Sandwich structural high-efficiency flame-retardant coating layer with fire warning and super-hydrophobic functions as well as preparation method and application of coating layer

A fire early warning and flame retardant coating technology, applied in the field of flame retardant coatings, can solve the problems of poor water resistance of water-based coatings, low sensitivity of fire early warning systems, inability to apply large-sized materials, etc., and achieve easy control, excellent water resistance and self-cleaning. performance, excellent thermal stability and barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

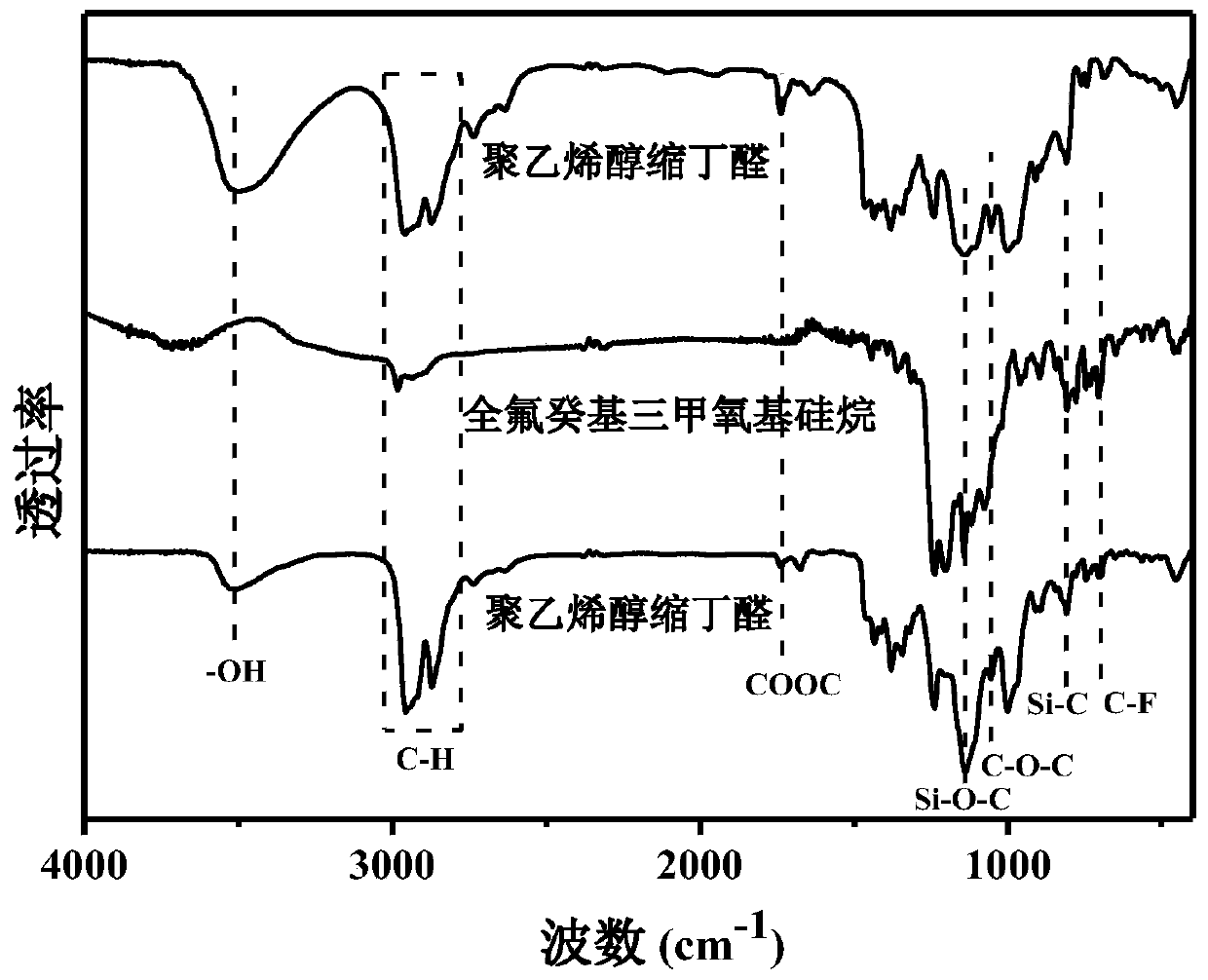

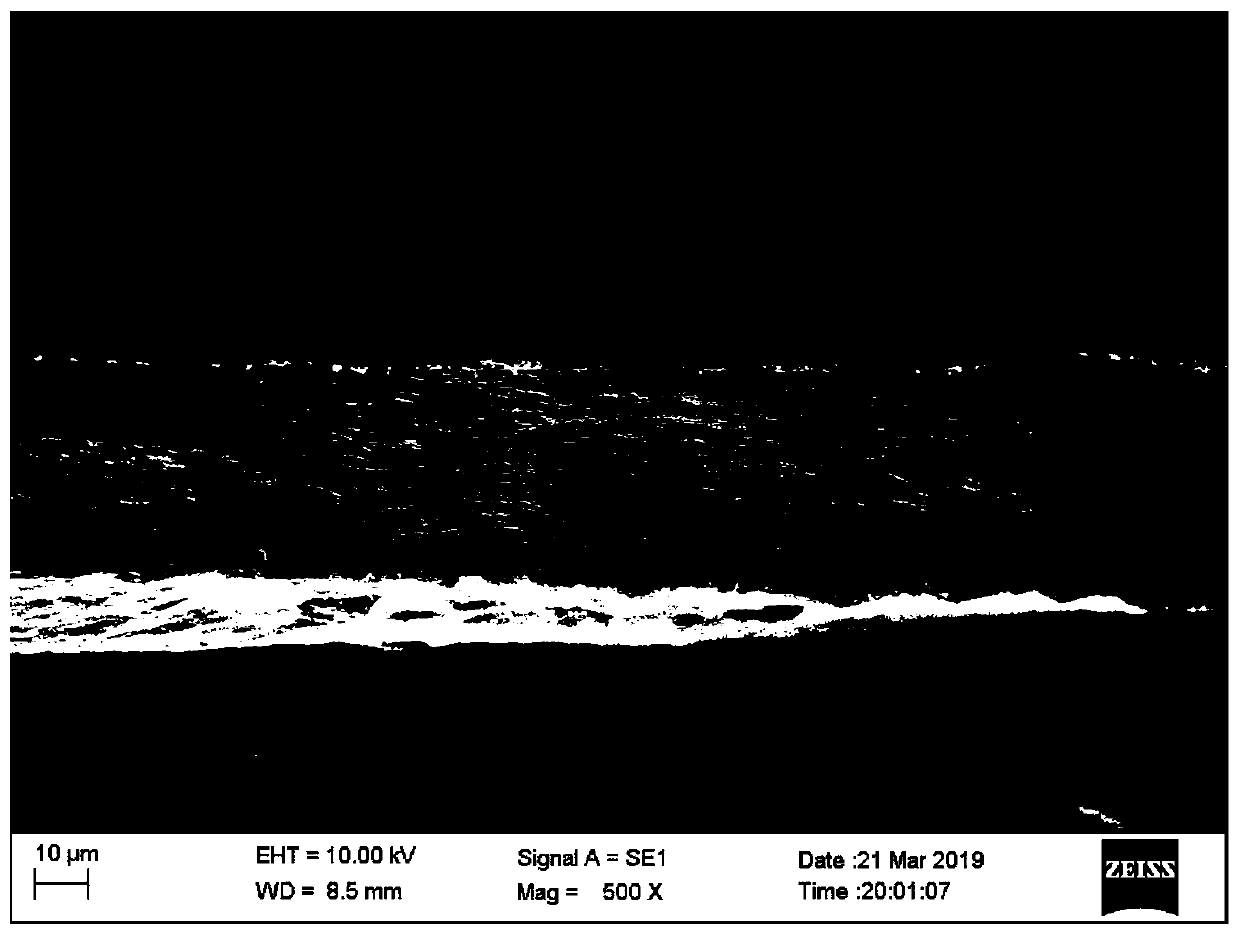

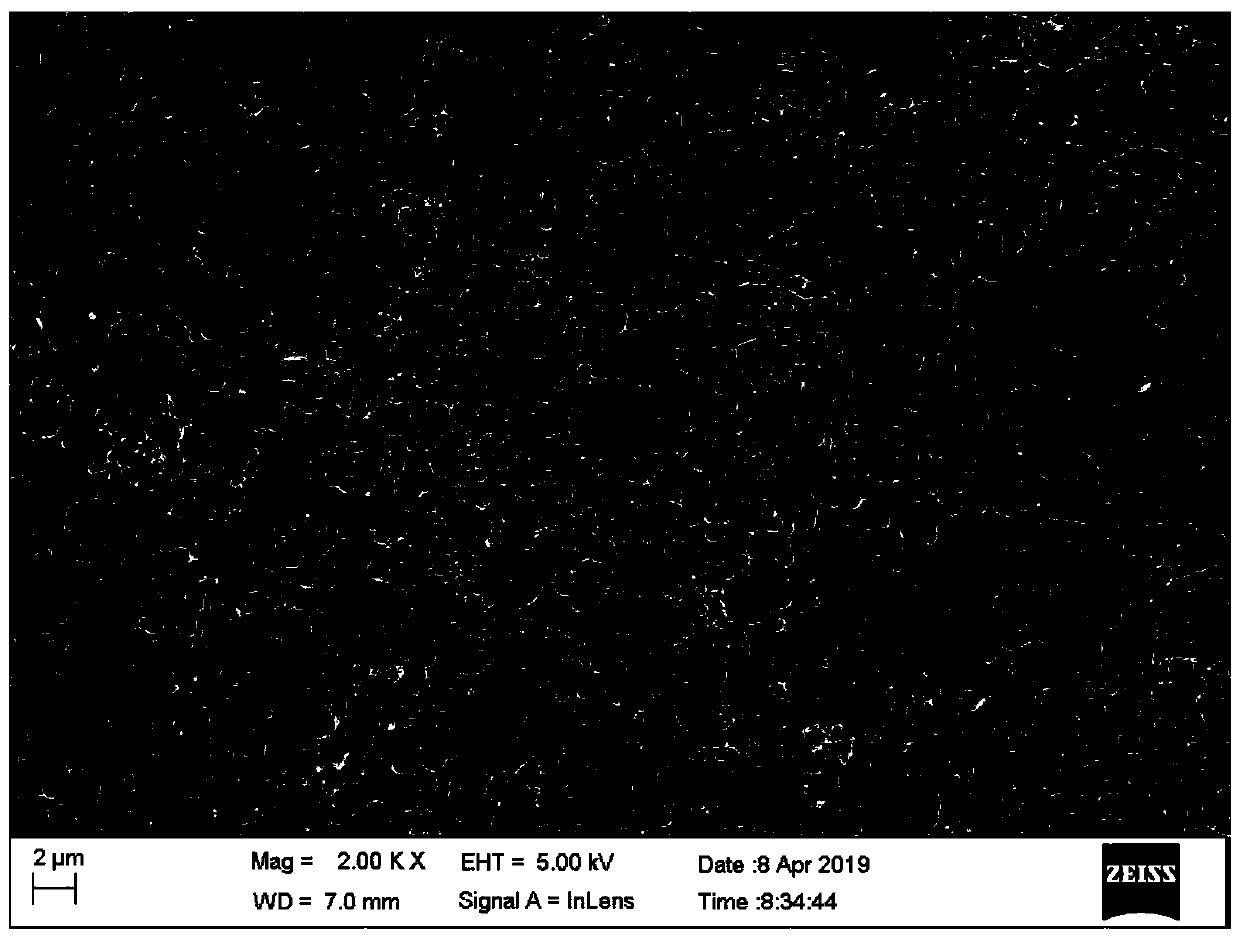

[0035]1) Preparation of the bottom conductive layer: Add 0.8g silver nanowires and 1.2g polyvinyl butyral into 98g ethanol, stir them ultrasonically for 40min to fully disperse them, prepare coating A, and then spray coating A on the polyvinyl butyral On acrylic and sylvestris pine substrates, the coating volume is 0.1mL / cm 2 , and then placed in an oven to dry at 50°C for 10 minutes; the process of spraying and drying was repeated 4 times to obtain a bottom conductive layer with a thickness of about 5 μm;

[0036] 2) Preparation of the temperature-sensitive sensing layer in the middle: add 1g graphene oxide and 1g carboxymethyl chitosan to 98g deionized water together, stir them ultrasonically for 60min to fully disperse them, prepare coating B, and then spray coating B on On the bottom conductive layer prepared in step 1), the coating amount is 0.1mL / cm 2 , and then placed in an oven to dry at 70°C for 30 minutes, and the process of spraying and drying was repeated 10 times...

Embodiment 2

[0042] The difference between this embodiment and Example 1 is: in step 1) and step 3), 0.8g silver nanowires are replaced with 1.2g copper nanowires, the polyvinyl butyral consumption is increased to 2.8g, and the ethanol consumption is reduced to 96g, the ultrasonic stirring time was extended to 60min, and the coating amount was reduced to 0.05mL / cm 2 , the drying temperature was increased to 60°C, and the repetition process was reduced to 2 times. The vertical combustion, fire warning and water resistance test results are shown in Table 1 and Table 2, and the relevant test methods are the same as in Example 1.

Embodiment 3

[0044] The difference between this embodiment and Example 1 is: in step 1) and step 3), 0.8g silver nanowires are replaced with 0.6g silver nanoparticles, the polyvinyl butyral consumption is reduced to 0.4g, and the ethanol consumption is increased to 99g, the ultrasonic stirring time was shortened to 20min, and the repetition process was increased to 6 times. The vertical combustion, fire warning and water resistance test results are shown in Table 1 and Table 2, and the relevant test methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com