Titanium oxide supported cerium zirconium vanadate denitration catalyst, preparation method and application

A denitrification catalyst, cerium vanadate technology, applied in the field of chemical nano-catalysts, to achieve the effect of strong selectivity, good stability, and low vanadium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

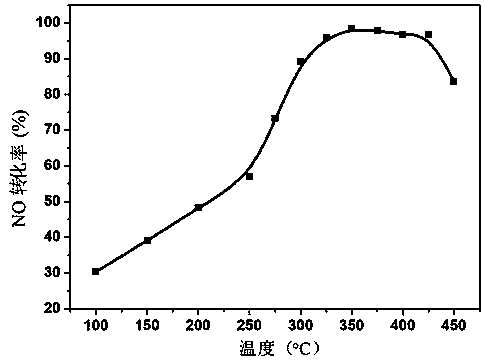

[0034] see figure 1 , the present embodiment provides a preparation method of titania-supported cerium-zirconium vanadate denitration catalyst, which comprises the following steps:

[0035] (1) prepare the solution of zirconium nitrate solution and cerium nitrate, mix after stirring, wherein the mol ratio of the metal zirconium element in the zirconium nitrate solution and the metal cerium element in the cerium nitrate solution is 0.15:0.85;

[0036] (2) Add the HNO that has fully used 16mol / L in the mixed solution that step (1) obtains 3 The ammonium metavanadate dissolved in the solution is uniformly stirred, wherein the molar ratio of metal vanadium in the vanadium salt to metal cerium in the cerium salt is 1:0.85;

[0037] (3) add TiO in the mixed solution that step (2) obtains 2 Carrier, stirring and impregnating;

[0038] (4) drying the mixed solution obtained in step (3) at 80° C. for 16 hours to obtain a precursor of titania-supported cerium-zirconium vanadate denit...

Embodiment 2

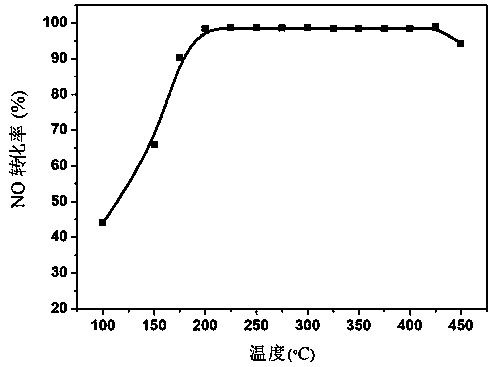

[0045] see figure 2 , the present embodiment provides a preparation method of titania-supported cerium-zirconium vanadate denitration catalyst, which comprises the following steps:

[0046] (1) prepare the solution of zirconium nitrate solution and cerium nitrate, mix after stirring, wherein the mol ratio of the metal zirconium element in the zirconium nitrate solution and the metal cerium element of the cerium nitrate solution is 0.15:0.85;

[0047] (2) Add the HNO that has fully used 16mol / L in the mixed solution that step (1) obtains 3 The ammonium metavanadate dissolved in the solution is uniformly stirred, wherein the molar ratio of metal vanadium in the vanadium salt to metal cerium in the cerium salt is 1:0.85;

[0048] (3) add TiO in the mixed solution that step (2) obtains 2 Carrier, stirring and impregnating;

[0049] (4) drying the mixed solution obtained in step (3) at 100° C. for 12 hours to obtain a precursor of titania-supported cerium-zirconium vanadate den...

Embodiment 3

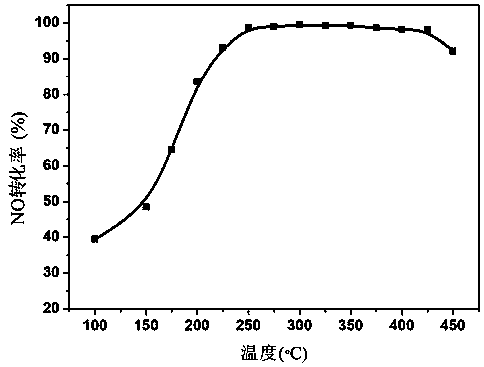

[0056] This embodiment provides a preparation method of the above-mentioned titania-supported cerium-zirconium vanadate denitration catalyst, which includes the following steps:

[0057] (1) prepare the solution of zirconium chloride solution and cerium chloride, mix after stirring, wherein the mol ratio of the metal zirconium element in the zirconium chloride solution and the metal cerium element of the cerium chloride solution is 0.20:0.80;

[0058] (2) in the mixed solution that step (1) obtains, add the sodium metavanadate fully dissolved with the HCl solution of 12mol / L, stir evenly, wherein the mol ratio of metal vanadium in the vanadium salt and metal cerium in the cerium salt is 1 :0.80;

[0059] (3) add TiO in the mixed solution that step (2) obtains 2 Carrier, stirring and impregnating;

[0060] (4) drying the mixed solution obtained in step (3) at 120° C. for 10 h to obtain a precursor of titania-supported cerium-zirconium vanadate denitration catalyst;

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com