Production method of grape polyphenol modified hydrophobic cotton fabric

A technology of grape polyphenols and cotton fabrics, applied in plant fibers, textiles and papermaking, and liquid-repellent fibers, etc., can solve the problems of low durability and limited varieties of super-hydrophobic fabrics, and achieve high contact angles and conditions Mild, broad-spectrum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

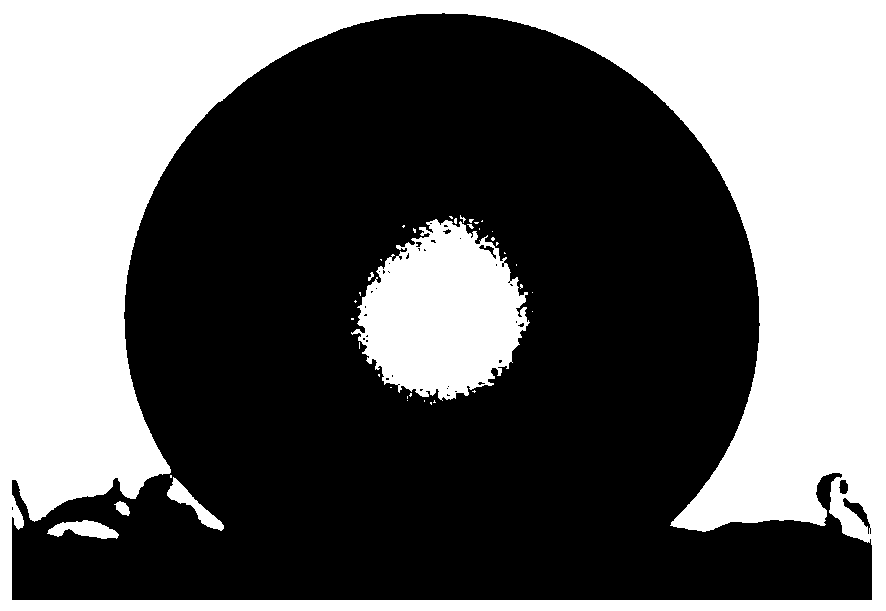

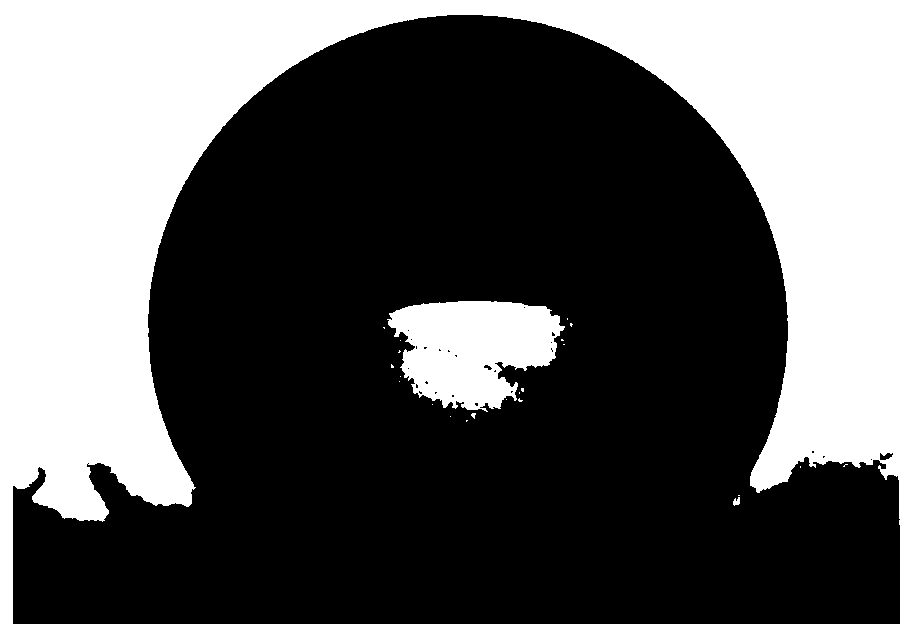

Image

Examples

Embodiment 1

[0031] (1) Wash 1 g of cotton fabric and dry it at 60°C.

[0032] (2) Place 50 mg of grape polyphenols and 25 mg of folic acid weighed in 50 mL of deionized water, mix and stir at 80 degrees Celsius for about 1 hour to obtain a uniform solution, and adjust the pH of the solution with appropriate amount of hydrochloric acid and trishydroxymethylaminomethane was 8.5, and a treatment solution was obtained.

[0033] (3) Immerse the washed and dried cotton fabric obtained in step (1) in a hydrogen peroxide solution with a bath ratio of 1:30, the concentration of hydrogen peroxide is 2mL / L, and the Adjust the pH value to 9, the temperature to 85°C, and the treatment time to be 10 minutes;

[0034] (4) Take out the activated cotton fabric, add it to the reaction solution prepared in step (2) with a bath ratio of 1:30, and react at 70°C and pH 8.5 for 2 hours;

[0035] (5) Measure 70mL of absolute ethanol and 30mL of deionized water and mix them in a beaker, weigh 0.1617g of octadec...

Embodiment 2

[0042] (1) Wash 2g of cotton fabric and dry it at 50°C.

[0043] (2) Put the weighed 100mg of grape polyphenols and 70mg of folic acid in 100mL of deionized water, mix and stir at 50 degrees Celsius, and obtain a uniform solution after about 90 minutes, and adjust the solution with appropriate amount of hydrochloric acid and trishydroxymethylaminomethane The pH was 8.5, and a treatment liquid was obtained.

[0044] (3) Immerse the washed and dried cotton fabric obtained in step (1) in a hydrogen peroxide solution with a bath ratio of 1:30, the concentration of hydrogen peroxide is 3mL / L, and the Adjust the pH value to 8.5, the temperature is 80°C, and the treatment time is 13 minutes;

[0045] (4) Take out the activated cotton fabric, add it to the reaction solution prepared in step (2) with a bath ratio of 1:40, and react at 75°C and pH 9 for 2.5 hours;

[0046] (5) Take 70mL of absolute ethanol and 30mL of deionized water and mix them in a beaker, weigh 0.2156g of octadecyla...

Embodiment 3

[0050] (1) Wash 1 g of cotton fabric and dry it at 50°C.

[0051] (2) Place 75mg of grape polyphenols and 40mg of folic acid weighed in 50mL of deionized water, mix and stir at 50 degrees Celsius for about 90 minutes to obtain a prepared uniform solution, and adjust the pH of the solution with appropriate amount of hydrochloric acid and trishydroxymethylaminomethane was 8.5, and a treatment solution was obtained.

[0052] (3) Immerse the washed and dried cotton fabric obtained in step (1) in a hydrogen peroxide solution with a bath ratio of 1:30, the concentration of hydrogen peroxide is 4mL / L, and the Adjust the pH value to 8.2, the temperature is 75°C, and the treatment time is 9 minutes;

[0053] (4) Take out the activated cotton fabric, add it to the reaction solution prepared in step (2) with a bath ratio of 1:20, and react at 70°C and pH 8.1 for 1.8 hours;

[0054] (5) Measure 70mL of absolute ethanol and 30mL of deionized water and mix them in a beaker, weigh 0.1886g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com