A solidification and stabilization material for controlling arsenic pollution and its preparation method

A technology of arsenic pollution and mechanical activation, applied in the field of soil remediation, can solve the problems of low practicability, difficulty in production and application, and high price, and achieve the effect of simple manufacture, obvious stabilization effect, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

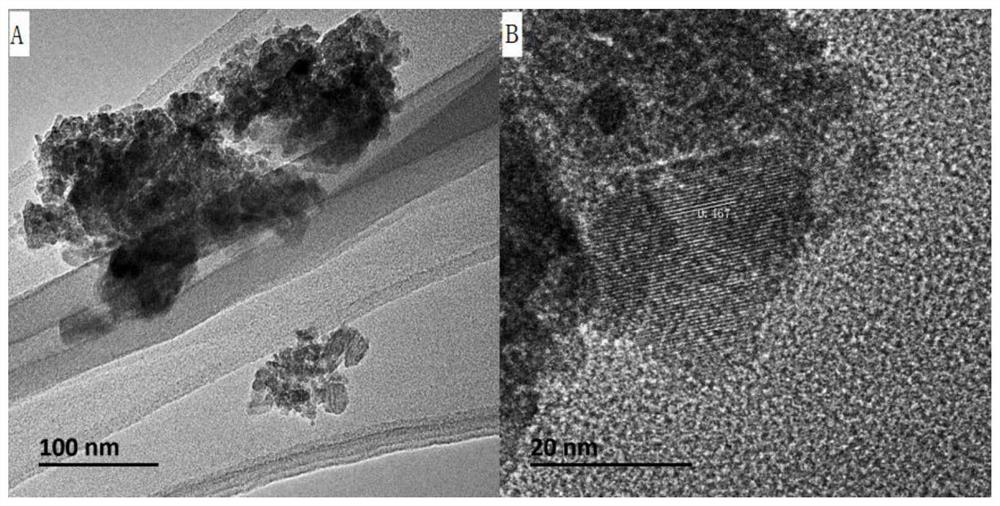

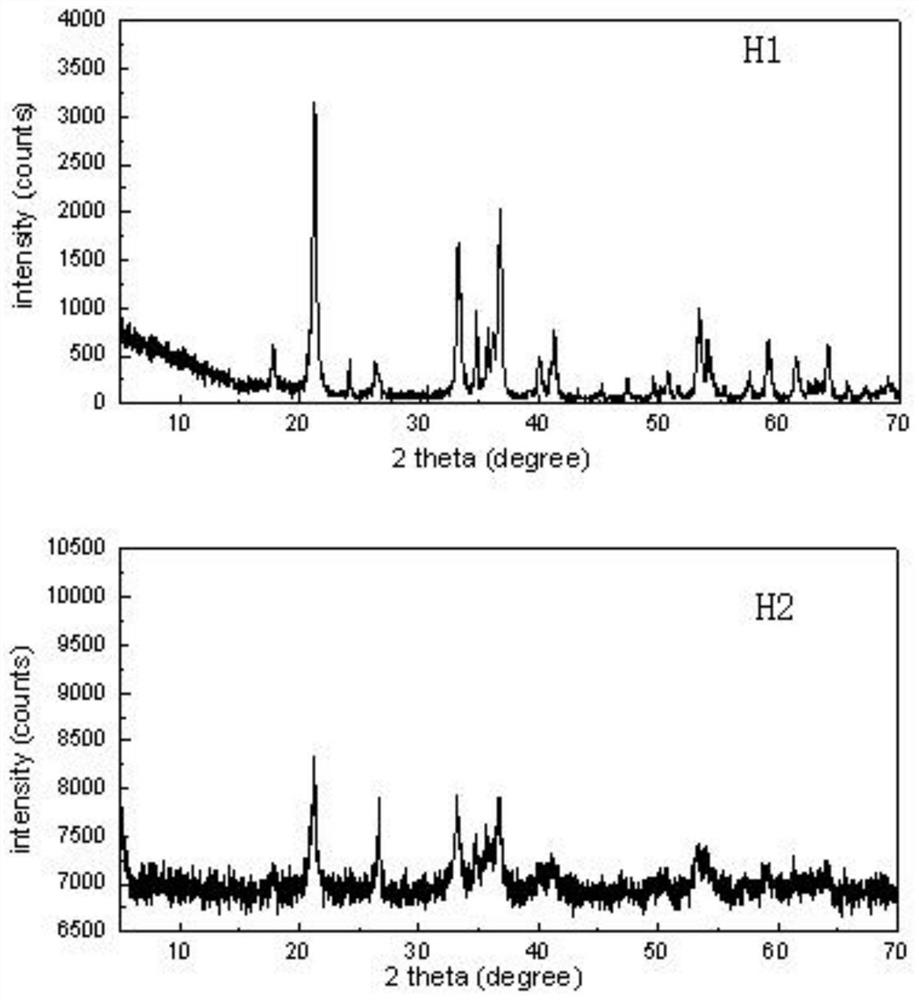

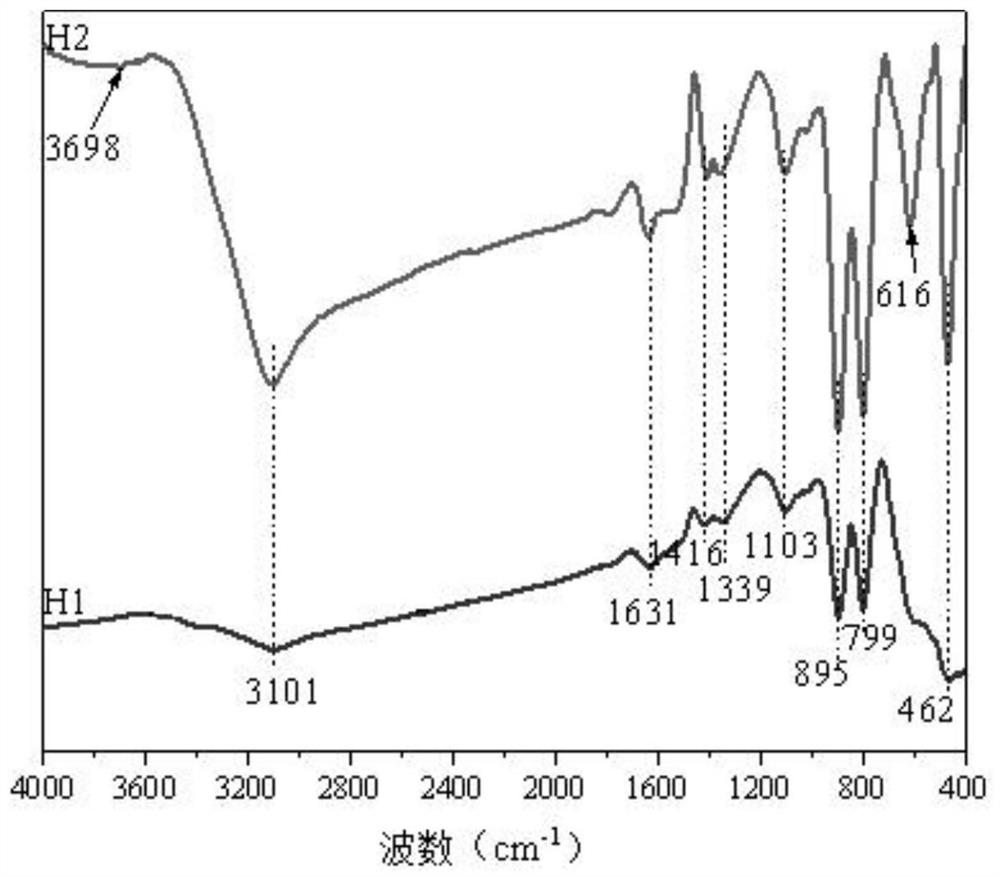

[0030] A curing and stabilizing material for controlling arsenic pollution, comprising mechanically activated limonite with an average particle size of 0.2 μm obtained through mechanical activation. Specifically, when the average particle size of the mechanically activated limonite is 0.2 μm, the mechanically activated limonite particles with a particle size of less than 1 μm account for 95% of the total amount (by mass), and the content of Fe element is 63.8 %, containing goethite phase components, uniform particle size and low crystallinity, at this time, the adsorption force on As is the best. Its adsorption capacity for As(V) can reach 8.26-8.34mg·g -1 , the adsorption capacity for As(III) can reach 8.73-9.14mg·g -1 .

Embodiment 2

[0032] A method for preparing a solidified and stabilized material for controlling arsenic pollution, comprising the steps of:

[0033] Step 1: selecting natural limonite with an iron content of 60-70%, smashing it and coarsely grinding it into powdery limonite with larger particle size;

[0034] Step 2: sieving the powdery limonite to obtain fine powder limonite;

[0035] Step 3: Put the fine powder limonite in the Miqi YXQM-2L planetary ball mill for mechanical activation. The ball mill cylinder and balls are made of agate, and the balls are small balls. The ball-to-material ratio is set to 10:1 , the revolution speed of the ball mill is set to 320r / min, and the rotation speed is set to 640r / min;

[0036] And add dehydrated alcohol in mechanical activation process as dispersion medium, the solid-liquid ratio of its fine powder limonite and dehydrated alcohol is 5:4, and solid-liquid ratio unit is g:mL; Fine powder limonite is in Perform mechanical activation in a ball mill...

Embodiment 3

[0040] A method for preparing a solidified and stabilized material for controlling arsenic pollution, comprising the steps of:

[0041] Step 1: selecting natural limonite with an iron content of 60-70%, smashing it and coarsely grinding it into powdery limonite with larger particle size;

[0042] Step 2: passing the powdery limonite through a 200-mesh sieve to obtain fine powder limonite;

[0043] Step 3: Place the fine powder limonite in the Miqi YXQM-2L planetary ball mill for mechanical activation. The ball mill cylinder and balls are made of agate, and the balls are small balls. The ball-to-material ratio is set to 10:1 , the revolution speed of the ball mill is set to 320r / min, and the rotation speed is set to 640r / min;

[0044] And in mechanical activation process, add dehydrated alcohol as dispersion medium, the solid-liquid ratio of described fine powder limonite and described dehydrated alcohol is 5:4, and solid-liquid ratio unit is g:mL; Fine powder brown The iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com