AgNR/O-g-C3N4 substrate, preparation method and application thereof in recyclable SERS sensitive detection

An o-g-c3n4, m-o-g-c3n4 technology, applied in the application of cyclable SERS sensitive detection, AgNR/O-g-C3N4 substrate field, can solve the problems of weak reusability, oxidation, SERS activity reduction, etc., to achieve high reproducibility properties and stability, improved stability, and the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

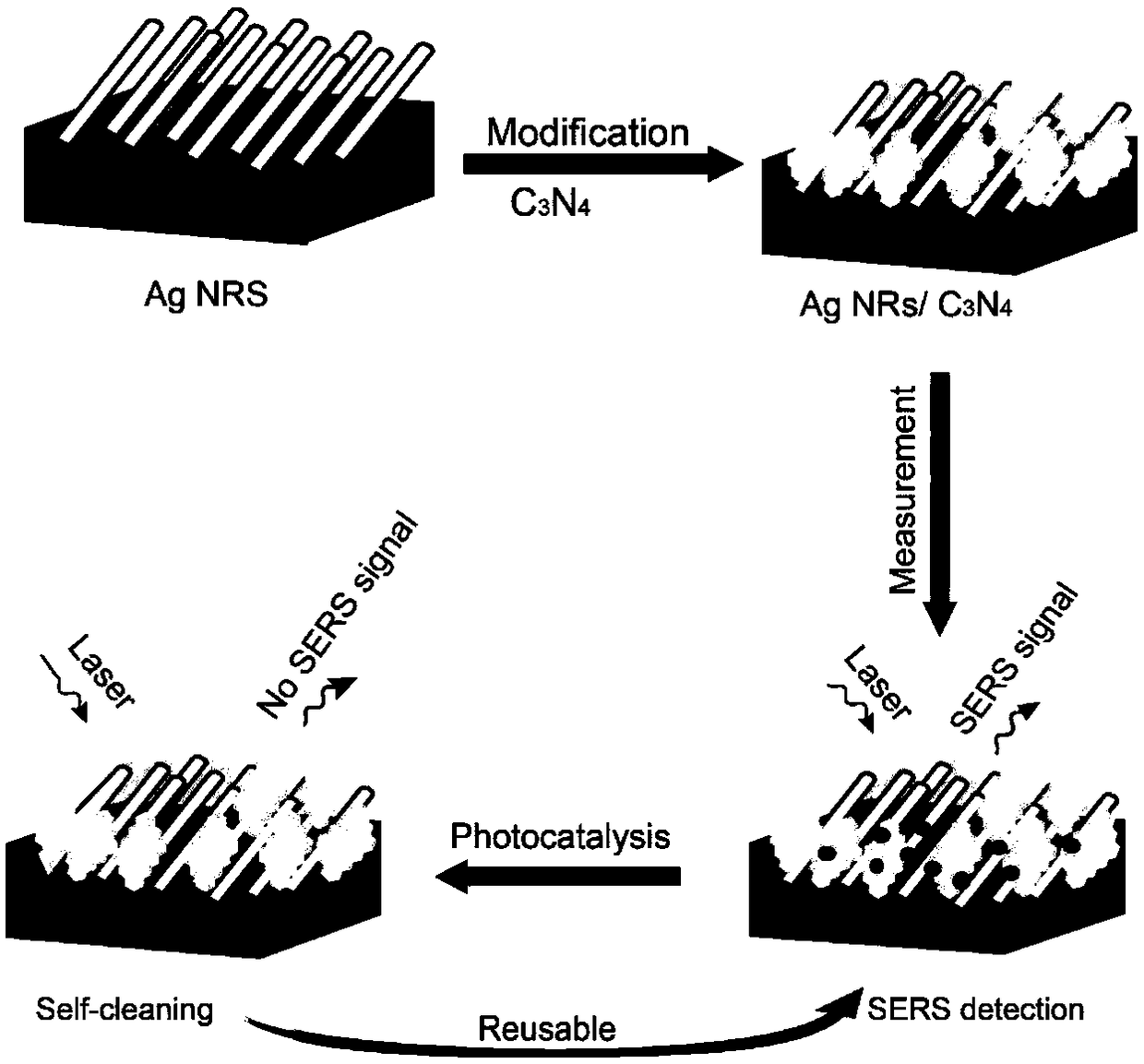

[0027] Example 1 AgNR / O-g-C 3 N 4 Preparation of substrate

[0028] 1. Preparation of AgNR Arrays

[0029] Glass slides were cleaned in piranha solution (80% sulfuric acid, 20% hydrogen peroxide), rinsed with deionized water, and dried under a nitrogen atmosphere. Then, place the cleaned slide on the deposition platform. In an electron beam evaporator (DE500 electron beam evaporation deposition method), at 1×10 -6 Under the pressure of Torr, a 20nm titanium film and a 500nm silver film system were deposited at a rate of 0.2nm / s and 0.3nm / s, respectively. Then the deposition table was rotated at a deposition angle of 86°, and a 2000 nm silver film was deposited at a rate of 0.3 nm / s to obtain an AgNR array.

[0030] 2. Preparation of Monolayer O-g-C 3 N 4

[0031] First, melamine (2 g) was placed in a muffle furnace, and the temperature was raised to 550° C. at a rate of 2° C. / min, and calcined for 4 hours. Then, the melamine was naturally cooled to room temperature to...

Embodiment 2

[0034] Example 2 AgNR / O-g-C 3 N 4 Determination of properties of the substrate

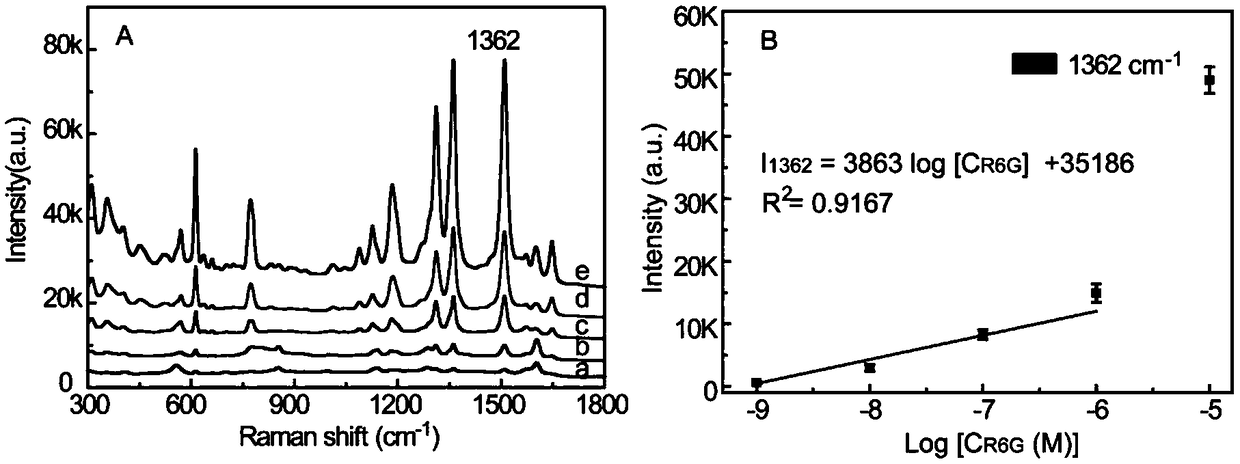

[0035] 1. AgNR / O-g-C 3 N 4 SERS Sensitivity Determination of Substrates

[0036] To prepare standard solutions of various concentrations, 10 -3 The R6G solution of M was diluted to a concentration of 1.0×10 -5 M to 1.0×10 -9 M's solution. For each sample, three SERS spectra were acquired from different positions of the substrate. The laser power is 10mW, the integration time is 5s, the result is as follows image 3 shown. from image 3 It can be seen that the detection limit of R6G is as low as 8.2×10 -10 M, indicating AgNR / O-g-C 3 N 4 The substrate has high detection sensitivity.

[0037] 2. AgNR / O-g-C 3 N 4 Stability determination of the substrate

[0038] Place the same substrate in the air and detect 5×10 R6G every 7 days -5 The signal of M, the detection result is as follows Figure 4 shown, from Figure 4 It can be seen that the SERS signal of R6G hardly changed after 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com