A kind of fiber reinforced mullite ceramic matrix composite material and preparation method thereof

A fiber-reinforced and composite material technology is applied in the field of fiber-reinforced mullite ceramic matrix composite materials and its preparation, which can solve the problems of large preparation cost and cycle, high preparation cost and low solid content of composite materials, and achieves the advantage of low cost , large solid content, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

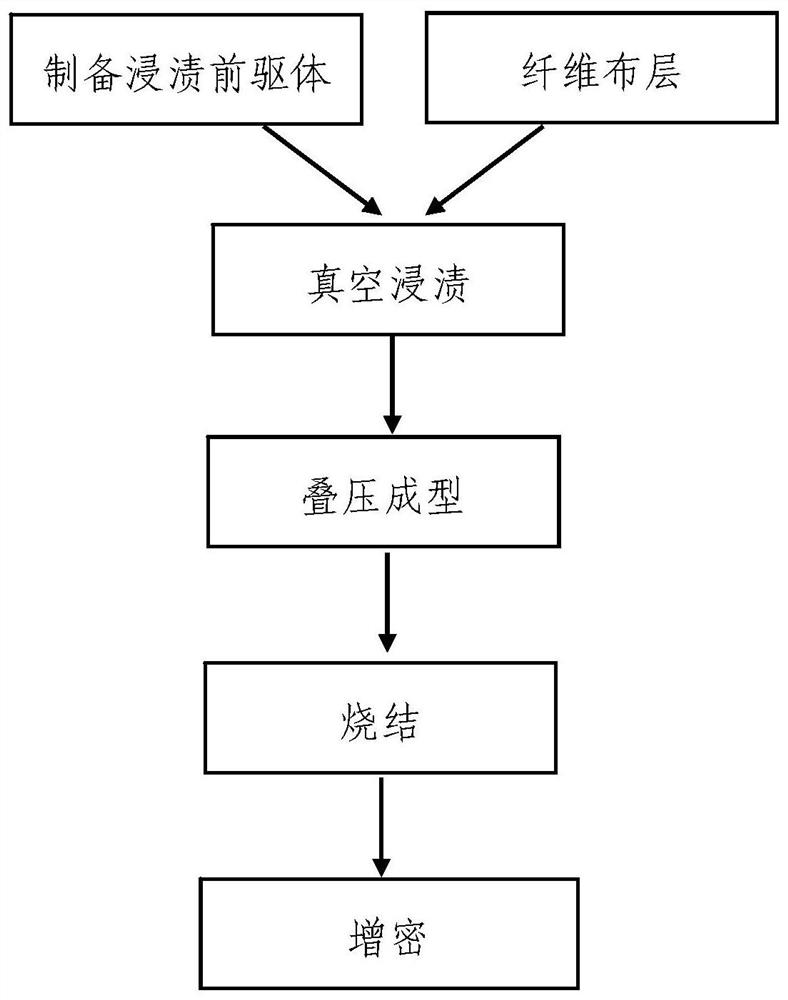

[0034] The present invention provides a method of preparing a fiber reinforced mullite ceramic matrix composite material in a first aspect. The preparation method improves the existing PIP process, thereby making the preparation method with low cost and easy advantages. First, the preparation method provided by the present invention is used to impregnate the silica sol and nano aluminum oxide powder into an impregnated precursor, which has significant low cost compared to single-phase or double phase mockliol. Advantage, and a mixture of solid content (Mullioli is a mixture of silica sol and aluminum sol, and its solid content is generally less than 20 wt%, and the aluminum sol price is higher, but the price of alumina powder is low). Since the ratio of alumina and silicon oxide in the component can be easily regulated, this facilitates the control of the composite matrix components, thereby ensuring a mullite ceramic component. Further, since the impregnation material of such a n...

Embodiment 1

[0069] refer to figure 1First, first, the particle diameter fractionation is less than 100 nm of powder accounts for 80%, 100 nm-200 nm powder accounts for 80%, which is 15% of the oxide powder, which is 15% of the oxide powder, which is 15%, is 15% acidic. In a silica sol, there is a molar ratio of alumina and silicon oxide of 3: 2, and 1% polyethylene glycol is added as a dispersant, passed through the ball milling for 20%, 5 MPa · S and a stable impregnation front drive. body. Then, the alumina fiber cloth layer was placed in a vacuum impregnation apparatus, and after 0.09 MPa evacuated, the slurry injection, the slurry did not fibrous cloth layer, and the vacuum was allowed to be exhausted. Subsequently, the wet cloth layer was taken out from the apparatus, which was superimposed on the plate and dried by a vacuum bag and dried at 0.1 MPa and 40 ° C; secondly, the molded block was sintered at 1000 ° C for 0.5 h. Finally, the fiber reinforcing composite is multi-impregnated-dry...

Embodiment 2

[0071] First, the particle cassette is divided into a powder of 15%, 100 nm to 200 nm, which is 80%, greater than 200 nm, which is more than 200 nm, is dispersed to a solid content of 20% acidic silicon. In the sol, there is a molar ratio of alumina and silicon oxide of 3: 2, and 1% polyethylene glycol is added as a dispersant, and the solid content is 20%, 5 MPa · S and a stable impregnation precursor. . Then, the silicon oxide fiber cloth layer was placed in a vacuum impregnation apparatus, and after 0.09 MPa evacuated, the slurry injection, the slurry did not fibrilize layers, and the vacuum was allowed to be exhausted. Subsequently, the wet cloth layer was taken out from the apparatus, which was superimposed on the plate and dried by a vacuum bag and dried at 0.1 MPa and 40 ° C; secondly, the molded block was sintered at 1000 ° C for 0.5 h. Finally, the fiber reinforcing composite is multi-impregnated-dry-sintering, so that the ceramic density reaches 60% of theoretical densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com