Preparation and construction method of machine-sprayed phosphogypsum lightweight plastering mortar

A plastering mortar and phosphogypsum technology, applied in construction, building structure, covering/lining, etc., can solve the problems of easy bleeding of phosphogypsum mortar, poor phosphogypsum wrapping, rough surface morphology, etc., and achieve good adhesion Strength and anti-cracking effect, increase water retention effect, and improve the effect of anti-cracking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

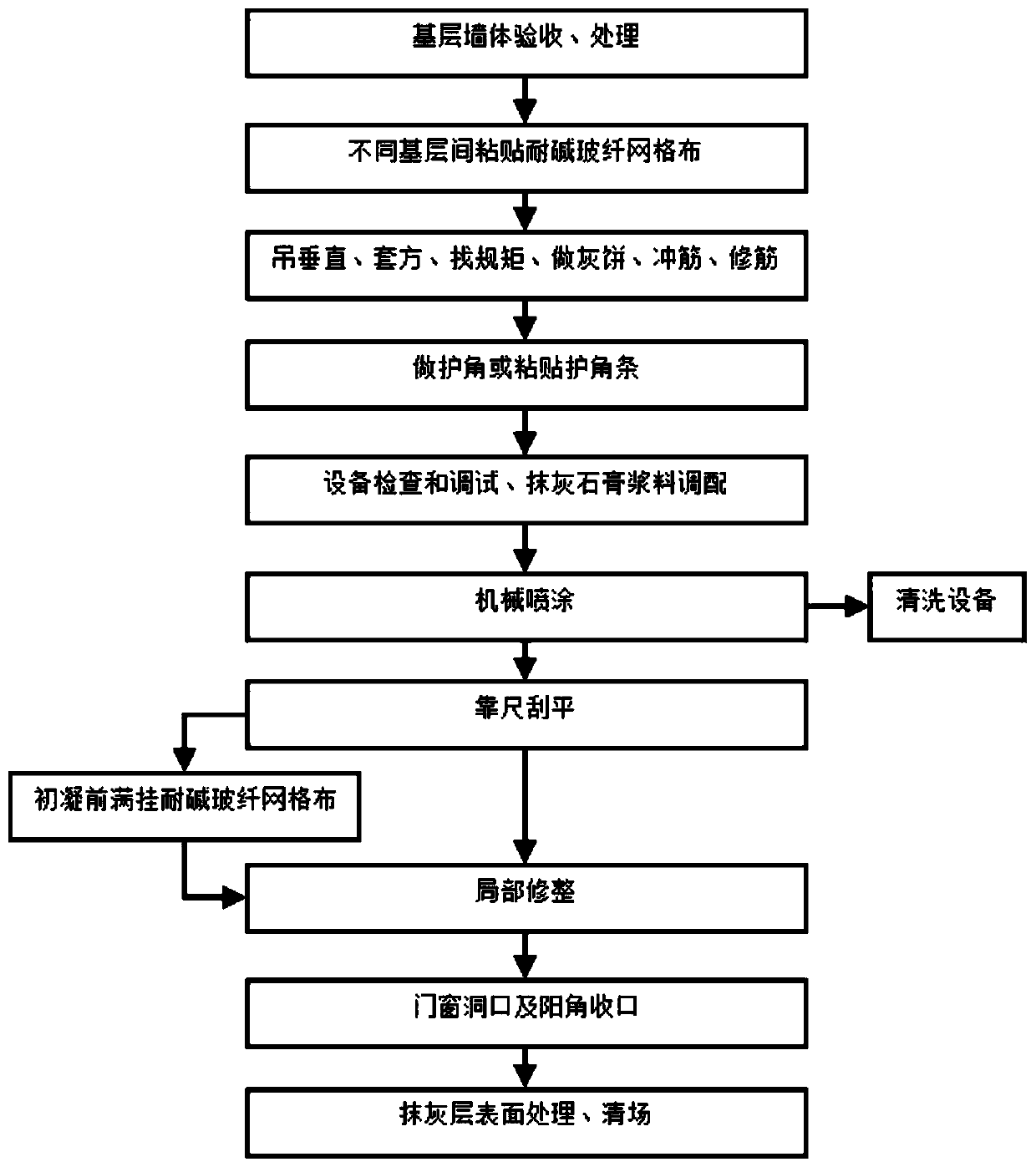

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, the preparation of 1 kg of machine-sprayed phosphogypsum lightweight plastering mortar is taken as an example, and the preparation method is as follows.

[0041] Weigh the ingredients according to the prescribed ratio, and the amount of each raw material is:

[0042] 85 parts of phosphogypsum, 5 parts of fine aggregate, 2 parts of inert admixture, 8 parts of vitrified microbeads, 0.1 part of retarder, 0.25 part of water retention agent, 0.05 part of anti-sagging agent (anti-sagging agent), strengthening agent 0.1 part, 0.4 part fiber, 0 part whitening agent.

[0043] Put the above-mentioned raw materials into the mixer in turn and mix them well. After they are fully mixed, the machine-sprayed plaster plaster mortar is obtained. When using, add a small amount of water to adjust and then machine-spray the construction.

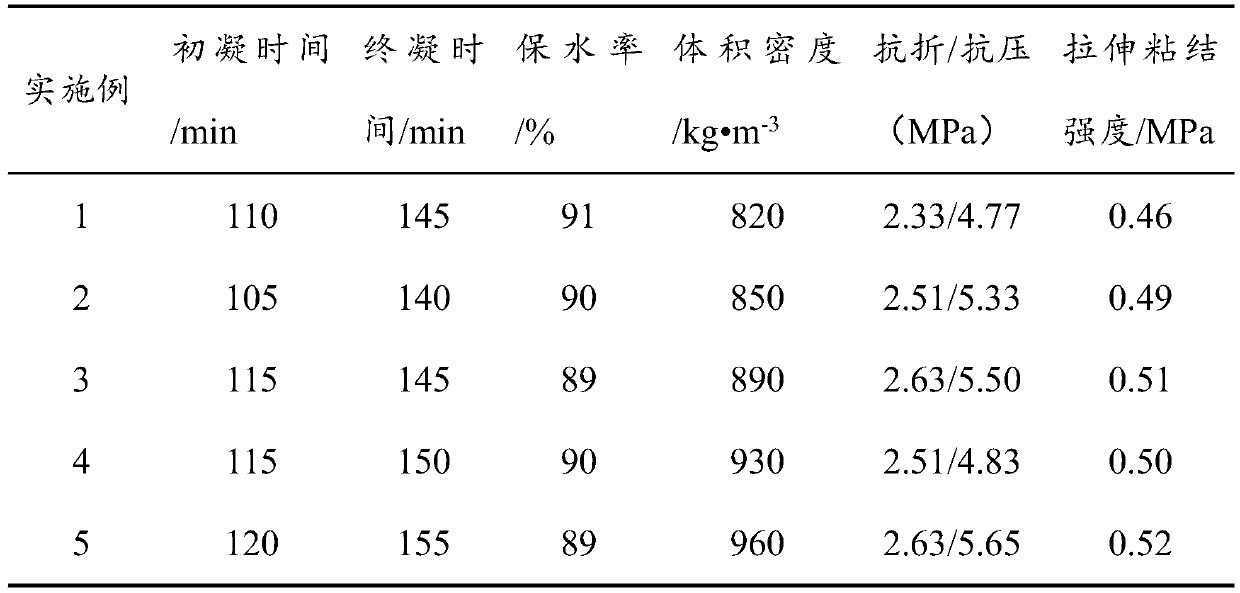

[0044] The machine-sprayed plastering gypsum mortar obtained in the above examples was tested according to various technical perform...

Embodiment 2

[0046] In this embodiment, the preparation of 1 kg of machine-sprayed phosphogypsum lightweight plastering mortar is taken as an example, and the preparation method is as follows.

[0047] Weigh the ingredients according to the prescribed ratio, and the amount of each raw material is:

[0048] 85 parts of phosphogypsum, 5 parts of fine aggregate, 4 parts of inert admixture, 6 parts of vitrified microspheres, 0.08 part of retarder, 0.23 part of water retention agent, 0.04 part of anti-sagging agent (anti-sagging agent), strengthening agent 0.1 part, 0.4 part fiber, 0 part whitening agent.

[0049] Put the above-mentioned raw materials into the mixer in turn and mix them well. After they are fully mixed, the machine-sprayed plaster plaster mortar is obtained. When using, add a small amount of water to adjust and then machine-spray the construction.

[0050] The machine-sprayed plastering gypsum mortar obtained in the above examples was tested according to various technical perfor...

Embodiment 3

[0052] In this embodiment, the preparation of 1 kg of machine-sprayed phosphogypsum lightweight plastering mortar is taken as an example, and the preparation method is as follows.

[0053] Weigh the ingredients according to the prescribed ratio, and the amount of each raw material is:

[0054] 90 parts of phosphogypsum, 5 parts of fine aggregate, 1 part of inert admixture, 4 parts of vitrified microbeads, 0.1 part of retarder, 0.21 part of water retention agent, 0.04 part of anti-sagging agent (anti-sagging agent), strengthening agent 0.1 part, fiber 0.4 part, whitening agent 0.1 part.

[0055] Put the above-mentioned raw materials into the mixer in turn and mix them well. After they are fully mixed, the machine-sprayed plaster plaster mortar is obtained. When using, add a small amount of water to adjust and then machine-spray the construction.

[0056] The machine-sprayed plastering gypsum mortar obtained in the above examples was tested according to various technical perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com