Method for recovering electrolyte in waste lithium ion battery

A lithium-ion battery and recycling method technology, which is applied in the field of recycling and processing waste lithium-ion battery electrolyte, can solve problems such as air pollution, fluorine does not meet environmental protection standards, and high operating costs, and achieves the effect of improving separation rate and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Recycling and processing of electrolyte in the waste lithium-ion battery of embodiment 1

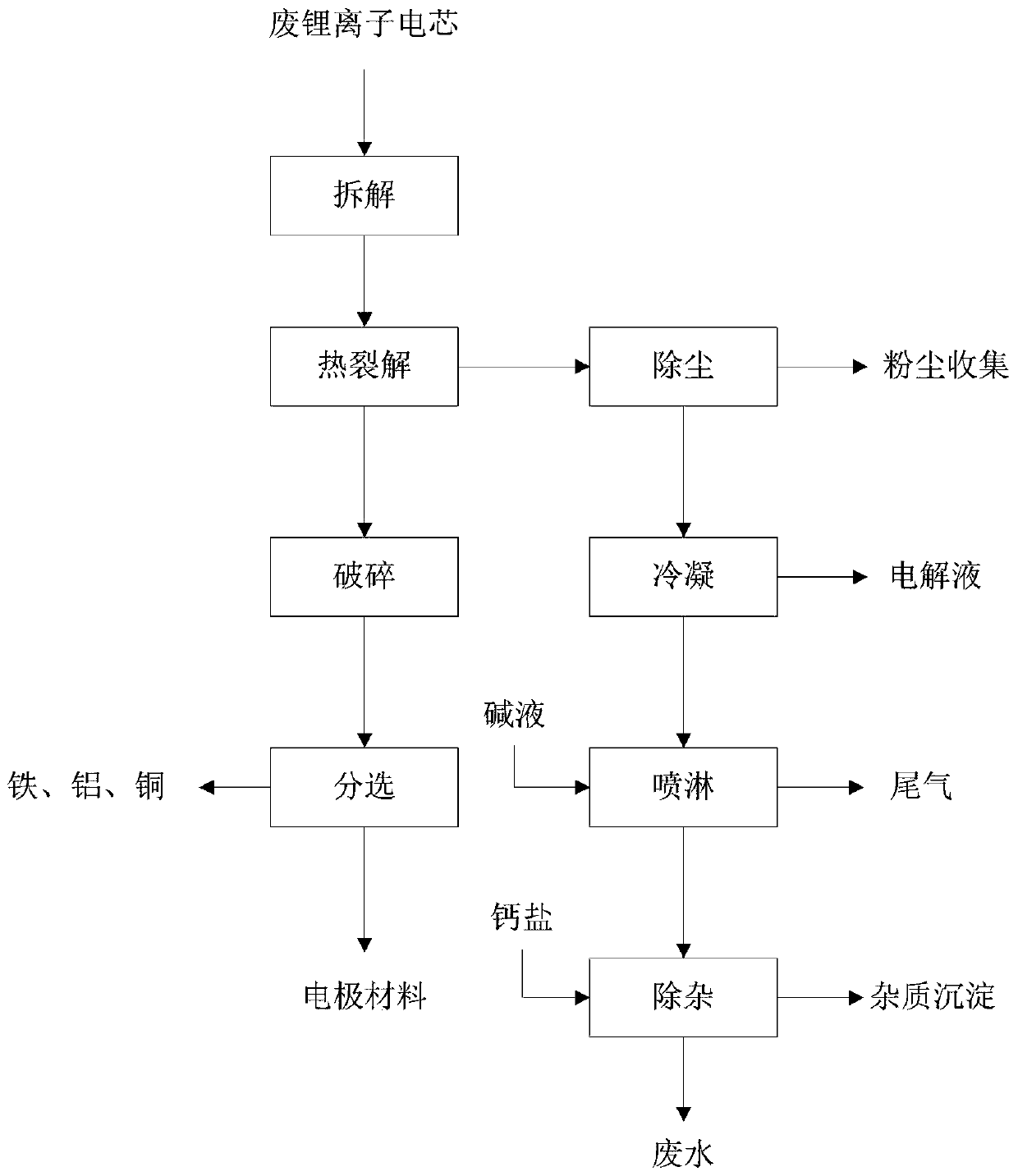

[0029] process such as figure 1 shown.

[0030] The specific process is as follows:

[0031] 1. Disassemble the discharged waste lithium-ion single cells by mechanical means, destroy the internal structure of the battery, facilitate transportation, improve processing efficiency, and avoid risks. Single cells include pouch batteries, cylindrical batteries, and square batteries.

[0032] 2. The disassembled cell material is subjected to thermal cracking treatment, which can effectively solve the pollution of electrolyte and binder. Electrolyte LiPF in the electrolyte 6 It is converted into fluoride and phosphide, and the solvent is vaporized; the binder is carbonized into amorphous carbon to fail, and the separation rate of the electrode material and the current collector is improved. The pyrolysis temperature is 400°C, the pyrolysis time is about 1.0h, and the pyrolysis proces...

Embodiment 2

[0037] Embodiment 2 Recycling and processing of electrolyte in waste lithium-ion batteries

[0038] process such as figure 1 shown.

[0039] The specific process is as follows:

[0040] 1. Disassemble the discharged waste lithium-ion single cells by mechanical means, destroy the internal structure of the battery, facilitate transportation, improve processing efficiency, and avoid risks. Single cells include pouch batteries, cylindrical batteries, and square batteries.

[0041] 2. The disassembled cell material is subjected to thermal cracking treatment, which can effectively solve the pollution of electrolyte and binder. Electrolyte LiPF in the electrolyte 6 It is converted into fluoride and phosphide, and the solvent is vaporized; the binder is carbonized into amorphous carbon to fail, and the separation rate of the electrode material and the current collector is improved. The pyrolysis temperature is 300°C, and the pyrolysis time is about 1.5h. Pass inert gas protectio...

Embodiment 3

[0045] Embodiment 3 Recycling of Electrolyte in Waste Lithium-ion Batteries

[0046] process such as figure 1 shown.

[0047] The specific process is as follows:

[0048] 1. Disassemble the discharged waste lithium-ion single cells by mechanical means, destroy the internal structure of the battery, facilitate transportation, improve processing efficiency, and avoid risks. Single cells include pouch batteries, cylindrical batteries, and square batteries.

[0049] 2. The disassembled cell material is subjected to thermal cracking treatment, which can effectively solve the pollution of electrolyte and binder. Electrolyte LiPF in the electrolyte 6 It is converted into fluoride and phosphide, and the solvent is vaporized; the binder is carbonized into amorphous carbon to fail, and the separation rate of the electrode material and the current collector is improved. The pyrolysis temperature is about 500°C, the pyrolysis time is about 0.5, and the pyrolysis process is protected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com