Transition metal phosphorus sulfide active phase preparation method

A technology of transition metals and phosphorus sulfides, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as safety problems, and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of Ni by In Situ Temperature Programmed Reduction (TPR) of Phosphate Precursor 2 P, MoP and WP catalysts.

[0022] Weigh 6.60g nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and 3.00g diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) were dissolved in 10mL and 15mL of deionized water respectively, under the condition of magnetic stirring, the (NH 4 ) 2 HPO 4 The solution was slowly added Ni(NO 3 ) 2 ·6H 2 In the O solution, after the dropwise addition, continue to stir for 0.5h, quickly evaporate a large amount of water, continue drying at 120°C for 12h, and then roast at 500°C for 3h to obtain Ni 2 P phosphate precursor with a Ni / P molar ratio of 1.

[0023] Weigh 4.01g ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 3.00g diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) were dissolved in 10mL and 15mL of deionized water respectively, under the condition of magnetic stirring, the (NH 4 ) 2 HPO 4 The solution was slowly added drop...

Embodiment 2

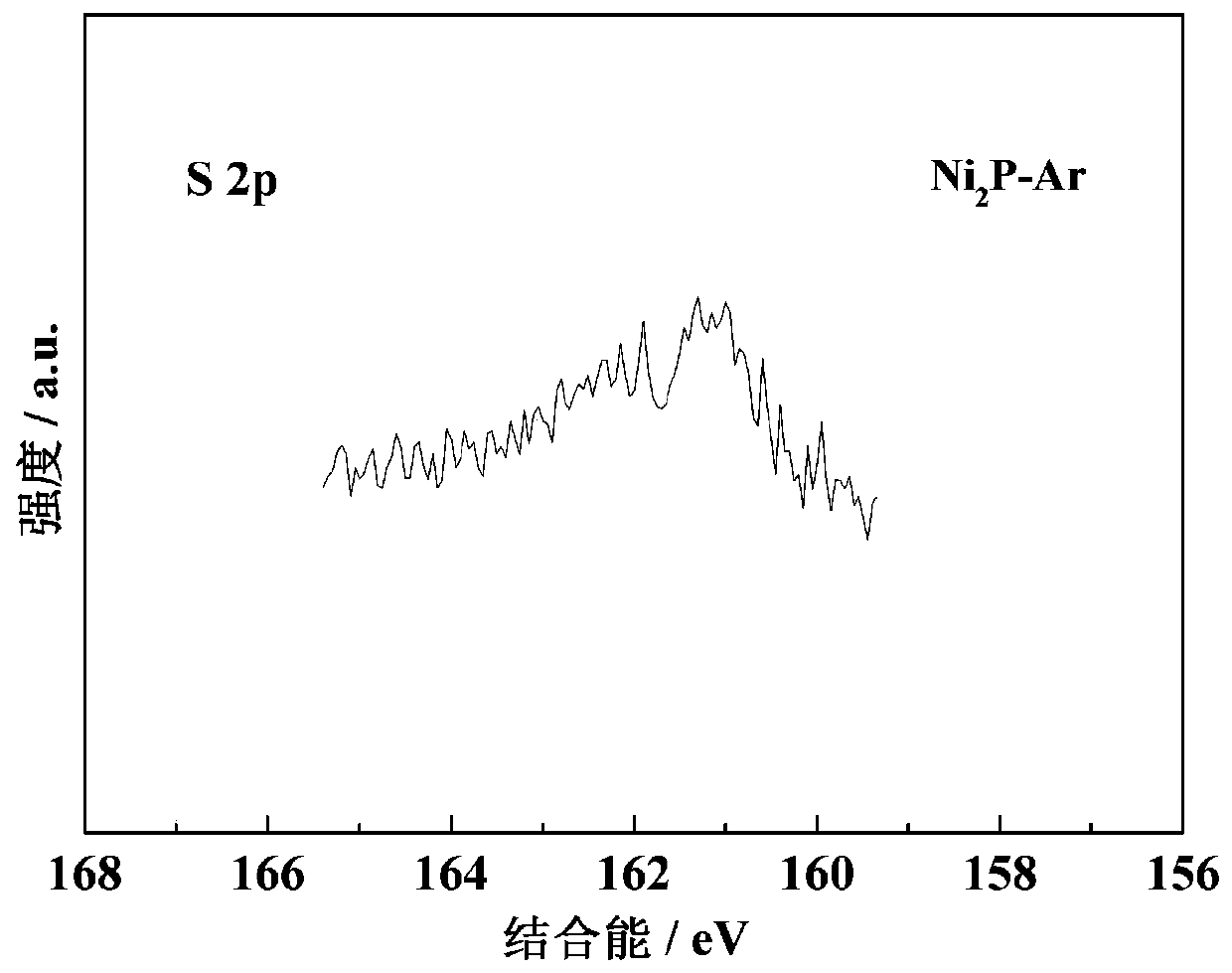

[0027] According to the method described in Example 1, in-situ reduction prepares Ni 2 After the P catalyst, lower the temperature to 240°C, and pass through the vulcanizing agent to react and vulcanize. The vulcanization liquid raw material used is 1.25% (mass fraction) of 2-phenyl-cyclohexanethiol / decalin solution, and the vulcanization conditions are: Ar pressure 4MPa, Ar flow rate 75mL / min, temperature 240°C, liquid hourly space velocity 54h -1 , The vulcanization treatment time is 2h. XPS spectrum of S2p region ( figure 1 ) shows that S is successfully embedded on the surface of the catalyst, and according to the position of the characteristic peak, the main sulfur species is S δ- (02 Phosphorus sulfide active phase of P.

Embodiment 3

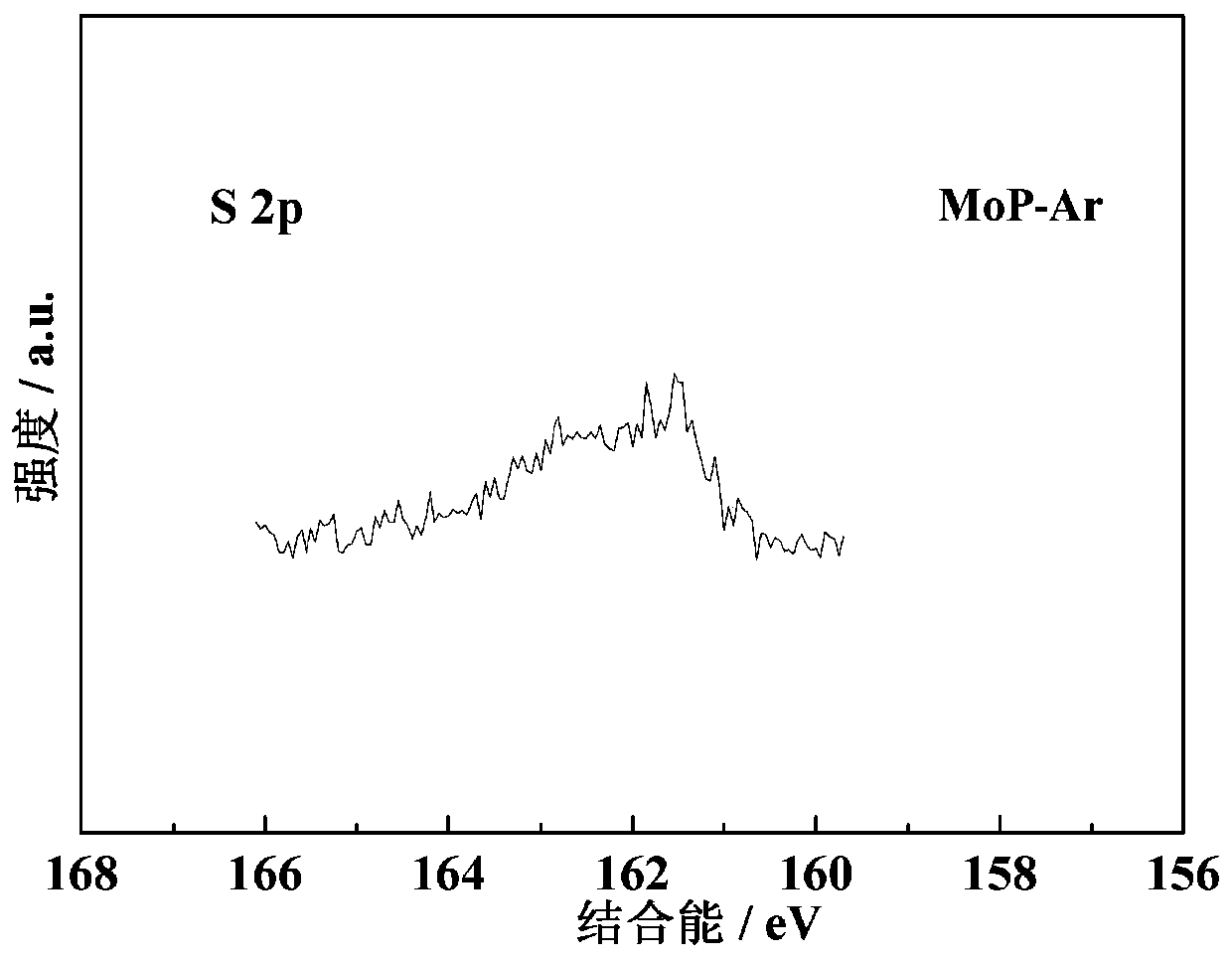

[0029] According to the method described in Example 1, after the MoP catalyst was prepared by in-situ reduction, the temperature was lowered to 240° C., and a vulcanizing agent was introduced to react and vulcanize. The vulcanization liquid raw material used is 1.25% (mass fraction) 2-phenyl-cyclohexanethiol (2-PCHT) / decalin solution, and the vulcanization conditions are: Ar pressure 4MPa, Ar flow rate is 75mL / min, temperature 240 ℃, liquid hourly space velocity 54h -1 , The vulcanization treatment time is 2h. S 2p region XPS spectrum ( figure 2 ) shows that: 2-PCHT can successfully sulfide the surface of MoP in an inert atmosphere to form the phosphorus sulfide active phase of MoP. According to the characteristic peak position, the main sulfur species is S δ- (0<δ≤2). The sulfur content (in atomic percent) was 11.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com