A kind of polycarboxylate superplasticizer for pumping concrete with superfine sand for aluminum mold

A technology for pumping concrete and polycarboxylate, which is applied in the field of concrete, can solve the problems of poor concrete surface finish, high sensitivity of water reducing agent, high amount of cementitious materials, etc., achieve stable strength, reduce slump loss, reduce water The effect of rubber ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] C20 ultrafine sand pumping concrete preparation: the design density is 2355kg / m 3 , the amount of cementitious material is 305kg / m 3 , superplasticizer dosage 1.8%, water-binder ratio 0.59, sand rate 33.6%.

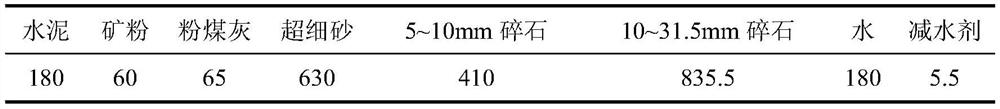

[0041] Table 1 Mix design of C20 superfine sand concrete (kg)

[0042]

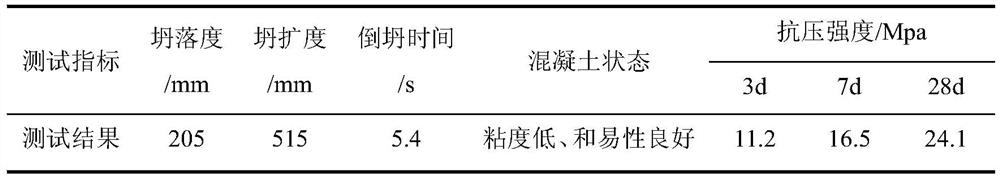

[0043] Table 2 Test results of C20 ultrafine sand concrete

[0044]

Embodiment 2

[0046] C30 superfine sand pumping concrete preparation: the design density is 2356kg / m 3 , the amount of cementitious material is 375kg / m 3 , superplasticizer dosage 1.73%, water-binder ratio 0.43, sand rate 30%.

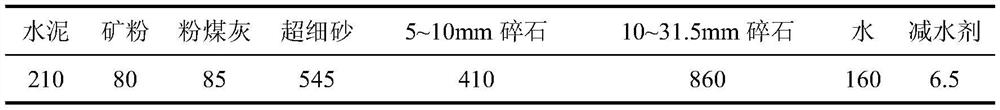

[0047] Table 3 Mix design of C30 superfine sand concrete (kg)

[0048]

[0049] Table 4 Test results of C30 ultrafine sand concrete

[0050]

Embodiment 3

[0052] C40 superfine sand pumping concrete preparation: the design density is 2384kg / m 3 , the amount of cementitious material is 400kg / m 3 , superplasticizer dosage 1.8%, water-binder ratio 0.4, sand rate 30%.

[0053] Table 5 Mix design of C40 superfine sand concrete

[0054]

[0055] Table 6 Test results of C40 ultrafine sand concrete

[0056]

[0057] The results of the implementation example illustrate: the implementation example combines the specific performance characteristics of the raw materials, adopts a lower sand rate and a reasonable continuous gradation for design, and uses calcium lignosulfonate modified polycarboxylate composite water reducer to ensure the original Without reducing the water reducing rate of polycarboxylate superplasticizer, the production cost of polycarboxylate superplasticizer is reduced, and it also has faster dispersion, lower viscosity and good slump retention effect, and ensures the concrete strength and surface finish. S95 gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com