Harmful gas treatment device used for earth pressure balance shield and treatment method

An earth pressure balance shield and harmful gas technology, applied in mining equipment, measuring equipment, earthwork drilling and mining, etc., can solve the problems of no explosion protection, gas explosion, etc., and achieve the effect of ensuring safety and good detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

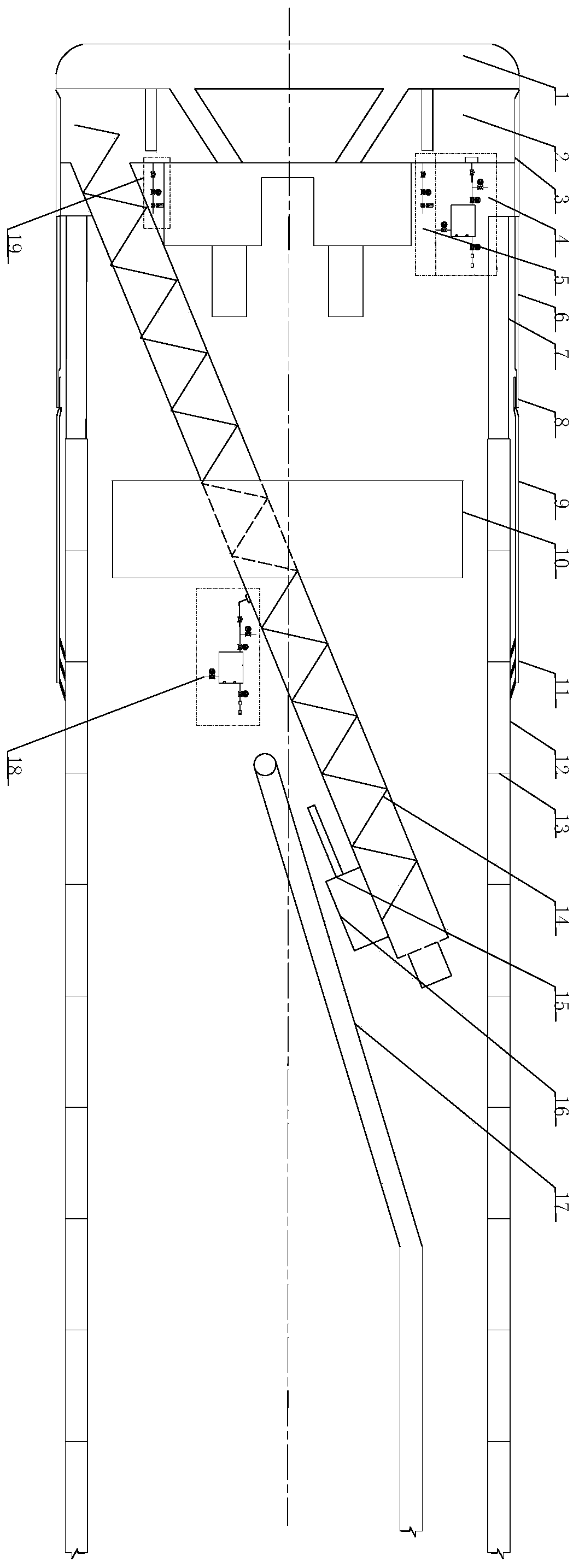

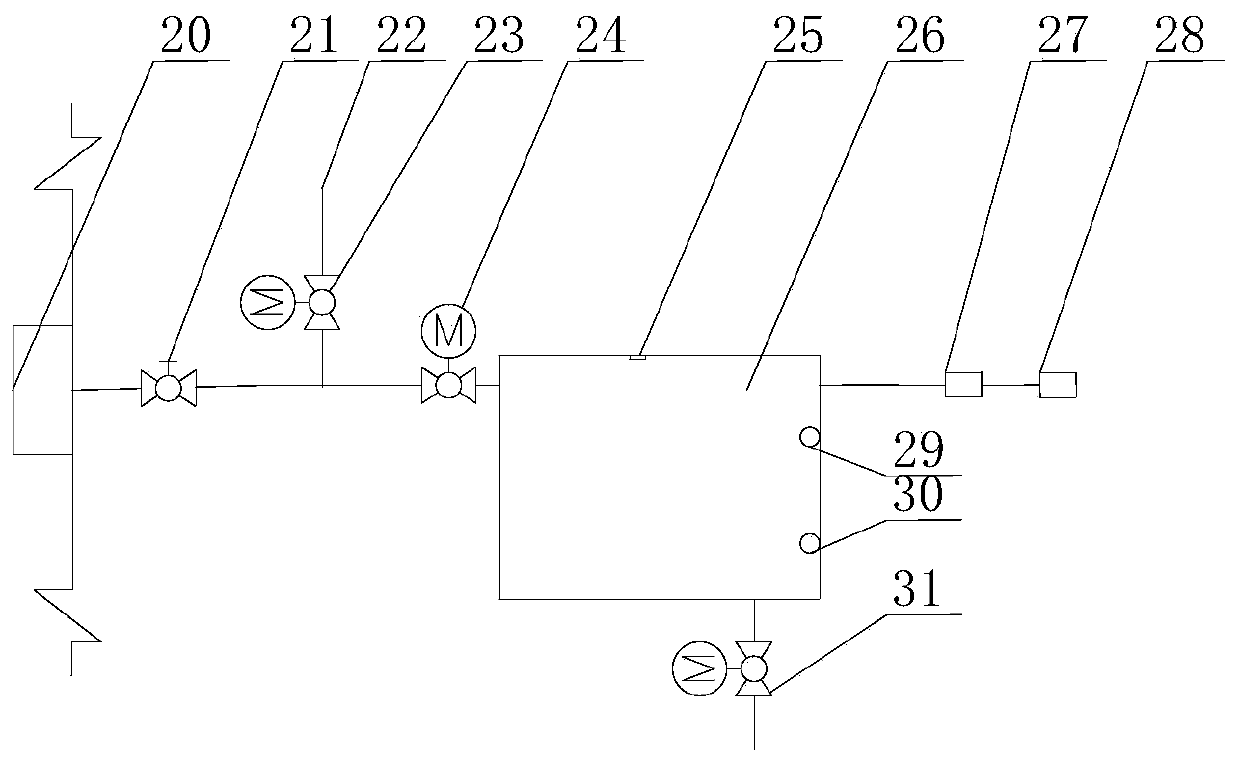

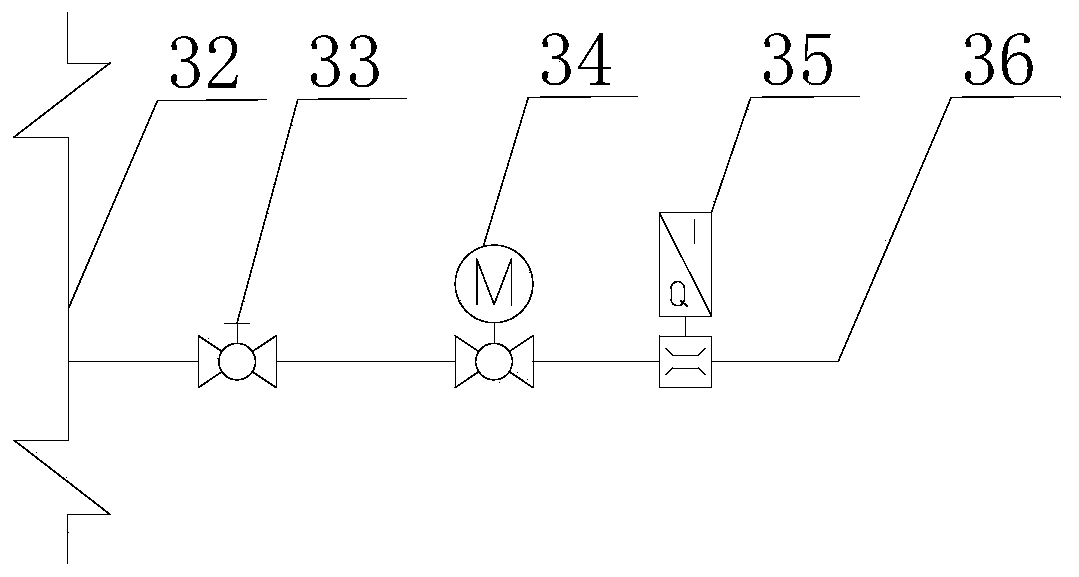

[0032] Such as figure 1 and figure 2 As shown, the earth pressure balance shield includes a cutter head 1, a front shield 3, a middle shield 6, a shield tail 9, an assembly machine 10, a propulsion cylinder 7, a segment 12, and a belt conveyor arranged under the slag outlet 16 of the screw conveyor 17, etc., a harmful gas treatment device for earth pressure balance shield tunneling of the present invention, including a gas detection device, the gas detection device includes a filter screen, a water inlet pipe 22, a first valve 23, a second valve 24, and a storage box 26 , a gas sensor and a third valve 31;

[0033] The front end of the connecting pipeline is provided with a strainer, and the connecting pipeline is communicated with the water inlet pipe 22; the first valve 23 is set on the water inlet pipe 22, the second valve 24 is set on the connecting pipeline, and the connecting pipeline is connected with the storage box 26; the storage box 26 The bottom is connected wit...

Embodiment 2

[0039] During the construction of the earth pressure balance shield, the main positions where gas and other harmful gases enter the tunnel are: screw conveyor slag outlet 16, hinge seal 8, shield tail seal 11, and segment joint 13. Hinged seal 8, shield tail 9 seal, and segment joint 13 all adopt sealing devices, and under the premise that the sealing devices are not damaged, the permeation amount of gas and other harmful gases can basically be ignored. Therefore, the screw conveyor 14, especially its slag outlet, is likely to carry a large amount of harmful gas, such as gas, along with the output of the slag. In addition, in the soil chamber 2 of the shield machine, a large amount of mixed gas tends to exist in the upper part of the soil chamber 2 . Aiming at this phenomenon, the present invention optimizes the detection position.

[0040] The gas detection device comprises a first gas detection device 4 and a second gas detection device 18 with the same structure, that is, ...

Embodiment 3

[0042] For the first gas detection device 4 and the second gas detection device 18, the following settings have also been made:

[0043] The connecting pipeline is connected with the top of the storage box 26, and the gravity of the medium is used to form natural stratification. The heavier medium such as muddy water sinks to the bottom of the storage box 26, and the mixed gas naturally floats on the top of the storage box 26. The inlet of the detection pipeline is also arranged on the upper part of the storage box 26 to facilitate the mixed gas to enter the detection pipeline.

[0044] A first cut-off valve 21 is arranged on the connecting pipeline, and the first shut-off valve 21 is close to the earth compartment partition 32 of the earth pressure balance shield, and is located before the connection node between the connecting pipeline and the water inlet pipe 22 .

[0045] The second valve 24 is located close to the storage tank 26 and after the connection node of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com