Production method and application of iron-nitrogen co-doped carbon catalyst used for electrocatalytic reduction of CO2

A carbon-based catalyst and co-doping technology, applied in the field of electrocatalysis, can solve the problem of difficult activation of carbon materials and achieve the effect of increasing the degree of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

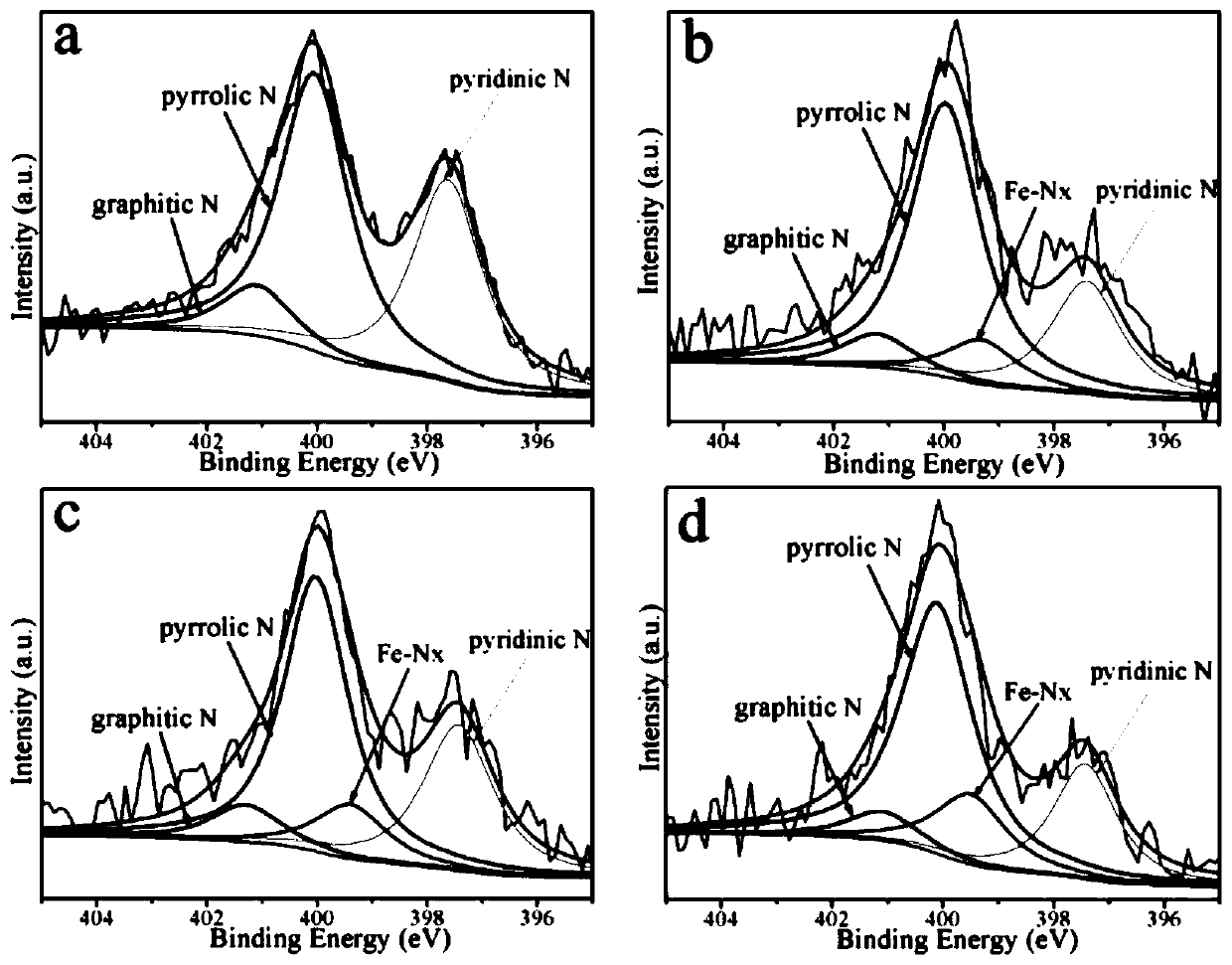

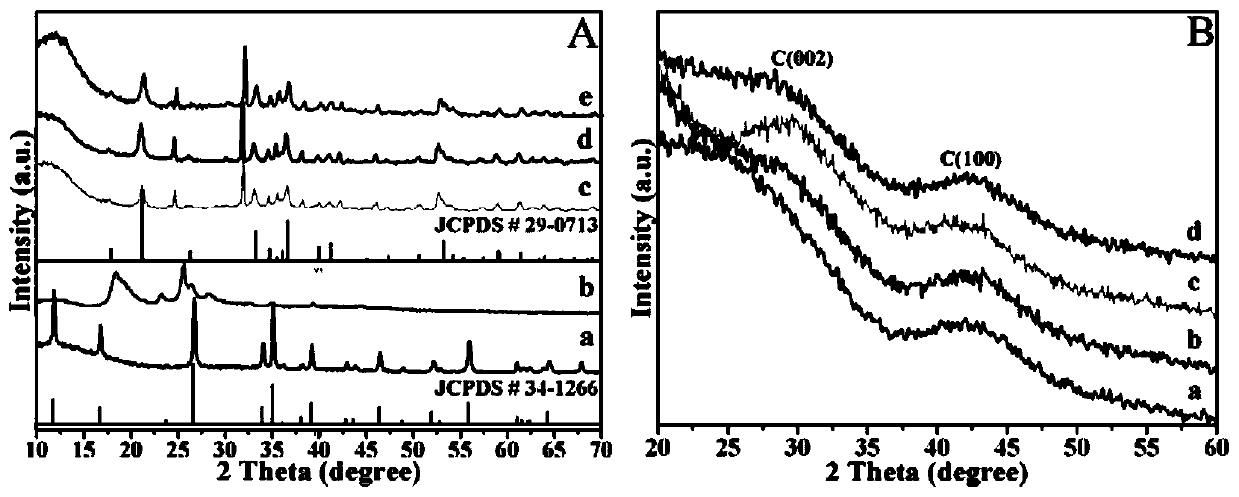

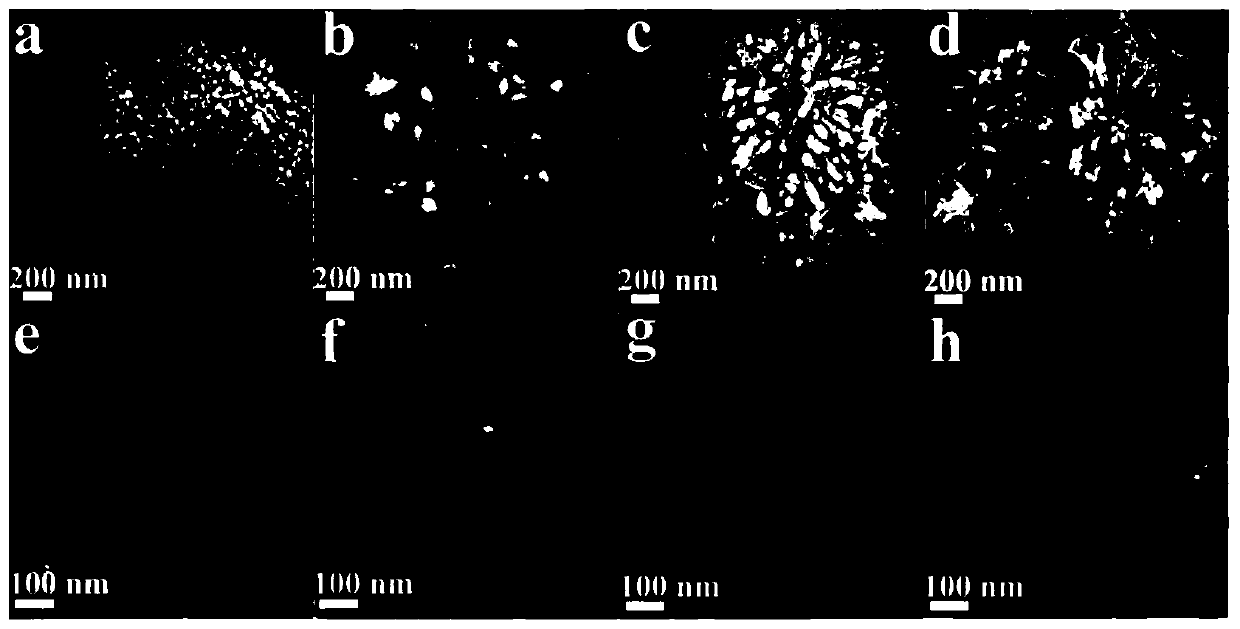

[0025] Electrocatalytic reduction of CO in this example 2 The preparation method of the iron-nitrogen co-doped carbon catalyst, the steps are as follows:

[0026] (1) Dissolve 2.7029 g ferric chloride hexahydrate and 3.03 g urea in 120 ml deionized water, stir for 0.5 h to fully dissolve; add 0.4 ml aniline, stir for 1 h; add, then add 0.9128 g APS, stir for 0.5 h; put the solution in an autoclave and react at 120°C for 4 hours; after the reaction is completed, the product is washed with deionized water and anhydrous ethanol in turn to neutrality, and placed in a 60°C oven after completion , and dried for 12 h to obtain the precursor FeOOH / PANI-0.4.

[0027] (2) Put the FeOOH / PANI-0.4 precursor into a tube furnace, N 2 environment, at 5℃·min -1 The Fe / N-C sample was heated to 800 °C at a rate of 100 °C, kept at this temperature for 2 h, and then naturally cooled to room temperature to obtain the Fe / N-C sample; the Fe / N-C sample was pickled at 80 °C in a 2M aqueous sulfuric ...

Embodiment 2

[0029] Electrocatalytic reduction of CO in this example 2 The preparation method of the iron-nitrogen co-doped carbon catalyst, the steps are as follows:

[0030] (1) Dissolve 2.7029 g ferric chloride hexahydrate and 3.03 g urea in 120 ml deionized water, stir for 0.5 h to fully dissolve; add 0.5 ml aniline, stir for 1 h; then add 1.141 g APS, stir for 0.5 h; The solution was placed in an autoclave and reacted at 120 °C for 4 h; after the reaction was completed, the product was washed with deionized water and anhydrous ethanol in turn until neutral, and then placed in a 60 °C oven for drying. After 12 h, the precursor FeOOH / PANI-0.5 was obtained.

[0031] (2) Put FeOOH / PANI-0.5 precursor into a tube furnace, N 2 environment, at 5℃·min -1The temperature was raised to 800°C at a high rate, and kept at this temperature for 2h, and then cooled down to room temperature naturally to obtain the sample Fe / N-C; the Fe / N-C sample was acid-washed in 2M sulfuric acid aqueous solution a...

Embodiment 3

[0033] The present embodiment is used for electrocatalytic reduction of CO 2 The preparation method of the iron-nitrogen co-doped carbon catalyst, the steps are as follows:

[0034] (1) Dissolve 2.7029 g ferric chloride hexahydrate and 3.03 g urea in 120 ml deionized water, stir for 0.5 h to fully dissolve; add 0.6 ml aniline, stir for 1 h; then add 1.369 g APS, stir for 0.5 h; Place the solution in a high-pressure reactor and react at 120°C for 4 h; after the reaction is complete, wash the product with deionized water and absolute ethanol in turn until neutral, then put it in an oven at 60°C and dry it After 12 h, the precursor FeOOH / PANI-0.6 was obtained.

[0035] (2) Put the FeOOH / PANI-0.6 precursor into the tube furnace, N 2 Under ambient conditions, at 5°C·min -1 The temperature was raised to 800°C at a high rate, and kept at this temperature for 2h, and then cooled down to room temperature naturally to obtain the sample Fe / N-C; the Fe / N-C sample was acid-washed in 2M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com