Method for determining the content of acetonitrile in a sample

A sample and acetonitrile technology, applied in the field of determining the content of acetonitrile in the sample, can solve the problems of inability to measure the purity of acetonitrile, the inability to accurately measure the purity of acetonitrile, low acetonitrile, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

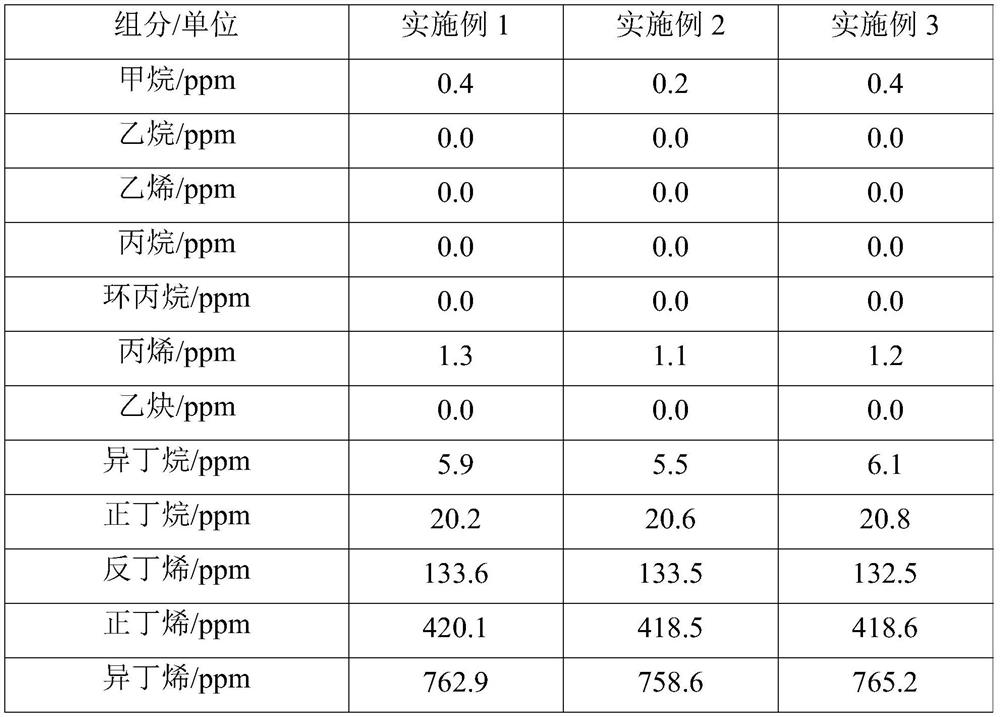

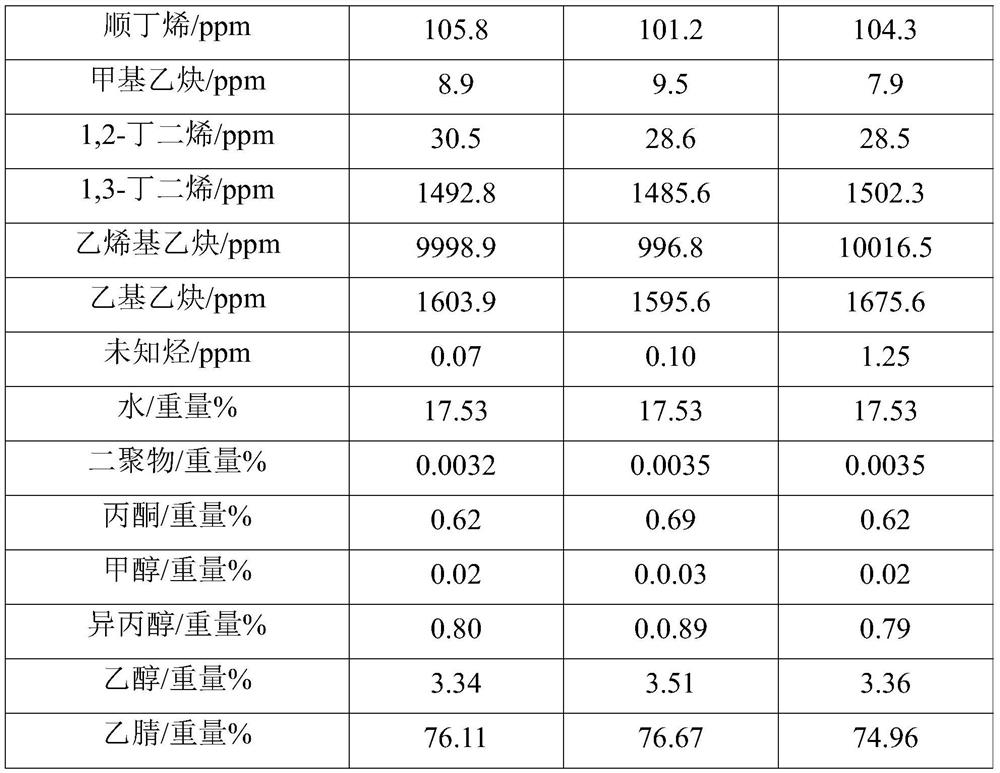

Embodiment 1

[0029] Add 0.5 μL of sample 1 to be tested into column 1 for measurement, and control the carrier gas N 2 The flow rate is 3mL / min, the split ratio is 60:1, and the column temperature is controlled at 50°C for 10 minutes, then raised to 230°C at 20°C / min for 5 minutes; then 1 μL of sample 1 to be tested is added to column 2 for determination , control carrier gas N 2 The flow rate is 5mL / min, the split ratio is 5:1, and the column temperature is controlled at 40°C for 5 minutes, then raised to 60°C at 2°C / min, then raised to 100°C at 3°C / min, and then at 10°C ℃ / min rises to 180 ℃ for 7 minutes, and the valve cut time is 4 minutes.

[0030] Then, according to the external standard method, methanol, ethanol, isopropanol, acetone and dimers of known content were added to the column 1 respectively, and measured with the same chromatographic conditions as described above, and then the C1- C4 hydrocarbons were added to column 2 respectively, and measured under the same chromatogra...

Embodiment 2

[0032] Add 0.5 μL of sample 1 to be tested into column 1 for measurement, and control the carrier gas N 2 The flow rate is 2.5mL / min, the split ratio is 60:1, and the column temperature is controlled at 45°C for 11 minutes, and then raised to 225°C at 18°C / min for 4 minutes; then 1 μL of sample 1 to be tested is added to column 2 for Determination, control carrier gas N 2 The flow rate is 4.5mL / min, the split ratio is 5:1, and the column temperature is controlled at 35°C for 6 minutes, then raised to 65°C at 2°C / min, then raised to 105°C at 3°C / min, and then 11 ℃ / min rise to 185 ℃ constant temperature 8 minutes, the valve cut time is 3.8 minutes.

[0033] Then according to the external standard method, add methanol, ethanol, isopropanol, acetone and dimers of known content into column 1 respectively, and measure with the same chromatographic conditions as above, and then add the C1-C4 The hydrocarbons were added to the column 2 respectively, and measured under the same chr...

Embodiment 3

[0035] Add 0.5 μL of sample 1 to be tested into column 1 for measurement, and control the carrier gas N 2 The flow rate is 3.5mL / min, the split ratio is 60:1, and the column temperature is controlled at 55°C for 9 minutes, and then raised to 235°C at 22°C / min for 6 minutes; then 1 μL of sample 1 to be tested is added to column 2 for Determination, control carrier gas N 2 The flow rate is 5.5mL / min, the split ratio is 5:1, and the column temperature is controlled at 45°C for 4 minutes, then raised to 55°C at 1.5°C / min, then raised to 95°C at 2°C / min, and then 9°C / min rises to 175°C for 6 minutes, and the valve cut-off time is 4.2 minutes.

[0036] Then, according to the external standard method, methanol, ethanol, isopropanol, acetone and dimers of known content were added to the column 1 respectively, and measured with the same chromatographic conditions as described above, and then the C1- C4 hydrocarbons are respectively added in the column 2, and are measured with the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com