Method for preparing lithium battery diaphragm from PE-PP orange flake type composite spun ultrafine fiber

A lithium battery separator, PE-PP technology, applied in the direction of fiber type, fiber treatment, textile and paper making, etc., can solve the problems of unenvironmental protection and pollution, and achieve the effect of large porosity, high safety and stable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

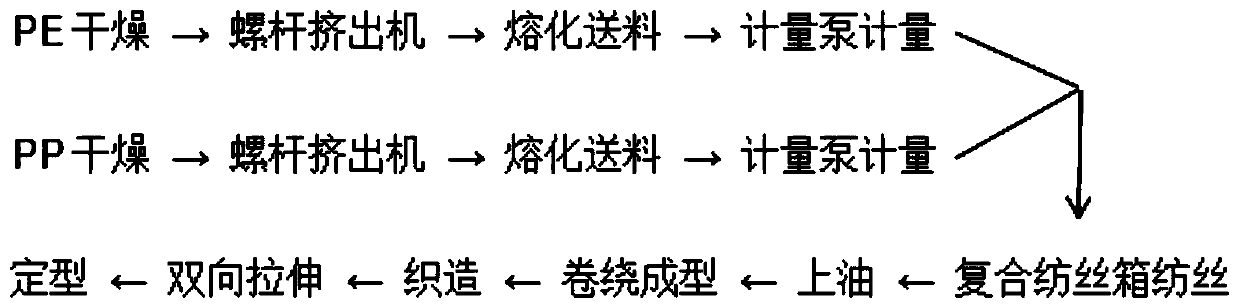

[0025] A method for manufacturing lithium battery diaphragms from PE-PP orange segment composite spinning ultrafine denier fibers

[0026] 1. This embodiment is realized by the requirements of the following equipment

[0027] (1) Two screws: aspect ratio ≥ 32:1, compression ratio ≥ 3.4: 1;

[0028] (2) Two sets of drying systems: drying effect ≤ 100ppm;

[0029] (3) A set of composite spinning box;

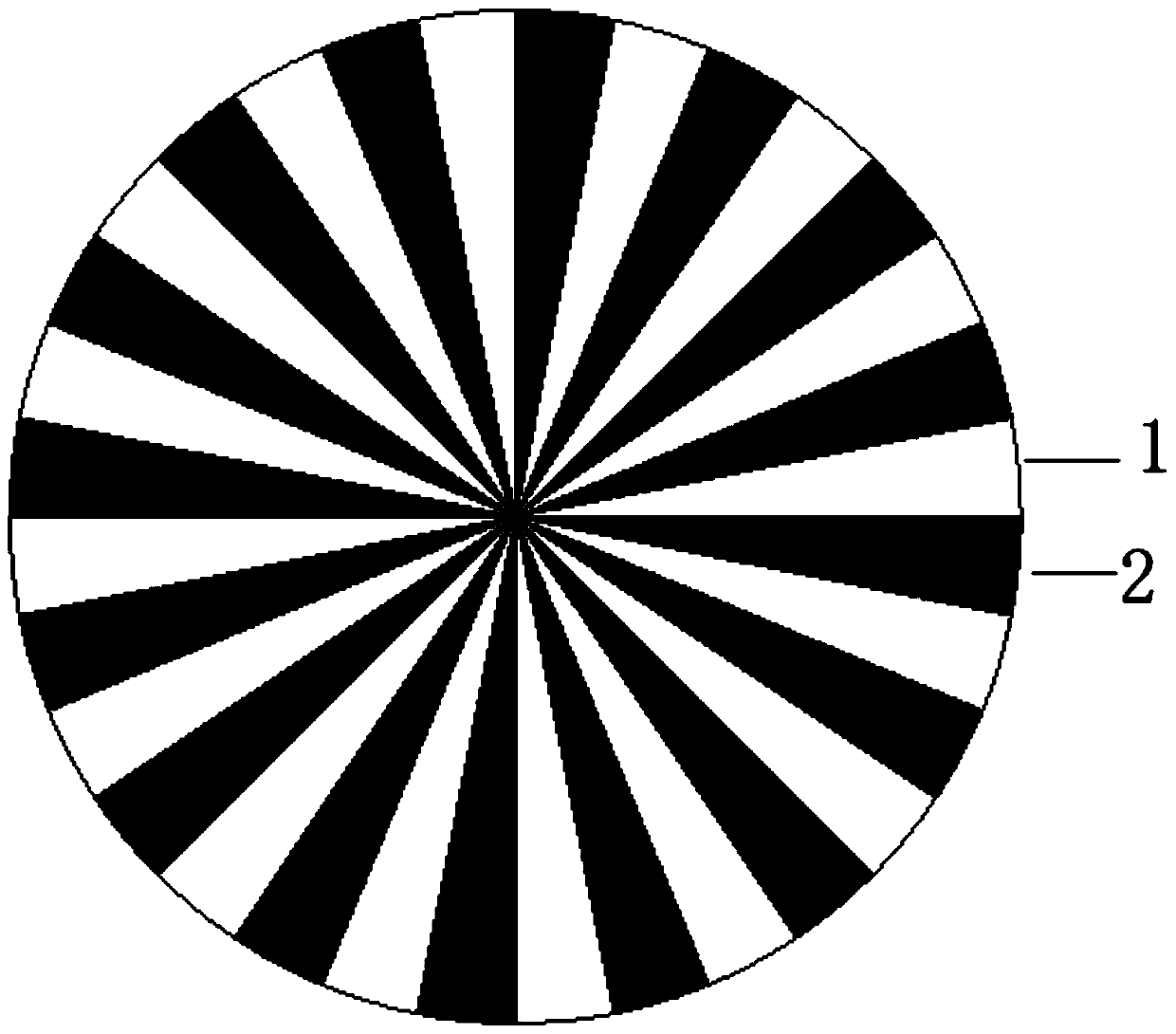

[0030] (4) Orange petal-shaped components: the spinneret has 48 holes and 32 petals;

[0031] (5) Side blowing oiling device and winding forming device;

[0032] (6) Weaving equipment;

[0033] (7) Two-way stretching and heat setting equipment.

[0034] 2. This embodiment requires raw and auxiliary materials

[0035] (1) Fusion refers to PP raw materials with MFR ≥ 30;

[0036] (2) Fusion refers to PE raw materials with MFR ≥ 25;

[0037] (3) Spinning oil containing silicone oil.

[0038] 3. Conditions to be controlled in this embodiment

[0039] (1) The drying temperatu...

Embodiment 2

[0059] Using 80D / 48F 32 petals as the warp and 50D / 48F32 petals as the weft ultra-fine denier to manufacture lithium battery separators

[0060] 1. Preparation of POY superfine denier fiber of 80D / 48F 32 petals

[0061] (1) Production process: PE and PP are dried at a temperature of 65-70°C respectively, and the equipment is dried for 2-3 hours, respectively put into PE and PP screw extruders to melt evenly, and measured by metering pumps (50% each) , sent to the composite assembly in the composite spinning box for composite spinning, cooled by side blowing, oiled, and wound at a spinning speed of 3000m / min to obtain ultra-fine denier segmented fibers, such as figure 2 shown.

[0062] (2) Process control:

[0063] PE screw temperature 260-270°C, screw pressure 8.5MPa;

[0064] PP screw temperature 260-280°C, screw pressure 8.5MPa;

[0065] Spinning box temperature 260-270°C, component pressure 7.5MPa;

[0066] The air temperature of side blowing is 18°C, the wind speed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| impermeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com