Disinfectant fluid production process

A production process and disinfection water technology, applied in the direction of disinfectants, biocides, plant growth regulators, etc., can solve the problems of slow action and incomplete sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

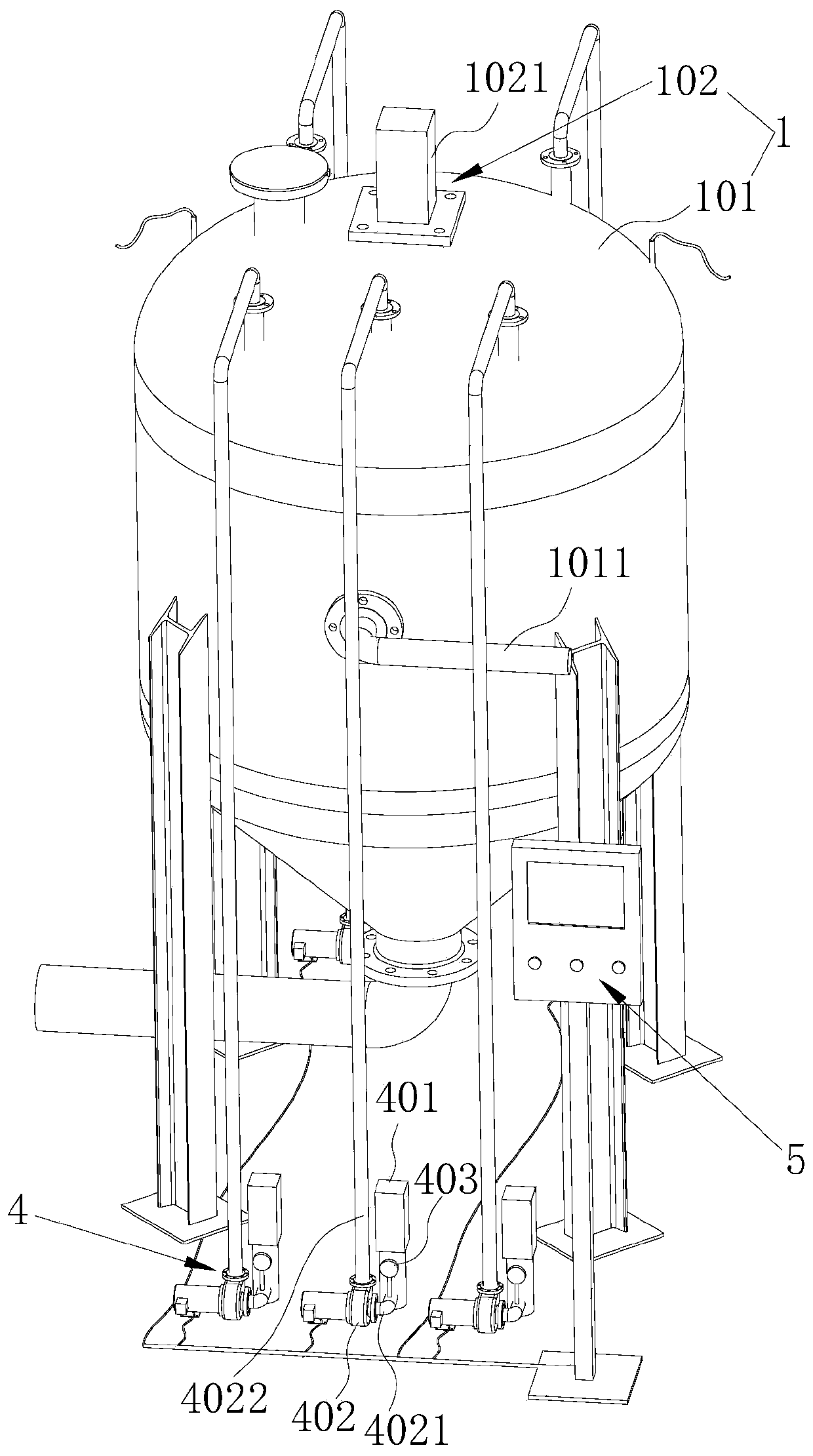

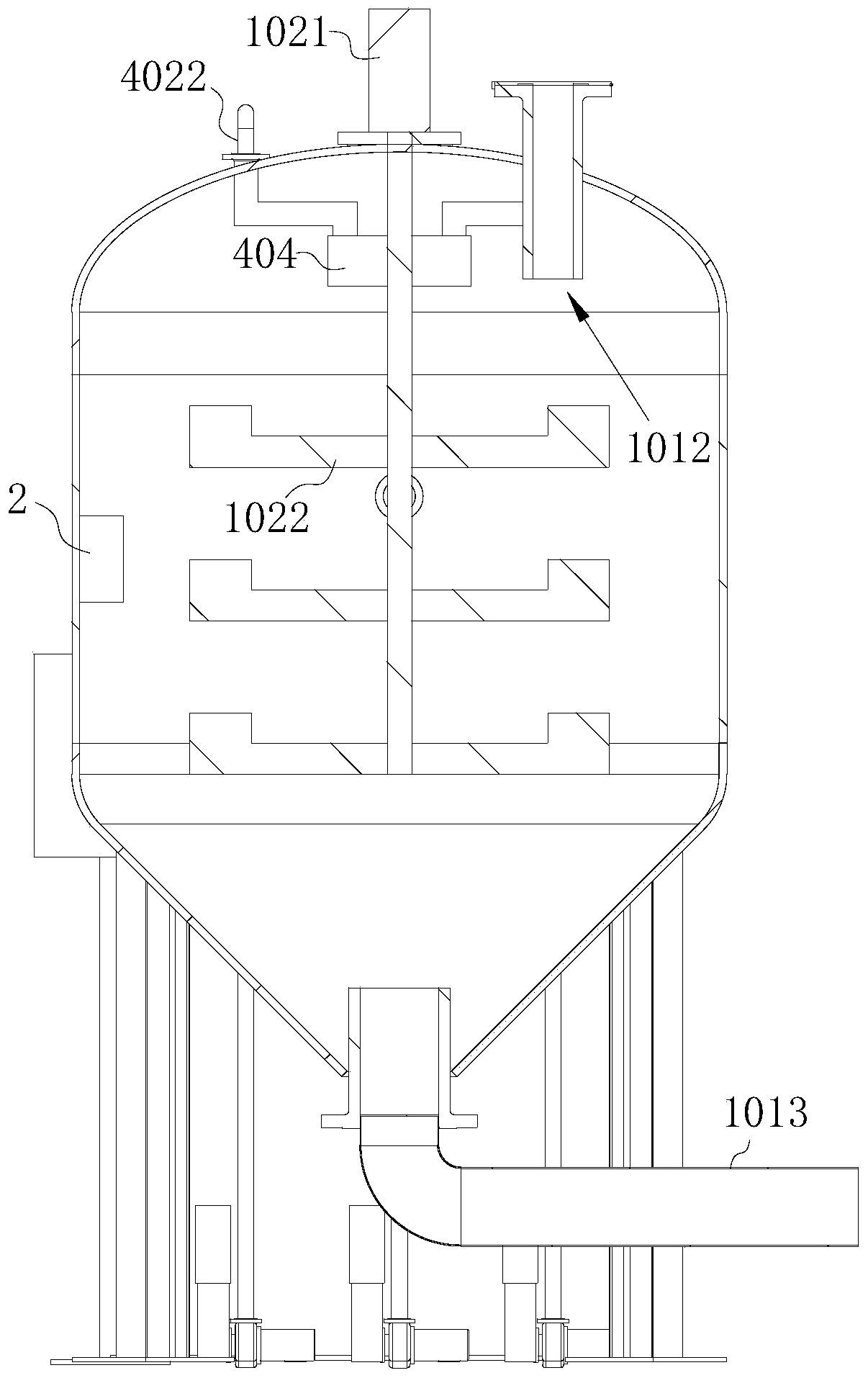

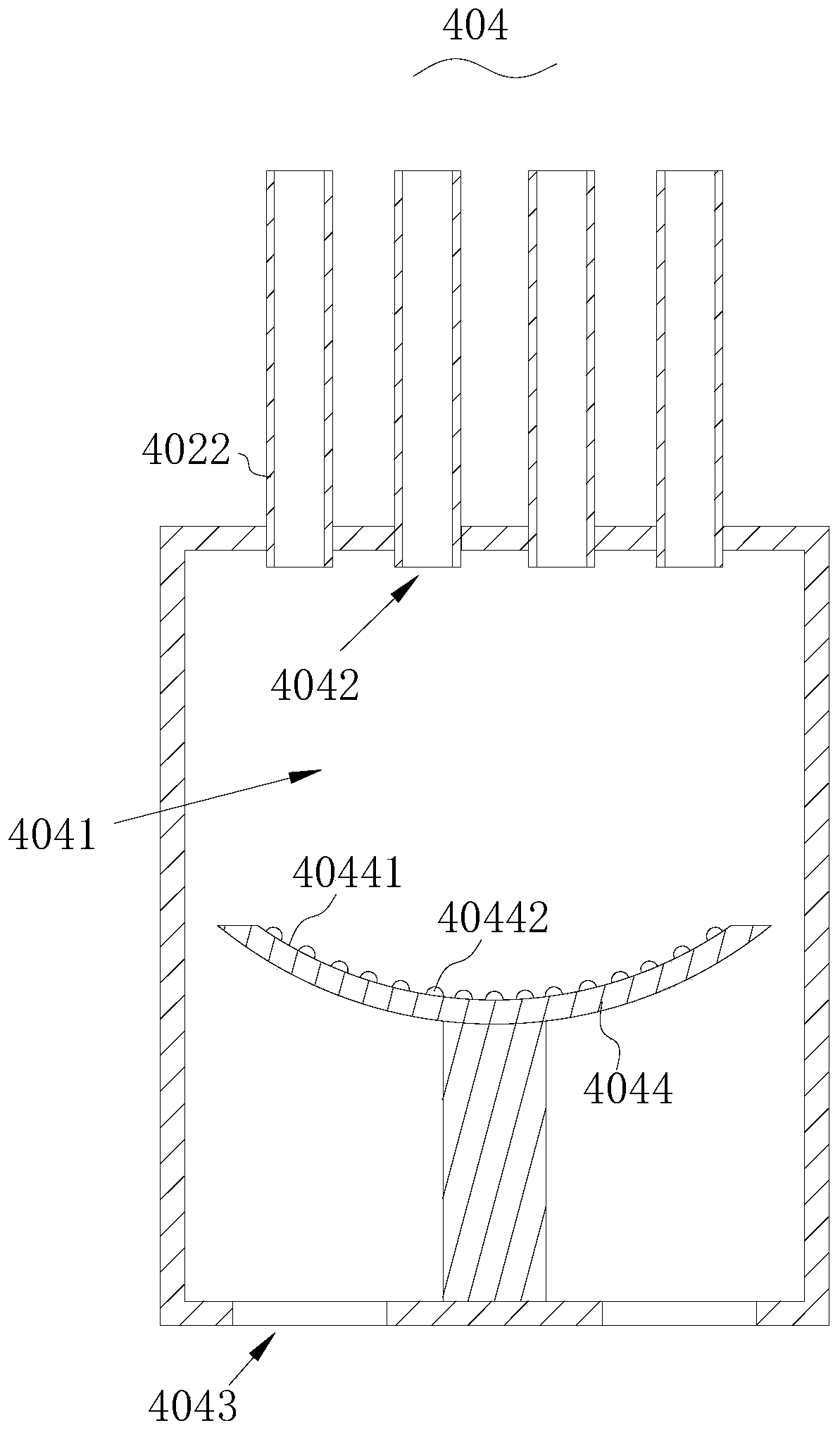

[0090] refer to figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 as well as Figure 7 , This embodiment discloses a chlorine-containing disinfection water production equipment, including a stirring tank 1, an available chlorine detection sensor 2 and a PH meter 3 arranged in the stirring tank 1, a feeding device 4 and an electronic control device 5.

[0091] refer to figure 1 , figure 2 , Figure 4 as well as Figure 5 The stirring tank 1 includes a tank body 101 and an electric stirring assembly 102 arranged on the tank body 101. The electric stirring assembly 102 includes a stirring motor 1021 and a stirring paddle 1022 connected to the stirring motor 1021. The stirring motor 1021 is electrically connected to the electronic control device 5 connected, and the stirring motor 1021 is controlled by the electronic control device 5, and the electronic control device 5 controls the stirring motor 1021 to work at a preset stirring time and stirring speed.

[0092]...

Embodiment 2

[0129] refer to Figure 11 , this embodiment discloses another available chlorine detection sensor for chlorine-containing disinfection water production equipment. Based on the above-mentioned embodiment, the difference from the above-mentioned embodiment is that the liquid guide plate 801 is an L-shaped plate 18, and the L-shaped plate The component 18 includes a first structure part 1801 and a second structure part 1802. The first structure part 1801 overlaps on the step part 2023, the bottom of the second structure part 1802 abuts against the installation shoulder 2022, the first structure part 1801, the second structure part 1801 The second structure part 1802 , the installation shoulder part 2022 and the step part 2023 enclose the liquid guiding cavity 8011 .

[0130] reference image Figure 11 as well as Figure 12 , the first structure part 1801 is provided with a first connection protrusion 18011, and the step part 2023 is provided with a first groove part (not marke...

Embodiment 3

[0133] This embodiment discloses a disinfection water production process based on the chlorine-containing disinfection water production equipment of the above-mentioned embodiments, including:

[0134] S1: Preparation of liquid raw materials

[0135]According to the disinfectant water formula of the prior invention application with application number 2019105191008, first, prepare solution A: add 3kg of sodium chloride, 8g of boron nitride and 500g of mannitol into 99.48L of water and stir evenly, and obtain solution A after fully mixing ;

[0136] The food-grade sodium hypochlorite solution with an available chlorine concentration of 10% is used as the B solution, and 0.2 L is taken;

[0137] Dodecyl dimethyl amine oxide is used as C solution, and 3kg is taken;

[0138] Glycerol is used as D solution, take 2kg;

[0139] 5M is used as a pH regulator, recorded as E solution;

[0140] Add the above liquid raw material components into the storage tanks of 5 feeding devices res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com