SERS substrate and preparation method thereof

A substrate and substrate technology, applied in the field of analytical chemistry, can solve the problems of high repeatability and good reliability, and achieve the effect of simple operation, high repeatability and delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

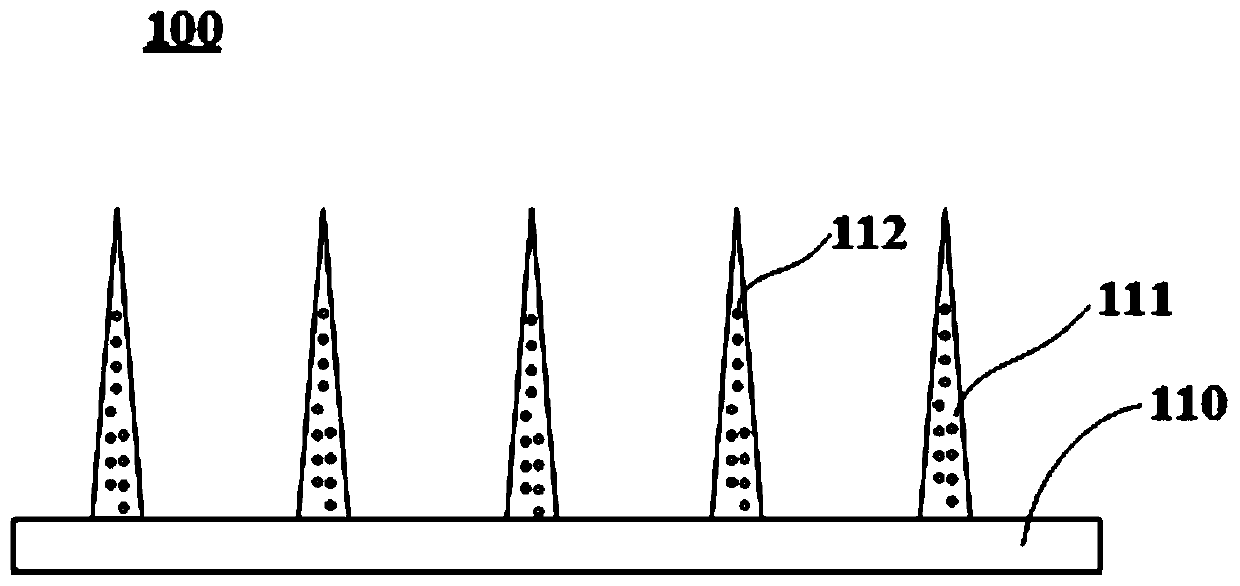

[0043] In this embodiment, a SERS substrate 100 is provided, the SERS substrate has figure 1 structure shown. Wherein, the substrate 110 is made of silicon, the tip diameter of the microneedles 111 is set to 5 nanometers, the height of the microneedles 111 is set to 100 microns, and the distance between the central axes of adjacent microneedles 111 is set to 300 microns. And, the microneedles 111 are evenly distributed in 9 rows×9 columns.

[0044] The specific preparation steps of the SERS substrate are as follows.

[0045] (1) Preparation of gold nanoparticles

[0046] Heat 50mL of 1mmol / L chloroauric acid solution in a 250mL flask to boiling state, then add 1.85mL of 38.8mmol / L trisodium citrate dropwise, keep boiling and reflux for 15min, put into brown reagent bottle after cooling Save it for later use.

[0047] (2) Concentrated nanoparticles

[0048] Take 5 mL of the nano-gold sol obtained in step (1) and put it into a centrifuge, centrifuge at 5000 rpm for 5 minutes,...

Embodiment 2

[0054] In this embodiment, a SERS substrate 100 is provided, the SERS substrate has figure 1 structure shown. Wherein, the substrate 110 is made of silicon, the tip diameter of the microneedles 111 is set to 5 nanometers, the height of the microneedles 111 is set to 100 microns, and the distance between the central axes of adjacent microneedles 111 is set to 300 microns. And, the microneedles 111 are evenly distributed in 9 rows×9 columns.

[0055] The specific preparation steps of the SERS substrate are as follows.

[0056] (1) Preparation of silver nanoparticles.

[0057] Weigh 36 mg of silver nitrate and dissolve it in 200 mL of deionized water, heat the solution to boiling, slowly add 6 mL of 1% (mass fraction) trisodium citrate solution dropwise under stirring, continue stirring after the addition is complete, and keep the solution boiling for 15 min , and finally cool the prepared silver colloid to room temperature.

[0058] (2) Concentrated nanoparticles

[0059] C...

Embodiment 3

[0065] In this embodiment, a SERS substrate 100 is provided, the SERS substrate has figure 1 structure shown. Wherein, the substrate 110 is made of silicon, the tip diameter of the microneedles 111 is set to 200 nanometers, the height of the microneedles 111 is set to 200 microns, and the distance between the central axes of adjacent microneedles 111 is set to 500 microns. Moreover, the microneedles 111 are evenly distributed in 9 rows×9 columns.

[0066] The preparation method is as described in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com