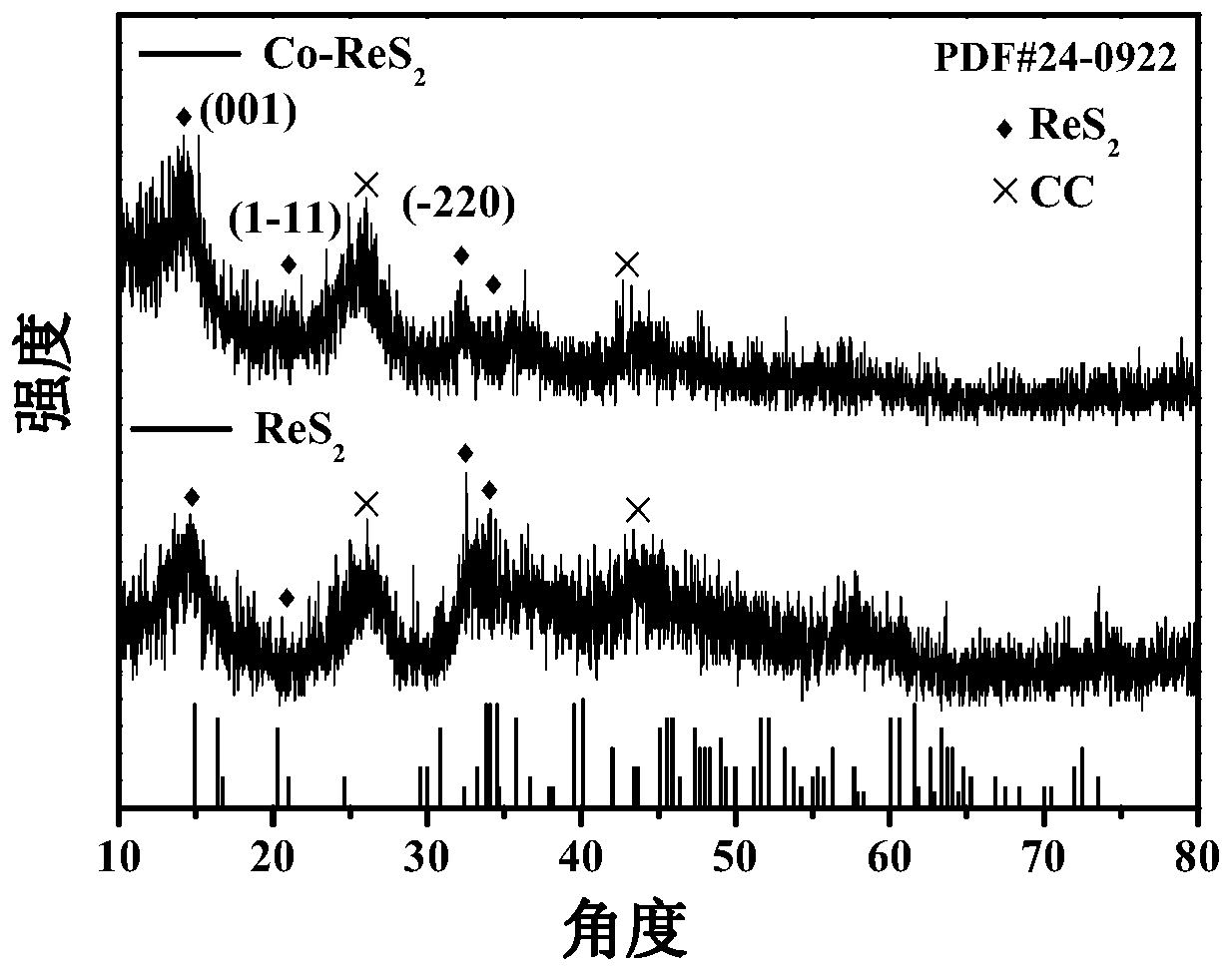

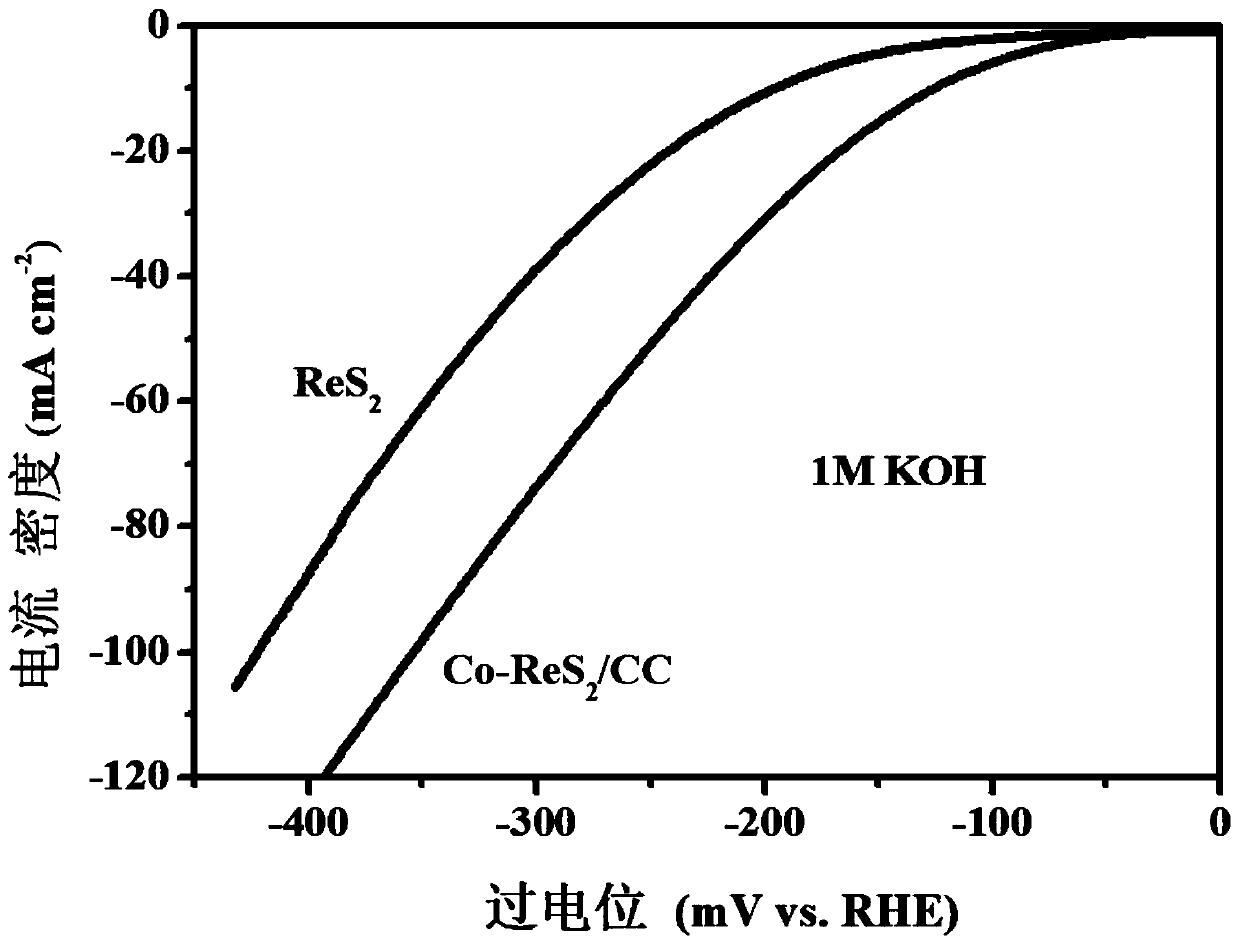

Preparation method of cobalt-doped rhenium disulfide nanosheet array for electro-catalytic hydrogen evolution

A nanosheet array and rhenium disulfide technology, applied in the field of electrocatalysis, can solve the problems of difficult directional growth of rhenium disulfide nanosheets, reduced electrocatalytic hydrogen evolution reaction activity, and high potential energy consumption, so as to improve the performance of electrocatalytic hydrogen evolution, Improve the hydrogen evolution reaction activity and enhance the effect of electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 0.291g of 2-methylimidazole dissolved in 40ml of water and stir for 10min to form A solution, weigh 1.3136g of cobalt nitrate hexahydrate dissolved in 40ml of water and stir for 10min to form B solution, then quickly add A solution into B solution and stir for 30min A mixed C solution was obtained. Put a piece of nitric acid treated carbon cloth (WOS109 type, 1*1.5*0.036cm 3 ) into the C solution. After reacting for 4 hours, samples were taken, washed repeatedly with deionized water, and then grown in the same solution for another 4 hours. Finally, the sample was washed with deionized water, dried under vacuum at 60°C overnight, and a layer of purple sample (ZIF-67 / CC) was loaded on black carbon cloth.

[0021] Weigh 0.5g of cobalt nitrate hexahydrate and dissolve it in 40ml of a mixed solution of ultrapure water and ethanol with a volume ratio of 1:9, put the previously prepared ZIF-67 / CC into it, stir at room temperature for 30min, and take out the sample , w...

Embodiment 2

[0024] Weigh 0.407g of 2-methylimidazole dissolved in 40ml of water and stir for 10min to form A solution, weigh 1.3136g of cobalt nitrate hexahydrate dissolved in 40ml of water and stir for 10min to form B solution, then quickly add A solution into B solution and stir for 30min A mixed C solution was obtained. Put a piece of nitric acid treated carbon cloth (WOS109 type, 1*1.5*0.036cm 3 ) into the C solution. After reacting for 4 hours, samples were taken, washed repeatedly with deionized water, and then grown in the same solution for another 4 hours. Finally, the sample was washed with deionized water, dried under vacuum at 60°C overnight, and a layer of purple sample (ZIF-67 / CC) was loaded on black carbon cloth.

[0025] Weigh 0.5g of cobalt nitrate hexahydrate and dissolve it in 40ml of a mixed solution of ultrapure water and ethanol with a volume ratio of 1:9, put the previously prepared ZIF-67 / CC into it, stir at room temperature for 30min, and take out the sample , w...

Embodiment 3

[0028] Weigh 0.52g of 2-methylimidazole dissolved in 40ml of water and stir for 10min to form A solution, weigh 1.3g of cobalt nitrate hexahydrate dissolved in 40ml of water and stir for 10min to form B solution, then quickly add A solution into B solution and stir for 30min A mixed C solution was obtained. Put a piece of nitric acid treated carbon cloth (WOS109 type, 1*1.5*0.036cm 3 ) into the C solution. After reacting for 4 hours, samples were taken, washed repeatedly with deionized water, and then grown in the same solution for another 4 hours. Finally, the sample was washed with deionized water, dried under vacuum at 60°C overnight, and a layer of purple sample (ZIF-67 / CC) was loaded on black carbon cloth.

[0029] Weigh 0.5g of cobalt nitrate hexahydrate and dissolve it in 40ml of a mixed solution of ultrapure water and ethanol with a volume ratio of 1:9, put the previously prepared ZIF-67 / CC into it, stir at room temperature for 30min, and take out the sample , washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com