Trough-tower combined steam generation system

A generation system and steam technology, applied in the field of solar thermal radiation, can solve the problems of small footprint of solar heat radiation collection devices, affecting the efficiency of steam turbines, affecting the efficiency of photoelectric conversion, etc., to simplify the system complexity, reduce investment costs and plant costs The effect of power consumption rate and improvement of photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

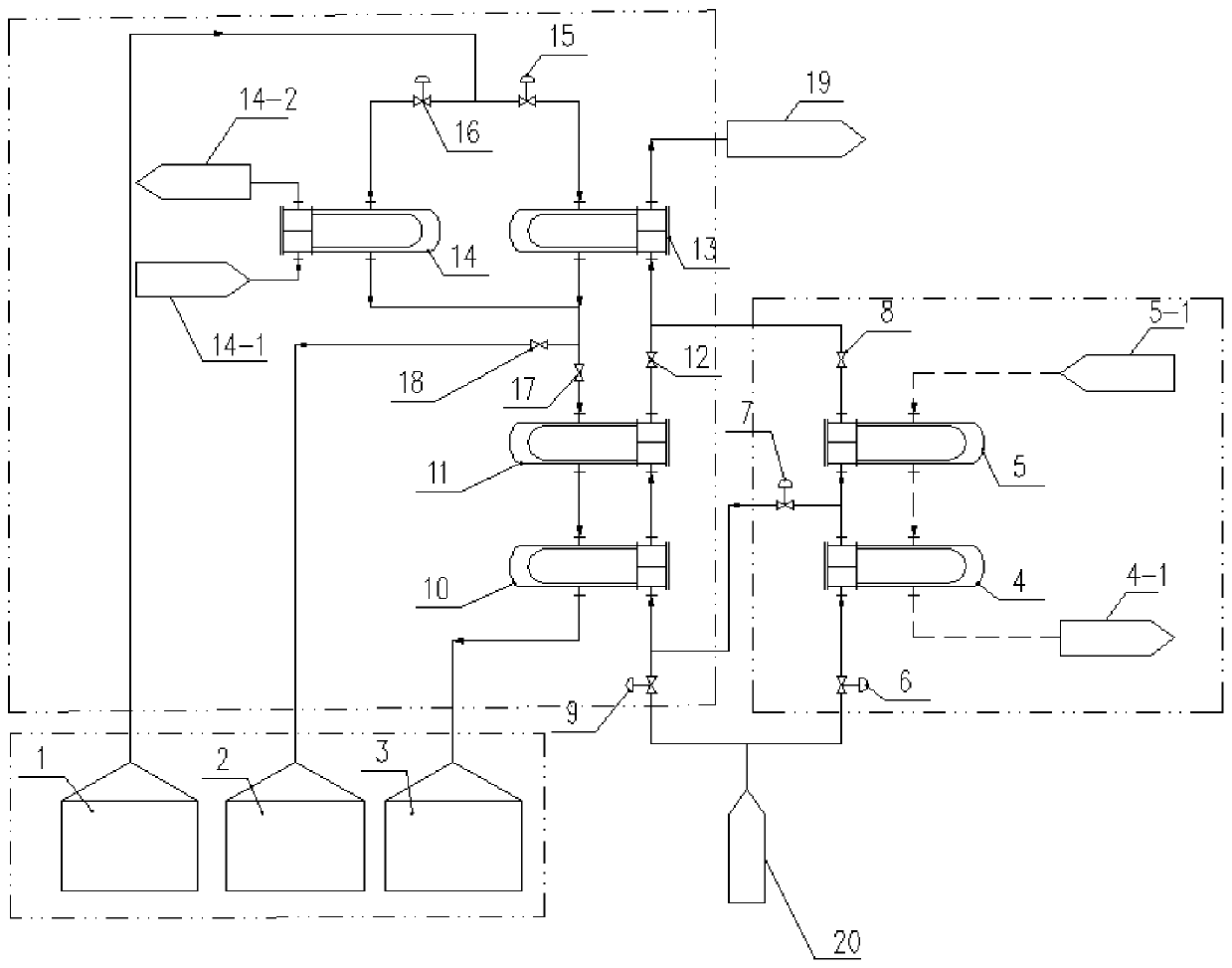

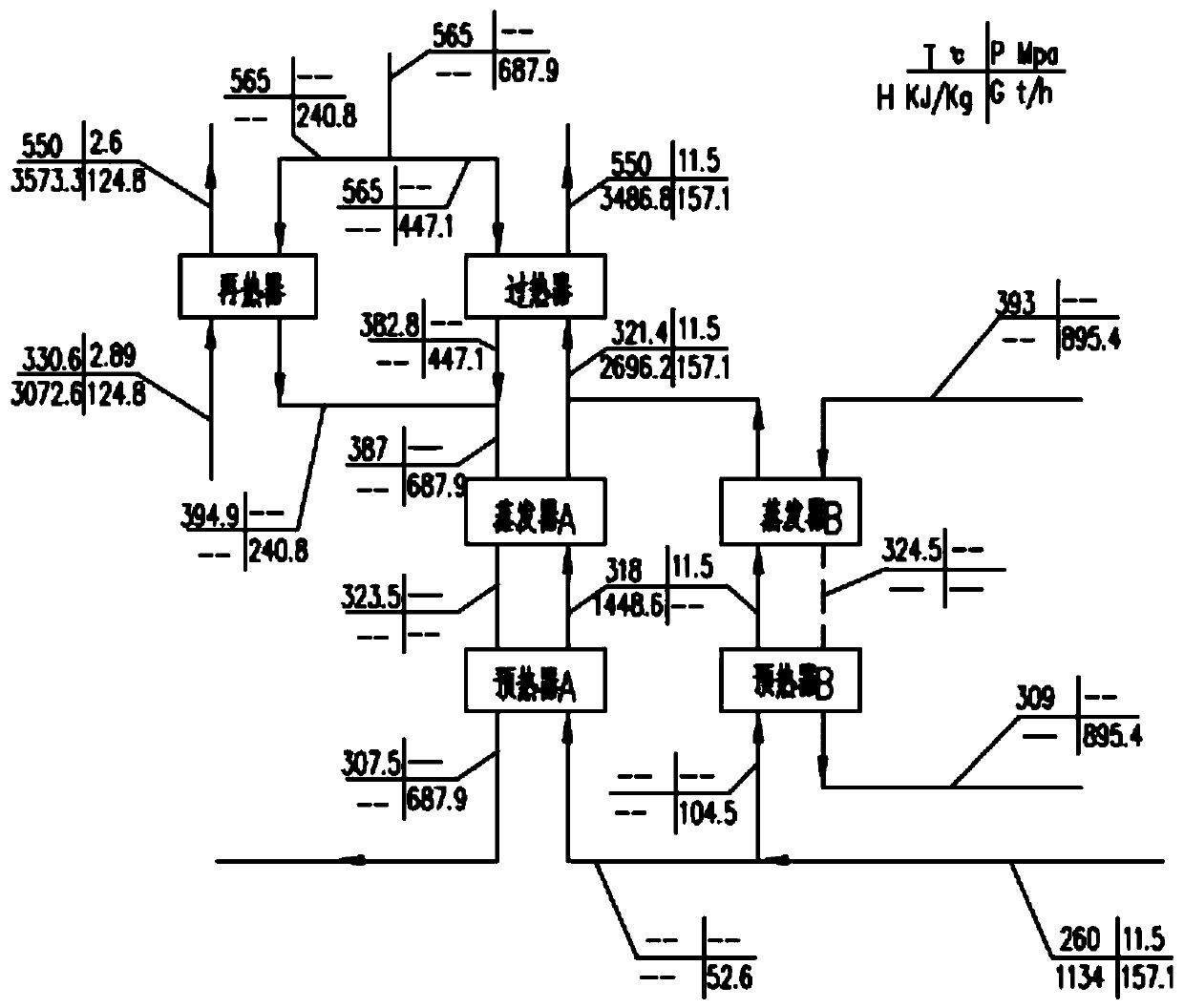

[0021] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, a trough-tower combined steam generation system described in this embodiment includes an energy storage system, a trough-type heat transfer oil steam generation system, a tower-type molten salt steam generation system, and a water supply system 20. The energy storage system and the tower The tower type molten salt steam generation system and the trough type heat transfer oil steam generation system are connected to the water supply system 20, and the tower type molten salt steam generation system is connected to the trough type heat transfer oil steam generation system .

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the tower type molten salt steam generation system described in this embodiment includes a molten salt preheater 10, a molten salt evaporator 11, a molten salt superheater 13 and a molten salt reheater 14,

[0023] The molten salt superheater 13 and the molten salt reheater 14 are all connected to the molten salt evaporator 11, and the molten salt evaporator 11 is connected to the molten salt preheater 10; the molten salt preheater 10, the molten salt evaporator 11, the molten salt Both the superheater 13 and the molten salt reheater 14 are connected to the energy storage system.

[0024] During normal operation, the feed water flow rate is controlled by controlling the valve opening of the feed water regulating valve 9, and the temperature of the water entering the molten salt preheater 10 is controlled by controlling the opening of the regulating valve 7, and enters th...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the energy storage system described in this embodiment includes a high-temperature salt tank 1, a medium-temperature salt tank 2 and a low-temperature salt tank 3,

[0028] The high-temperature salt tank 1 is connected to the molten salt reheater 14 and the molten salt superheater 13 respectively, the medium-temperature salt tank 2 is connected to the molten salt superheater 13 , and the low-temperature salt tank 3 is connected to the molten salt preheater 10 .

[0029] Among them, the high temperature salt tank 1 is used to store the energy storage of the tower type molten salt heat collection system, and the medium temperature salt tank 2 is used for the energy storage of the trough heat transfer oil heat collection system and after heat exchange with the molten salt superheater and molten salt reheater molten salt, and the low-temperature salt tank 3 is used to store the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com