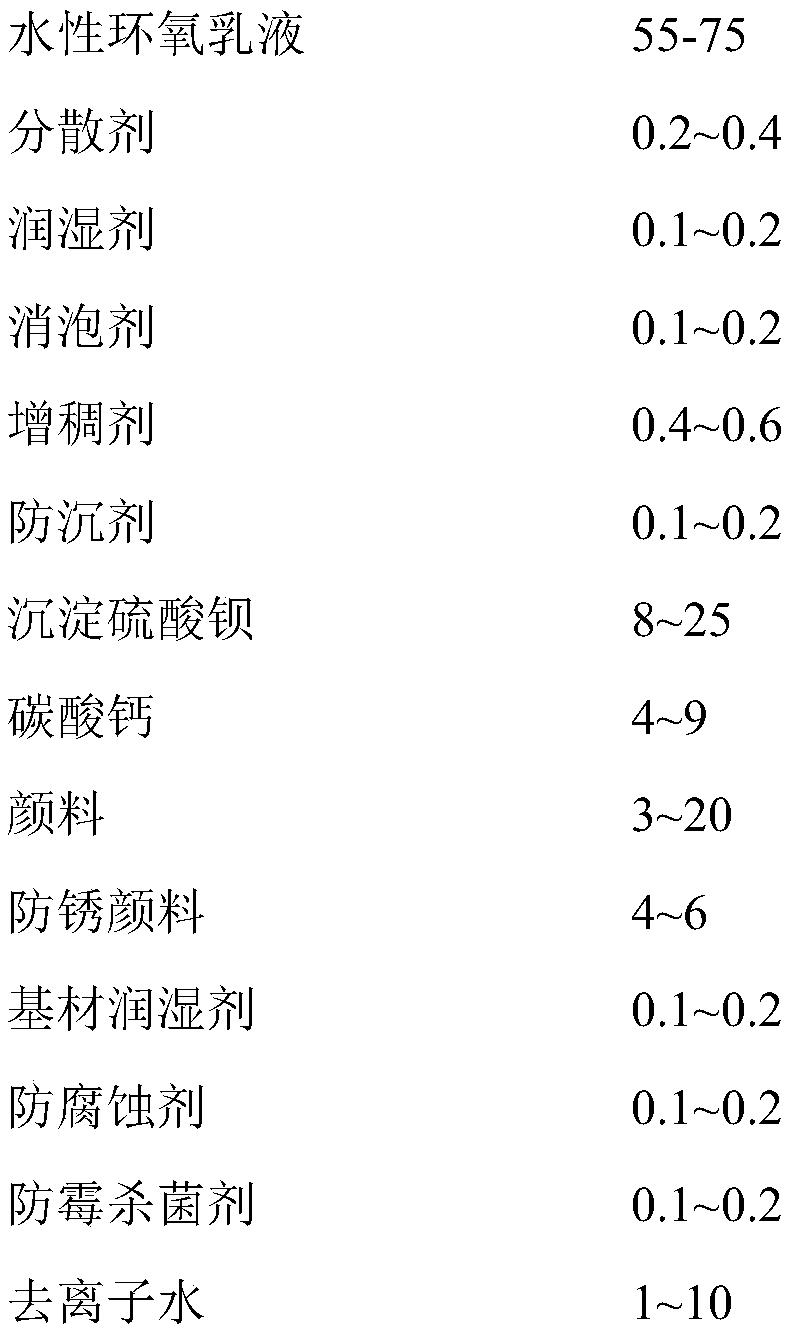

[0028] Group A includes the following substances, and the mass fractions of each substance are:

[0029]

[0030] Component B includes the following substances, and the mass fractions of each substance are:

[0031] Modified amine epoxy curing agent 50

[0032] Fatty alcohol polyoxyethylene ether phosphate ester / salt 0.25

[0033] Deionized water 49.75

[0034] Mix components A and B according to the mass ratio of 10:1 to obtain the water-based two-component epoxy primer in this application.

Embodiment 2

[0036] In this embodiment, the iron red water-based two-component epoxy bottom and surface all-in-one paint used by a certain company consists of the following components:

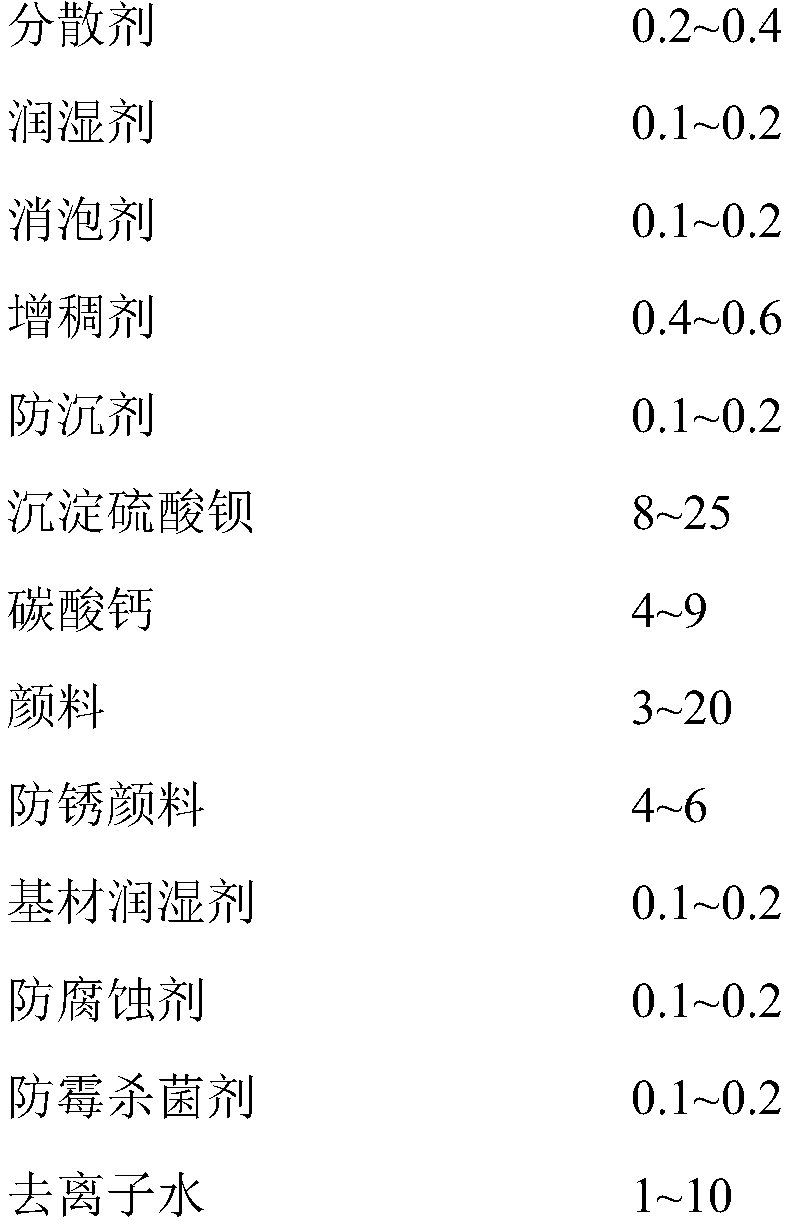

[0037] Group A includes the following substances, and the mass fractions of each substance are:

[0038]

[0039] Component B includes the following substances, and the mass fractions of each substance are:

[0040] Modified amine epoxy curing agent 50

[0041] Fatty alcohol polyoxyethylene ether phosphate ester / salt 0.5

[0042] Deionized water 49.5

[0043] Mix components A and B according to the mass ratio of 9:1 to obtain the water-based two-component epoxy primer in this application.

Embodiment 3

[0045] The engineering yellow water-based two-component epoxy bottom surface integration paint used by a certain company in this embodiment consists of the following components:

[0046] Group A includes the following substances, and the mass fractions of each substance are:

[0047]

[0048]

[0049] Component B includes the following substances, and the mass fractions of each substance are:

[0050] Modified amine epoxy curing agent 50

[0051] Fatty alcohol polyoxyethylene ether phosphate ester / salt 0.1

[0052] Deionized water 49.9

[0053] Mix components A and B according to the mass ratio of 6:1 to obtain the water-based two-component epoxy primer in this application.

[0054] The performance of the water-based two-component epoxy bottom-surface-in-one paint prepared in the above three examples was tested, and the test results are shown in the table below. It can be seen from the table below that the VOC content of the water-based two-component epoxy primer and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com