Iron-based spheroidized micro-nano magnetic powder core and preparation method thereof

A magnetic powder core, micro-nano technology, applied in the direction of magnetic core manufacturing, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of difficult to increase effective density, low tonnage of magnetic powder core, poor insulation, etc., to achieve effective density increase, Improve the pressing tonnage and reduce the effect of secondary embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

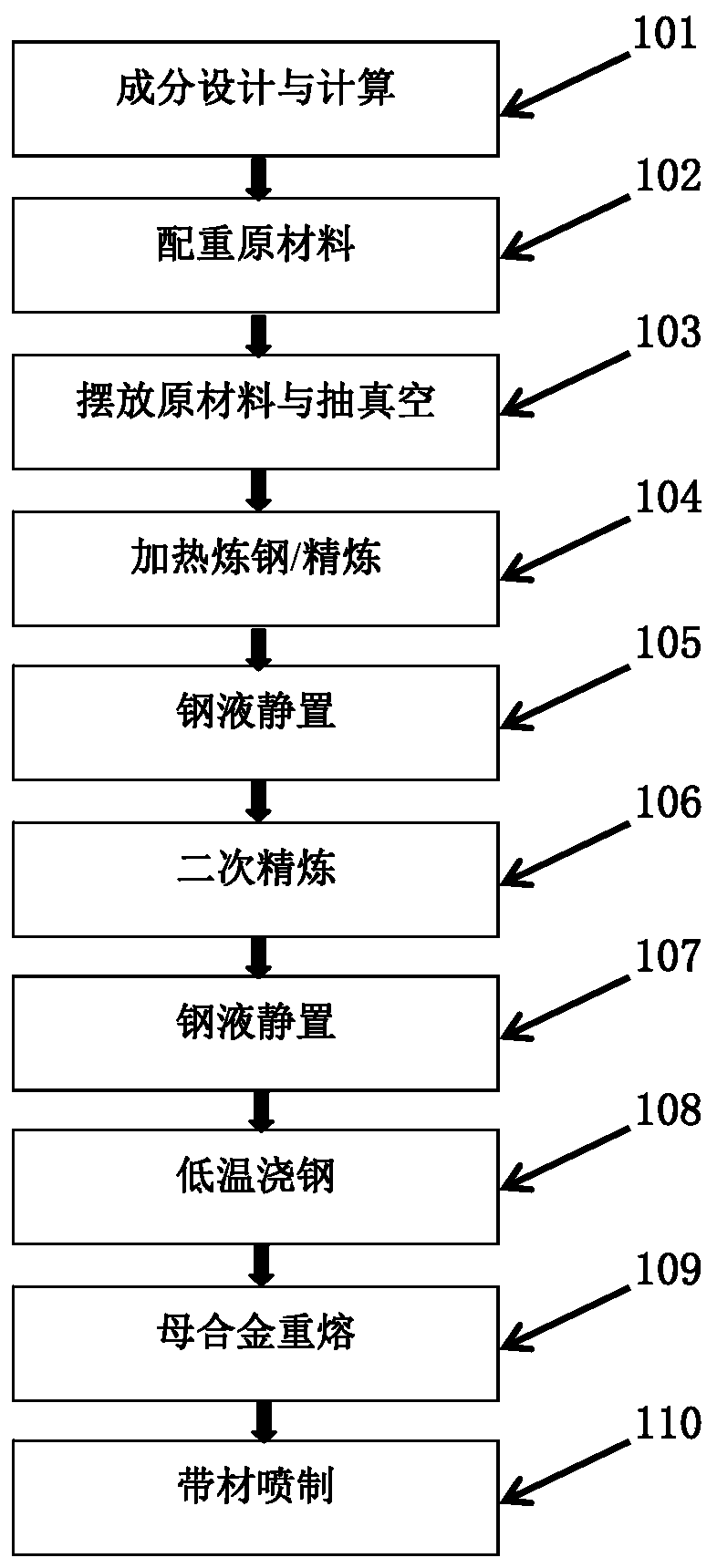

[0030] Such as figure 1 As shown, the preparation process of the quenched strip is as follows:

[0031] 101: Alloy composition design, based on the atomic size difference of iron-based amorphous components, mixing enthalpy, component diversification and addition, fine-tuning the influence of elements on the microstructure and macroscopic magnetic properties as design criteria, but determined that Fe is 83.5wt% , Si is 8.6wt%, B is 1.75wt%, Nb is 4.0wt%, Mo is 1.0wt%, Cu is 1.0wt%, Ni is 0.15wt%;

[0032] 102: According to the designed alloy composition, the selected raw materials are electrical pure titanium, industrial silicon, ferro-niobium, ferro-molybdenum, ferro-boron, electrolytic copper and electrolytic nickel, and the weight master alloy material is 200kg;

[0033]103: Place the raw materials, put electrical pure titanium, industrial silicon, ferro-niobium, ferro-molybdenum, ferro-boron, electrolytic copper and electrolytic nickel, and counterweight master alloy mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com