Electronic equipment, display screen, and glass cover plate and manufacturing method thereof

A technology for electronic equipment and glass cover, applied in the field of electronic equipment, can solve problems such as affecting liquid crystal orientation, dirt adsorption, black screen, etc., and achieve the effects of improving performance, reducing dirt adsorption, and preventing black screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

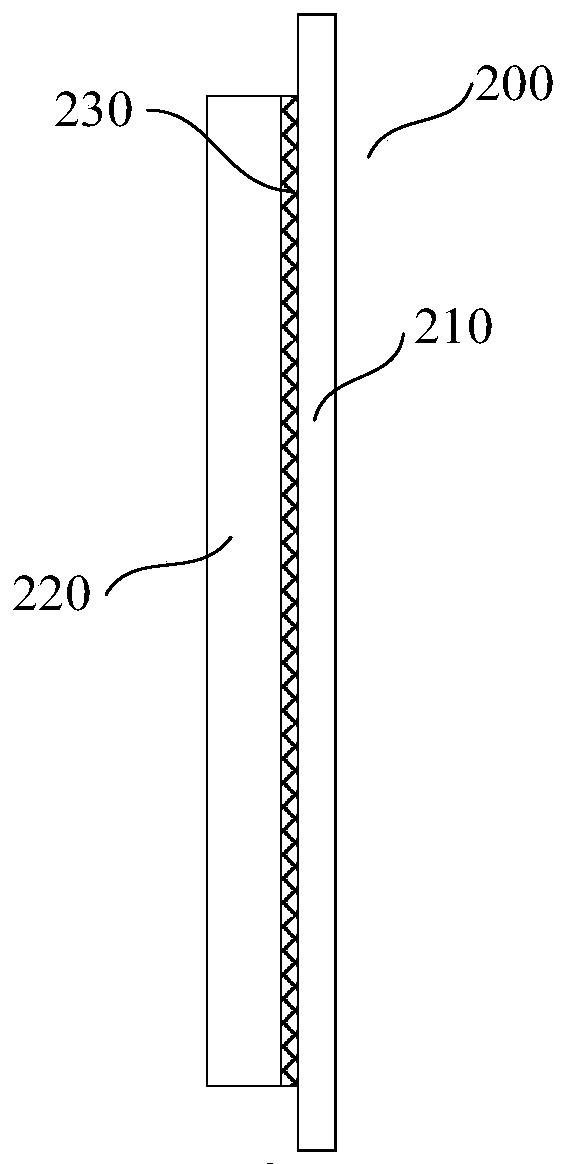

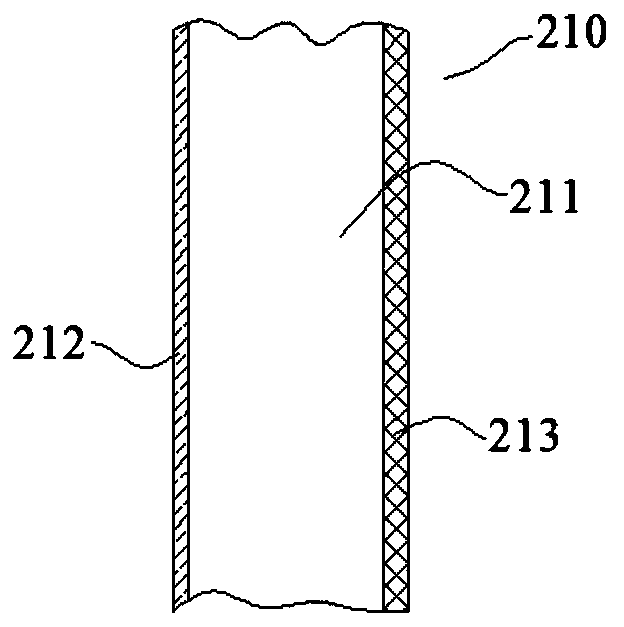

[0205] The present application also provides a method 600 for preparing a glass cover for a display screen, please refer to Figure 11 , Figure 11 A schematic diagram of a method 600 for preparing a glass cover for a display screen is shown, through which the aforementioned method 600 can be obtained Figure 4-6 Referring to the cover glass 210, the method 600 includes:

[0206] Step 610, obtaining the glass substrate and antistatic ink;

[0207] Step 620, disposing the antistatic ink on the back of the glass substrate and curing it to form an antistatic ink layer, the surface resistance of the antistatic ink layer is 1.0×10 5 ~1.0×10 12 ohm.

[0208] Specifically, in step 610, first obtain the glass substrate and antistatic ink, for example, the glass substrate can be obtained through the following methods: Glass processing: through sweeping, 3D hot bending, 3D heat absorption, welding, CNC, laser engraving, cutting Processes such as processing glass raw materials into ...

Embodiment a

[0230] According to the size and outline of the glass cover of the electronic device display, the glass substrate is selected and cut into a glass substrate of the corresponding size, and the glass substrate of the corresponding outline is formed by 3D hot bending, and then the glass substrate is placed in NaNO 3 with KNO 3 Perform chemical strengthening treatment in molten salt to obtain a chemically strengthened glass substrate, which is used for the next step by cleaning and drying;

[0231] 2g conductive carbon black was ultrasonically dispersed in 30ml isoamyl acetate to obtain antistatic solution A;

[0232] Add 1 g of pigment carbon black to 30 g of acrylic resin with a solid content of 50% (parts by weight) (the solvent is a 1:1 mixture of toluene / butyl acetate), and mechanically stir to obtain resin B;

[0233] Mix antistatic solution A and resin B evenly, add 0.5g vinyl triamine curing agent, obtain carbon black / acrylic resin antistatic ink for use;

[0234] Place ...

Embodiment b

[0240] According to the size and outline of the glass cover of the electronic device display, the glass substrate is selected and cut into a glass substrate of the corresponding size, and the glass substrate of the corresponding outline is formed by 3D hot bending, and then the glass substrate is placed in NaNO 3 with KNO 3 Perform chemical strengthening treatment in molten salt to obtain a chemically strengthened glass substrate, which is used for the next step by cleaning and drying;

[0241] Ultrasonic dispersion of 1.8g conductive graphite filler in 25ml isobutyl acetate to obtain antistatic solution A;

[0242] Add 1.5g of pigment carbon black to 30g of epoxy resin with a solid content of 50% (parts by weight) (solvent is propylene glycol methyl ether acetate / ethylene glycol ether / ethanol 2:1:1 mixture), mechanically stir to obtain resin B ;

[0243] Mix antistatic solution A and resin B evenly, add 0.8g of N-aminoethylpiperazine curing agent, and obtain graphite / epoxy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com