Method for removing harmful elements of wet-process phosphoric acid and derivative products thereof and equipment

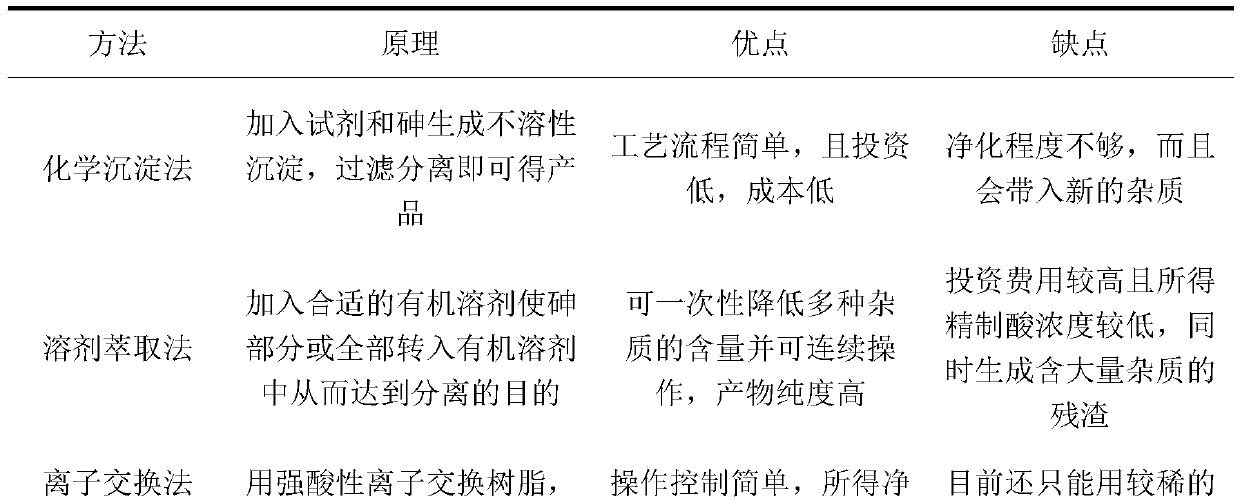

A wet-process phosphoric acid, harmful element technology, applied in non-metallic elements, chemical instruments and methods, fluorosilicic acid, etc., can solve the problem of arsenic removal research or industrial experiments that are rarely reported, and reduce raw material consumption, reduce Visual pollution, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

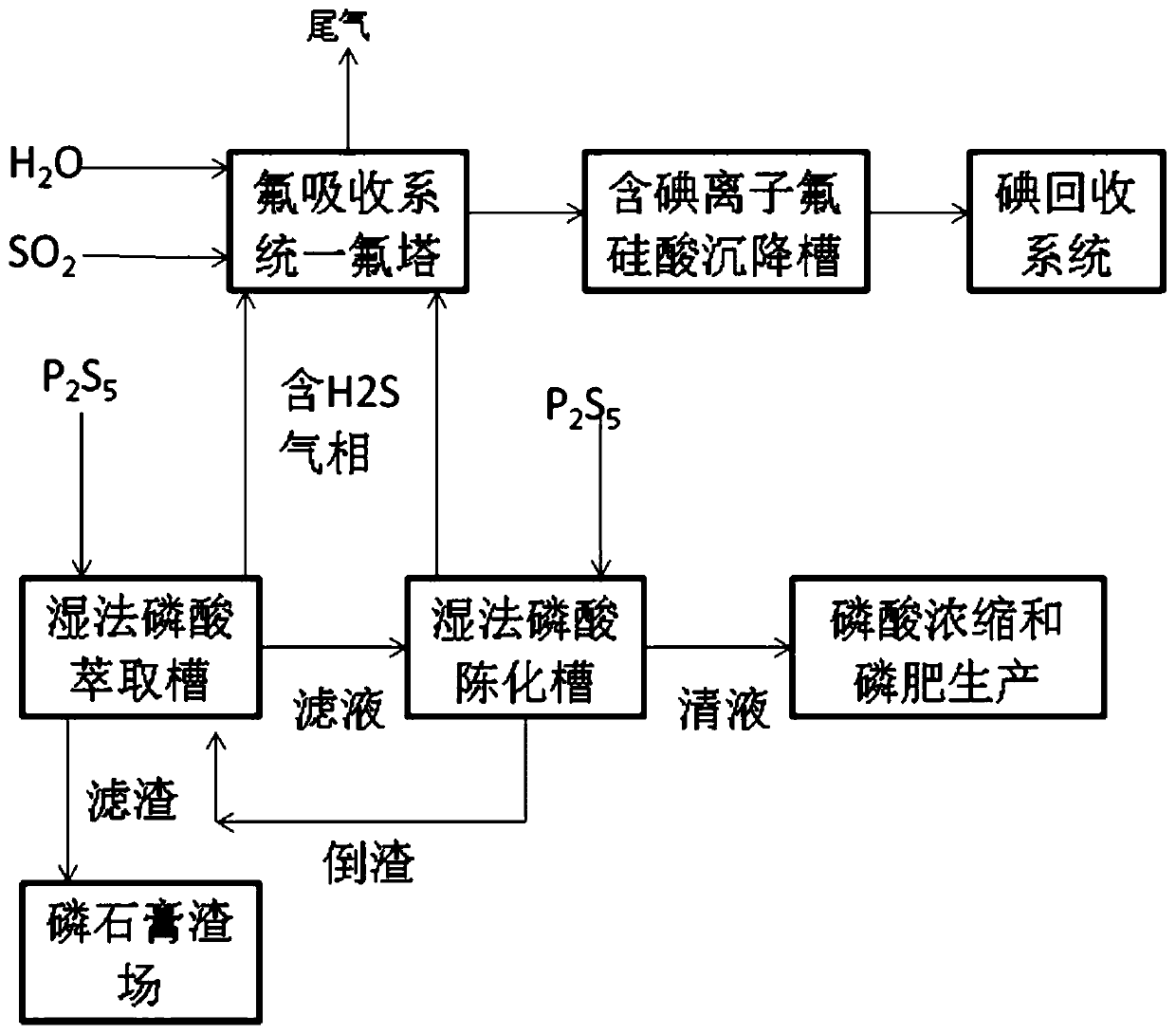

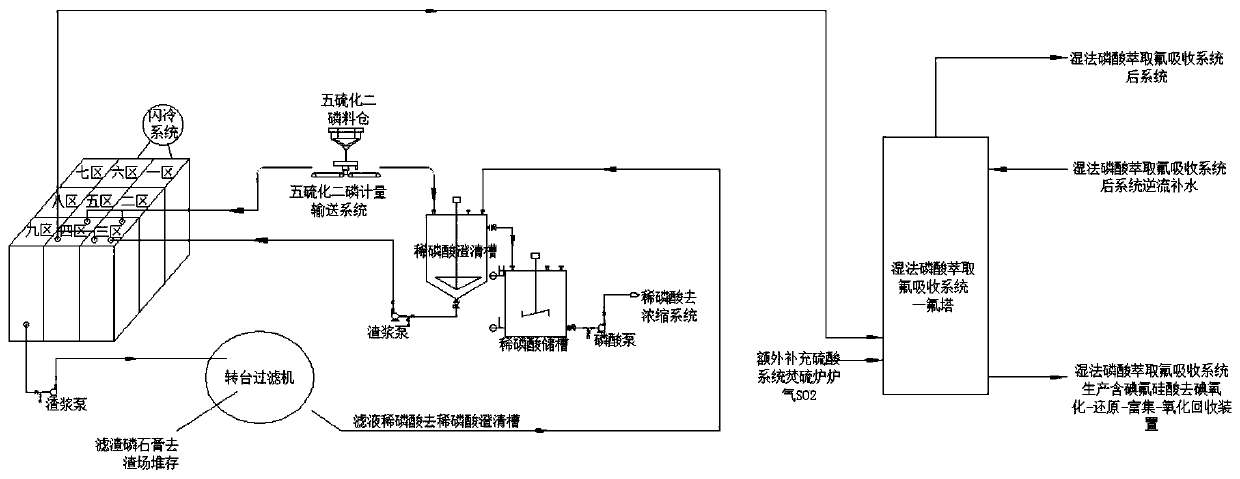

[0065] (1) Use the assembled equipment for processing, add a sufficient amount of phosphorus pentasulfide to the wet-process phosphoric acid extraction tank, and filter it with a three-stage countercurrent washing rotary filter after fully reacting. In the phosphogypsum slag field, the filtrate is transferred to the wet-process phosphoric acid aging tank to collect the gas released during the reaction;

[0066] (2) Add phosphorus pentasulfide to the wet-process phosphoric acid aging tank, filter after fully reacting, filter residue turns back to the wet-process phosphoric acid extraction tank and proceeds to step (1), the filtrate is used for phosphoric acid concentration and phosphate fertilizer production, collects escaped in the reaction process gas;

[0067] (3) Dissolve the gas collected in steps (1), (2) in water, add SO 2 Configured for a concentration of 6% SO 2 Aqueous solution, add 30% H with a volume fraction of 1.75% to iodine-containing dilute phosphoric acid an...

Embodiment 2

[0070] (1) Use the assembled equipment for processing, add a sufficient amount of phosphorus pentasulfide to the wet-process phosphoric acid extraction tank, and filter it with a three-stage countercurrent washing rotary filter after fully reacting. In the phosphogypsum slag field, the filtrate is transferred to the wet-process phosphoric acid aging tank to collect the gas released during the reaction;

[0071] (2) Add phosphorus pentasulfide to the wet-process phosphoric acid aging tank, filter after fully reacting, and the filter residue turns back to the wet-process phosphoric acid extraction tank to continue step (1), and the filtrate is used for phosphoric acid concentration and phosphate fertilizer production. gas;

[0072] (3) Dissolve the gas collected in steps (1), (2) in water, add SO 2 configured for a concentration of 2% SO 2 Aqueous solution, add 30% H with a volume fraction of 0.5% to iodine-containing dilute phosphoric acid and fluosilicic acid 2 o 2 Oxidant...

Embodiment 3

[0075] (1) Use the assembled equipment for processing, add a sufficient amount of phosphorus pentasulfide to the wet-process phosphoric acid extraction tank, and filter it with a three-stage countercurrent washing rotary filter after fully reacting. In the phosphogypsum slag field, the filtrate is transferred to the wet-process phosphoric acid aging tank to collect the gas released during the reaction;

[0076] (2) Add phosphorus pentasulfide to the wet-process phosphoric acid aging tank, filter after fully reacting, and the filter residue turns back to the wet-process phosphoric acid extraction tank to continue step (1), and the filtrate is used for phosphoric acid concentration and phosphate fertilizer production. gas;

[0077] (3) Dissolve the gas collected in steps (1), (2) in water, add SO 2 Configured as 10% SO 2 Aqueous solution, add 30% H with a volume fraction of 3.0% to iodine-containing dilute phosphoric acid and fluosilicic acid 2 o 2 Oxidant, the reaction temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com