Smelting system for separating and enriching vanadium and producing pure iron from iron ore concentrate

A technology for separating, enriching, and iron concentrate is applied in the field of smelting systems for separating and enriching vanadium and producing pure iron, which can solve the problems of low vanadium recovery rate, low added value, and complex molten iron composition, and achieves improved vanadium recovery rate, The effect of low production cost and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

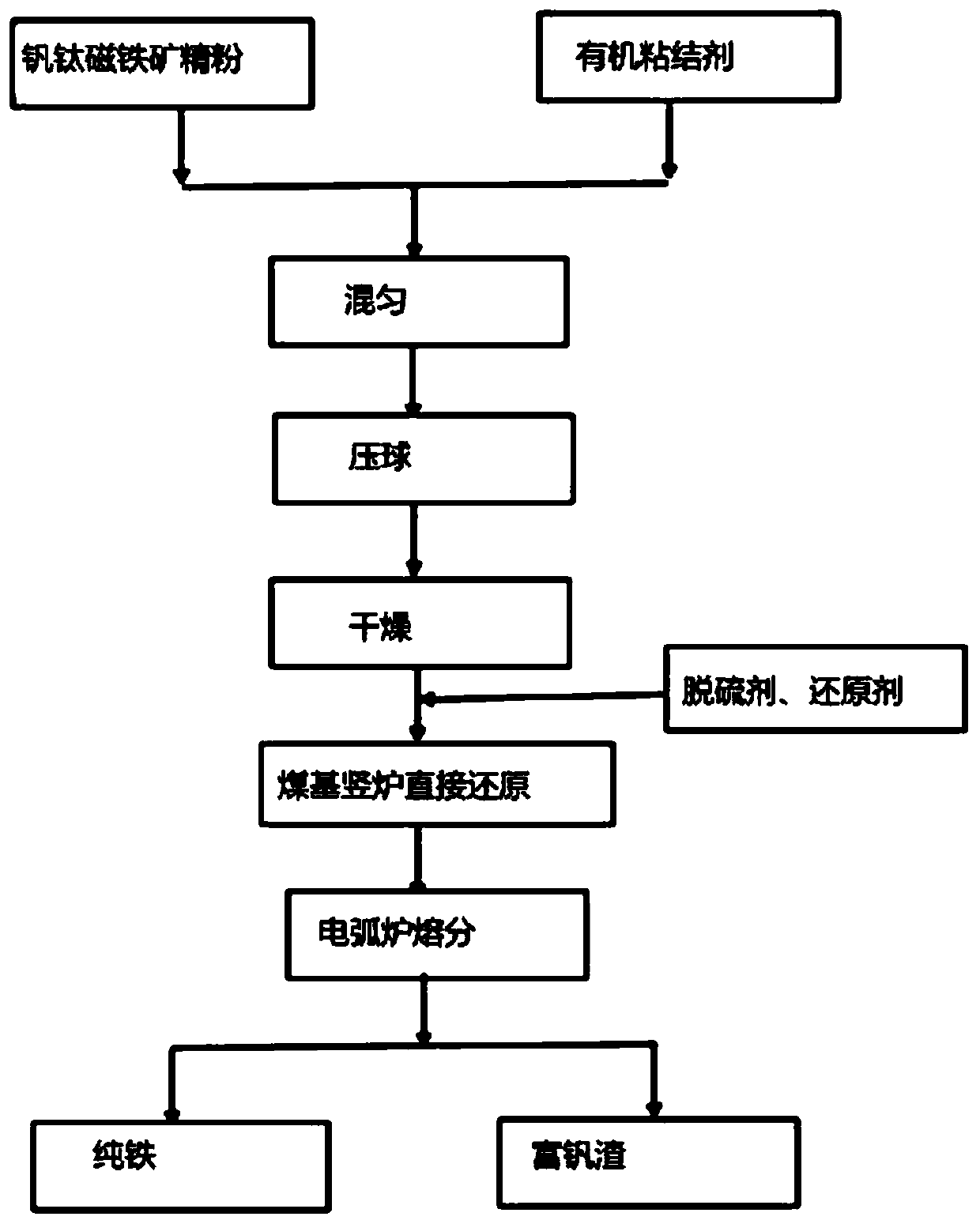

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with embodiment:

[0037] 1. shown in conjunction with process flow chart of the present invention, according to weight percent, vanadium-titanium magnetite concentrate (composition: TFe64.38%FeO29.67%Fe 2 o 3 59.08%TiO 2 2.98%V 2 o 5 0.95%) and binder in a certain ratio (about 1:0.05) for mixing evenly. In the furnace, the reduction temperature is maintained at 1100-1250°C, and the reduction time is controlled to be about 8-9 hours. The average metallization rate of the product is 93.59%. It can be melted directly or melted under a small amount of metallurgical operations to achieve the enrichment of vanadium slag and high recovery of vanadium rate; the recovery rate of vanadium can reach 93.29%, and the grade of vanadium slag is 6.4%. In addition, the composition of the molten steel is 99.75%, the content of silicon is less than 0.001%, the content of manganese is less than 0.001%, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com