Wood-plastic composite material with high strength and biological durability and preparation method thereof

A wood-plastic composite material and modification technology, applied in the field of composite materials and wood-plastic composite materials, can solve the problems of high cost of plastics and products easily eroded by fungi, improve mechanical strength, improve anti-fungal erosion effect, and improve interface associative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

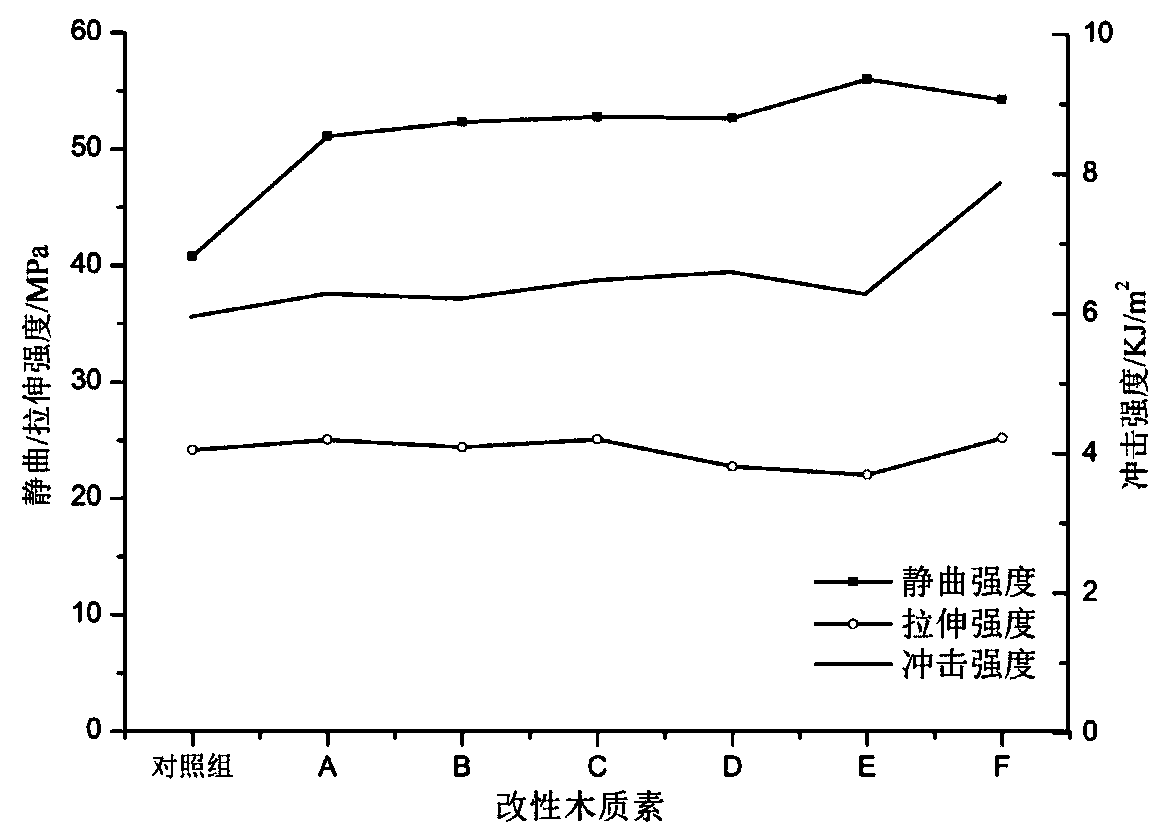

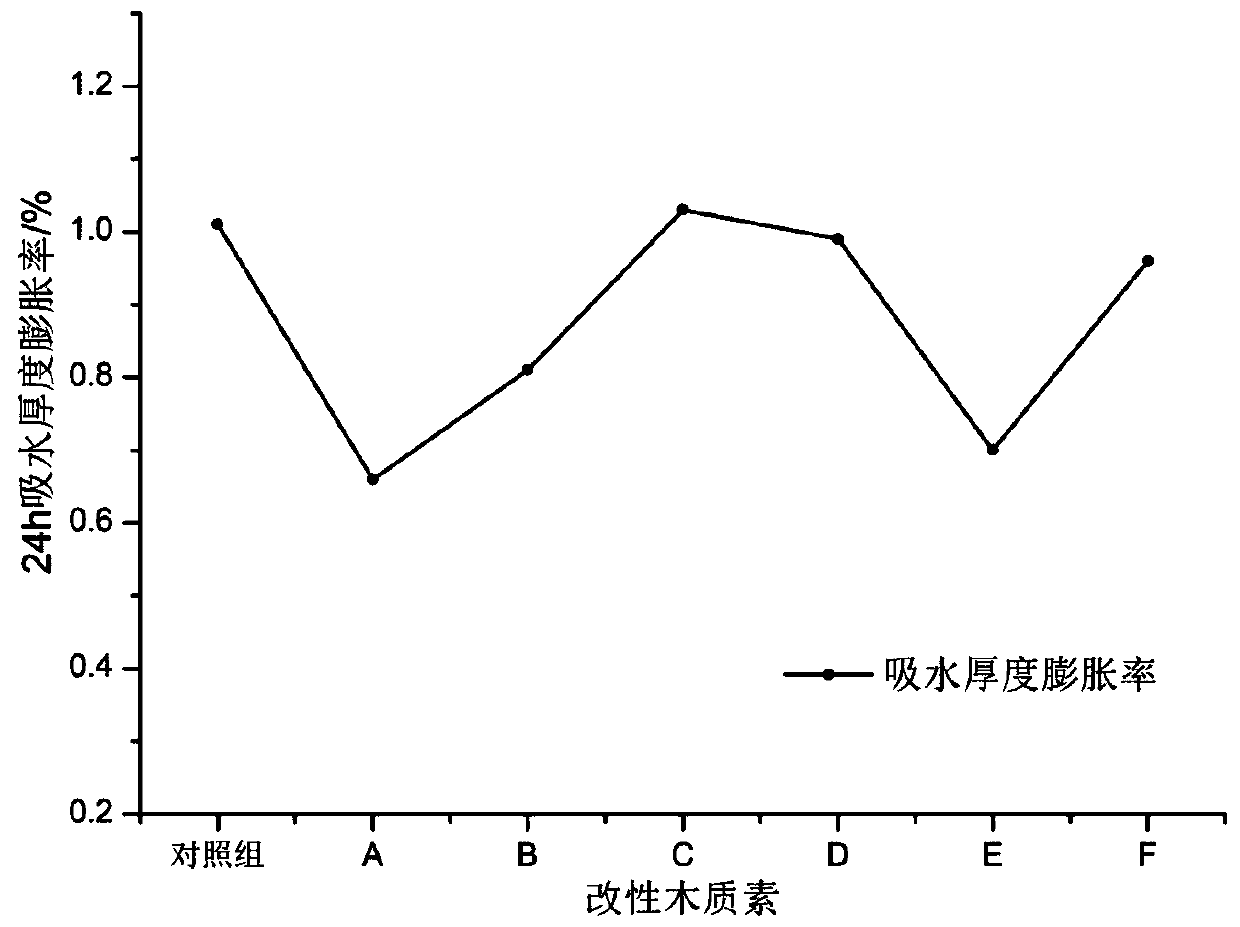

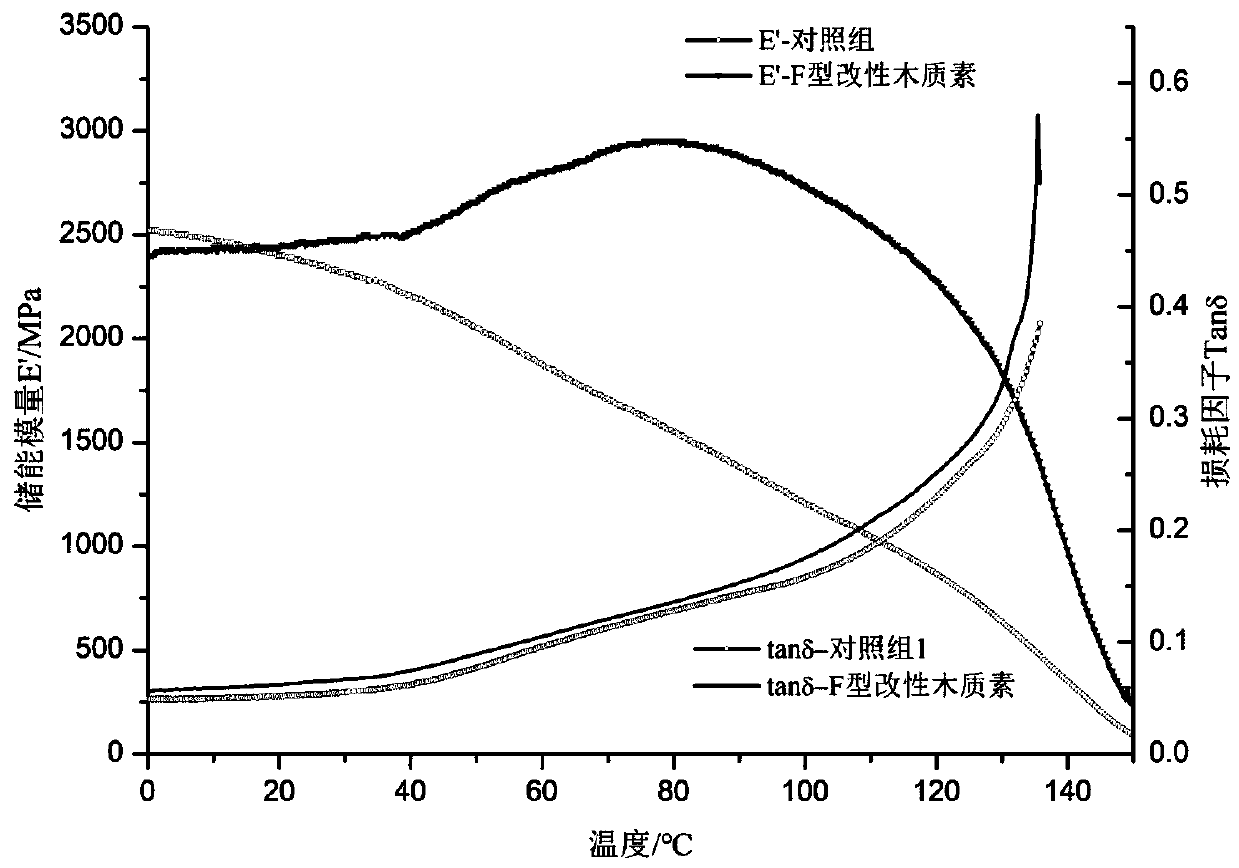

Examples

Embodiment 1

[0037] The lignin modification method of the present embodiment is carried out as follows:

[0038] Lignin modification: Dissolve lignin in 1mol / L sodium hydroxide solution, adjust the pH of the solution to 11, heat in a water bath, and add 37% formaldehyde after reaching a reaction temperature of 80°C. The mass ratio of lignin to formaldehyde is 2: 1. After reacting for 2 hours, cool to room temperature, adjust the pH value of the solution to 2 with 12% hydrochloric acid, centrifuge the precipitated modified lignin, rinse with distilled water, and dry in a blast dryer at 50°C to obtain modified lignin .

[0039] The preparation method of the wood-plastic composite material of the present embodiment comprises the following steps:

[0040] Drying: Dry the modified lignin at 50°C for 24 hours, and dry the wood powder at 102°C for 4 hours;

[0041] Mixture: 10% modified lignin; 50% wood flour; 20% density 0.93g / cm 3 polyethylene; the content of 10% compatibilizer, the compatib...

Embodiment 2

[0045] The lignin modification method of the present embodiment is carried out as follows:

[0046] Dissolve lignin in 1mol / L sodium hydroxide solution, adjust the pH of the solution to 11, heat in a water bath, and add 37% formaldehyde after reaching a reaction temperature of 90°C. The mass ratio of lignin to formaldehyde is 3:1, and react for 2 hours. Cool to room temperature, adjust the pH value of the solution to 2 with 12% hydrochloric acid, then centrifuge the precipitated modified lignin, rinse with distilled water, and dry in a blast dryer at 50°C to obtain modified lignin.

[0047] The preparation method of the wood-plastic composite material of the present embodiment comprises the following steps:

[0048] Drying: Dry the modified lignin at 50°C for 24 hours, and dry the wood powder at 105°C for 4 hours;

[0049] Mixture: 10% modified lignin; 50% wood flour; 25% density 0.90g / cm 3 The polyethylene; compatibilizer, filler, lubricant and dispersant are mixed in a hig...

Embodiment 3

[0054] The lignin modification method of the present embodiment is carried out as follows:

[0055] Dissolve lignin in 1mol / L sodium hydroxide solution, adjust the pH of the solution to 11, heat in a water bath, and add 37% formaldehyde after reaching the reaction temperature of 90°C. The mass ratio of lignin to formaldehyde is 3:1, and react for 3 hours. Cool to room temperature, adjust the pH value of the solution to 3 with 12% hydrochloric acid, then centrifuge the precipitated modified lignin, wash it with distilled water, and dry it in a blast dryer at 60°C to obtain modified lignin.

[0056] The preparation method of the wood-plastic composite material of the present embodiment comprises the following steps:

[0057] Drying: Dry the modified lignin at 60°C for 24 hours, and dry the wood powder at 105°C for 4 hours;

[0058] Mixture: the content of modified lignin is 15%; the content of wood powder is 45%; the density is 0.96g / cm 3 The polyethylene content is 25%; the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com