Packaging structure forming method

A technology of packaging structure and contact structure, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problem that the electromagnetic shielding effect needs to be improved, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] As mentioned in the background, the effect of existing electromagnetic shielding still needs to be improved.

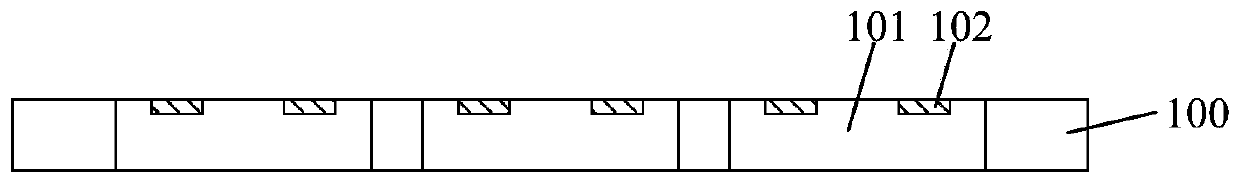

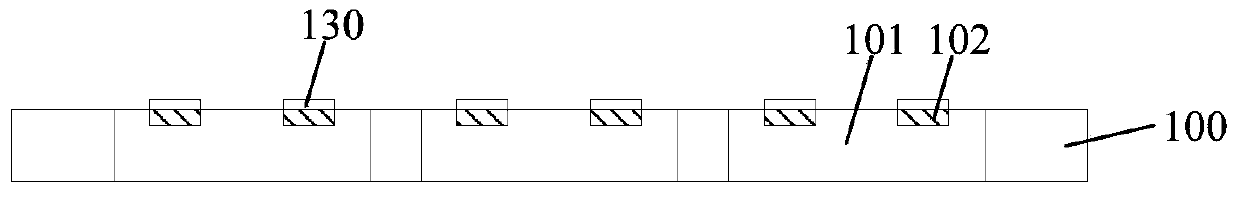

[0040] The study found that the existing magnetic field shielding layer is generally formed by sputtering process. Since the thickness of the semiconductor package structure is generally thick, and the semiconductor package structure is generally rectangular, the semiconductor package structure has multiple corners and the side wall is relatively steep. When the magnetic field shielding layer covering the semiconductor package structure is formed by sputtering, the thickness of the formed magnetic field shielding layer is likely to be uneven, and the edge of the semiconductor package structure may not be covered, thus making it difficult to guarantee the shielding effect of the magnetic field shielding layer.

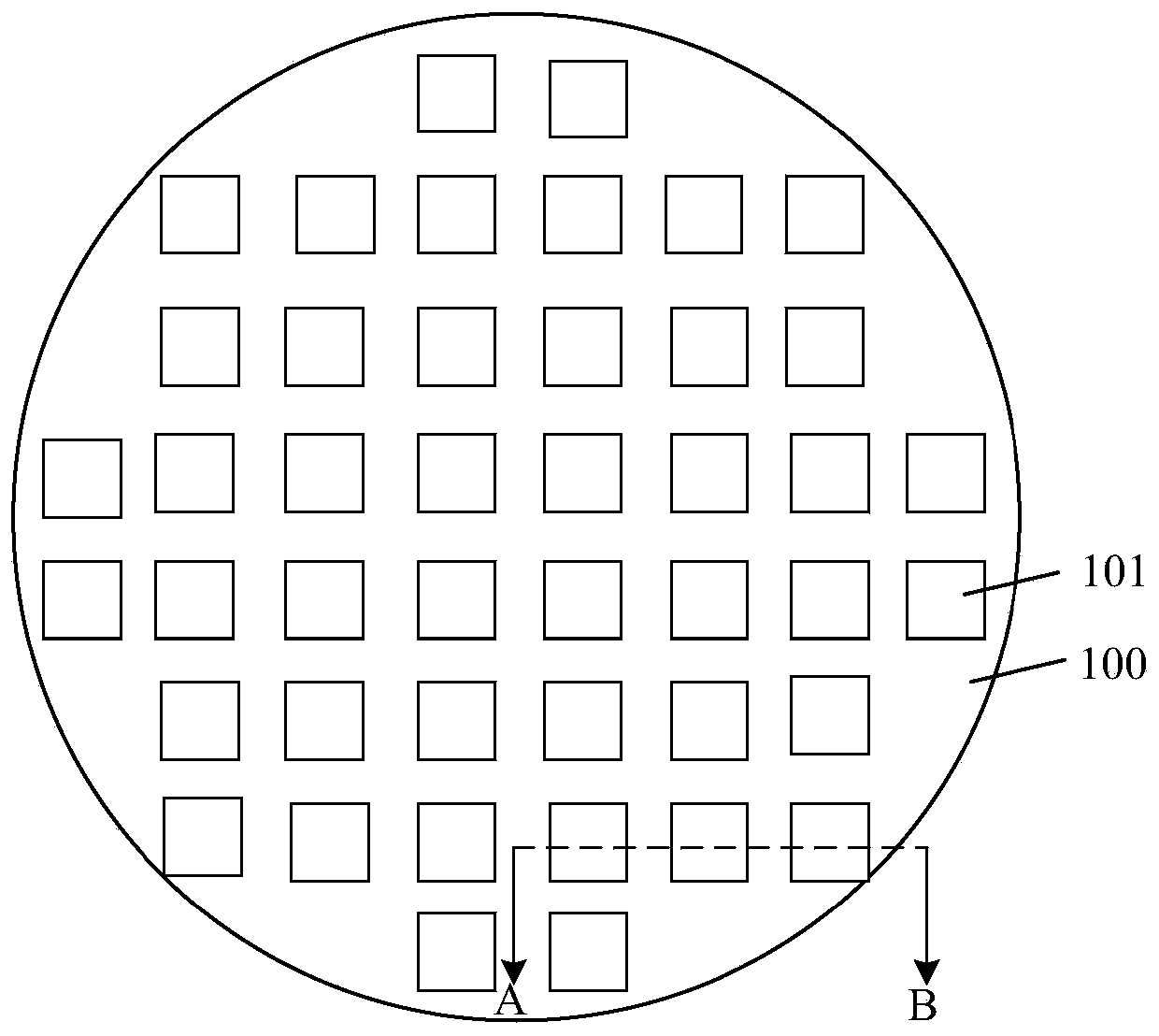

[0041] Therefore, the present invention provides a packaging structure and a forming method thereof. In the forming method, after the first plastic seali...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap