Ceramic electric heating body with two-layer structure and electric soldering iron

A technology of electric heating body and layer structure, applied in the direction of soldering iron, electric heating device, ohmic resistance heating, etc., can solve the problems of affecting electronic components, inaccurate welding, large impact current, etc., and achieve low process difficulty, reliable structure, and reduced diameter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

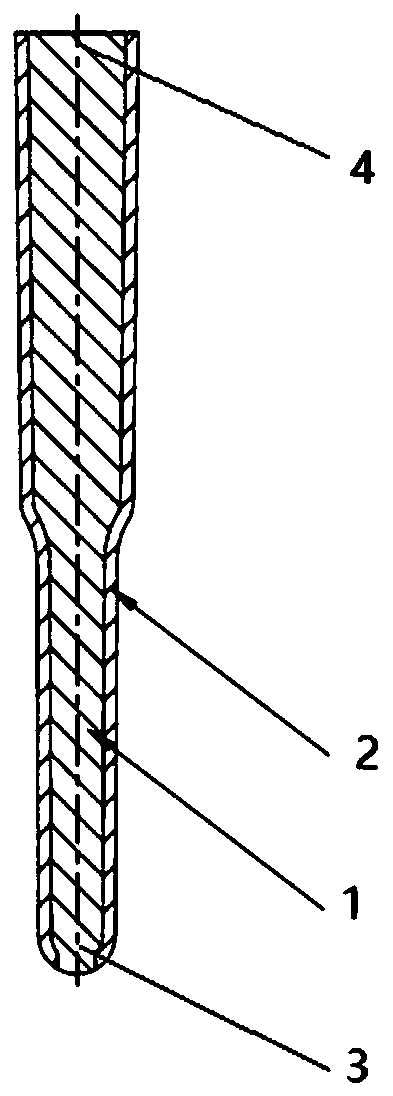

[0040] Embodiment 1: as figure 2 and 4 As shown, a two-layer structure ceramic electric heating body, the electric heating body includes a conductive layer 1 and an outer insulating layer 2; the insulating layer is wrapped outside the conductive layer, and the head 3 of the electric heating body and the conductive layer at the tail part 4 are exposed outside the insulating layer. And the conductive layer and the insulating layer at the tail of the ceramic heating element in this embodiment are flush. Through the technical solution of this embodiment, a two-layer all-ceramic heating element with a diameter of less than 1 mm can be obtained.

[0041] The two-layer structure ceramic heating element in this embodiment can be used as a thermocouple. Weld the central electrode 7 at the conductive layer at its tail. The central electrode can be used as a thermocouple, or the central electrode can be used as one pole of the thermocouple, and the metal material or its extension ma...

Embodiment 2

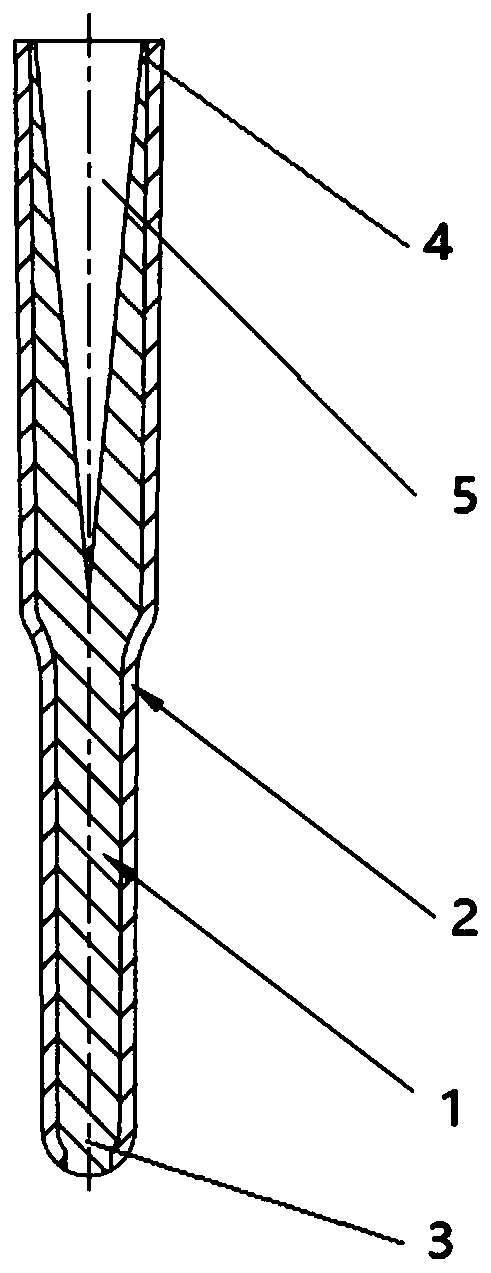

[0074] Embodiment 2: as image 3 and 5 As shown, this embodiment is a modification made on the basis of Embodiment 1.

[0075] In this embodiment, the electric heating body includes an inner conductive layer 1 and an outer insulating layer 2; The conductive layer is exposed outside the insulating layer. And the conductive layer at the tail of the ceramic heating element in this embodiment is provided with grooves or blind holes. Square grooves, circular grooves, polygonal grooves, circular blind holes, tapered blind holes, V-shaped blind holes, etc. can be set. In this embodiment, a V-shaped blind hole 5 is provided at the tail of the conductive layer. Through the technical solution of this embodiment, a two-layer all-ceramic heating element with a diameter of less than 1 mm can be obtained.

[0076] For the all-ceramic heating element with the above two-layer structure, the central electrode can be welded in the V-shaped blind hole of the conductive layer at the tail, th...

Embodiment 3

[0082] Embodiment 3: as Image 6 and 7 As shown, in this embodiment, the ceramic heating element in Embodiment 1 or Embodiment 2 is applied to small heating parts such as electric soldering irons.

[0083] Two layers of ceramic electric heaters are used to produce embryos, and the metallized coating is coated on the head, and the material of the metallized coating is silver copper + titanium.

[0084] And as one of the embodiments, the ceramic electric heater in this embodiment is divided into a front section near the head and a rear section near the tail, and the diameter of the front section is smaller than that of the rear section.

[0085] The electric soldering iron includes a soldering iron tip 11, one end of the soldering iron tip is a working end, and the other end is provided with a blind hole. Insert the front part of the ceramic heating element 10 into the blind hole, so that the metallized head of the ceramic heating element is in contact with the tip of the sold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com