Energy-saving cement and preparation method therefor

A cement and raw material technology, applied in the field of energy-saving cement and its preparation, can solve the problems of unfavorable high compressive strength concrete mixture, steel slag utilization rate less than 17%, and large accumulation of steel slag, so as to achieve high compressive strength and increase strength , The effect of improving productivity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

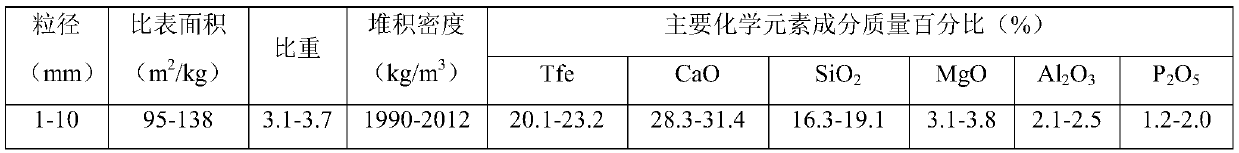

Method used

Image

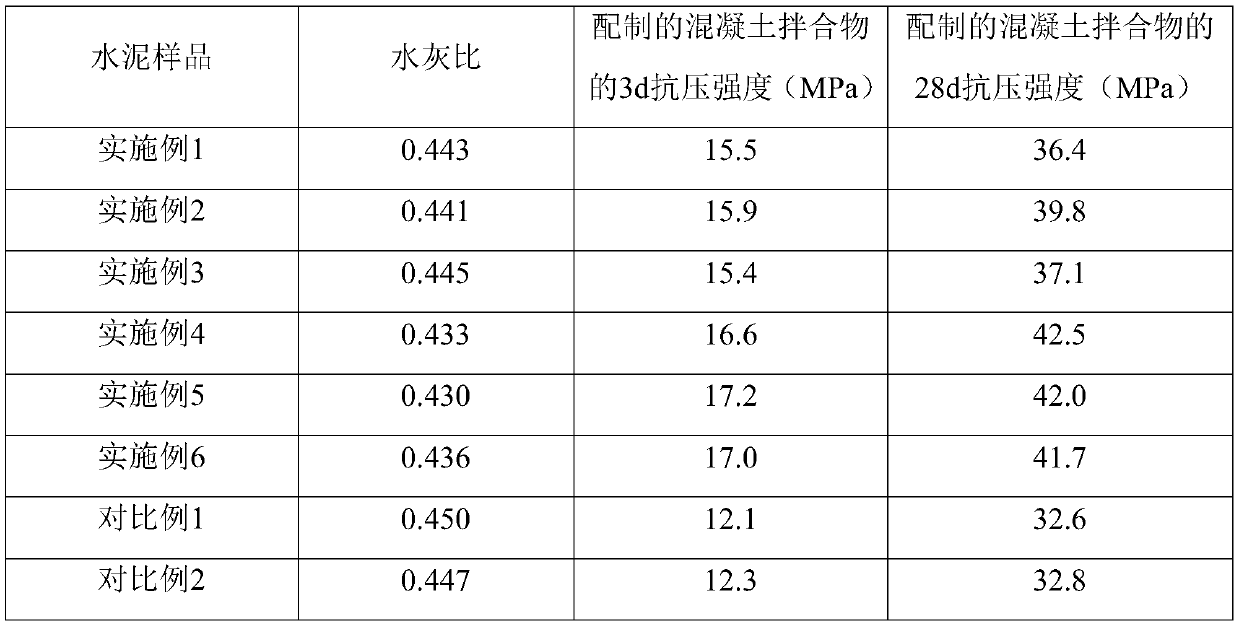

Examples

Embodiment 1

[0048] An energy-saving cement, comprising the following raw material components in parts by weight: 73 parts of Portland cement clinker, 8 parts of gypsum, 1 part of limestone, 10 parts of mineral powder, 1 part of sodium hydroxide, and 20 parts of steel slag powder;

[0049] The preparation of the steel slag powder includes the following steps: the steel slag raw material is ground to obtain a steel slag powder with a particle size of ≤0.5mm, and during the grinding process, a grinding aid combination additive accounting for 1% by weight of the steel slag raw material is added, wherein the grinding aid The combined additive includes fly ash and colloidal graphite powder, and the mass ratio of fly ash and colloidal graphite powder is 1:0.3;

[0050] The preparation method of energy-saving cement comprises the following steps:

[0051] a, preparing steel slag powder;

[0052] b. After mixing the raw material components of the energy-saving cement, the energy-saving cement is ...

Embodiment 2

[0054] An energy-saving cement, comprising the following raw material components in parts by weight: 80 parts of Portland cement clinker, 5 parts of gypsum, 3 parts of limestone, 7 parts of mineral powder, 3 parts of sodium hydroxide, and 17 parts of steel slag powder;

[0055] The preparation of the steel slag powder includes the following steps: the steel slag raw material is ground to obtain a steel slag powder with a particle size of ≤0.5 mm; The combined additive includes fly ash and colloidal graphite powder, and the mass ratio of fly ash and colloidal graphite powder is 1:1;

[0056] The preparation method of energy-saving cement comprises the following steps:

[0057] a, preparing steel slag powder;

[0058] b. After mixing the raw material components of the energy-saving cement, the energy-saving cement is prepared through cement grinding.

Embodiment 3

[0060] An energy-saving cement, comprising the following raw material components in parts by weight: 86 parts of Portland cement clinker, 2 parts of gypsum, 5 parts of limestone, 5 parts of mineral powder, 5 parts of sodium hydroxide, and 15 parts of steel slag powder;

[0061] The preparation of the steel slag powder includes the following steps: the steel slag raw material is ground to obtain a steel slag powder with a particle size of ≤0.5 mm; The combined additive includes fly ash and colloidal graphite powder, and the mass ratio of fly ash and colloidal graphite powder is 1:0.3;

[0062] The preparation method of energy-saving cement comprises the following steps:

[0063] a, preparing steel slag powder;

[0064] b. After mixing the raw material components of the energy-saving cement, the energy-saving cement is prepared through cement grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com