Silicon-based negative electrode material for lithium ion batteries, and preparation method and application thereof

A technology for silicon-based negative electrode materials and lithium-ion batteries, which can be used in electrode manufacturing, battery electrodes, and secondary batteries. Excellent, prolonging the service life and enhancing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The embodiment of the present invention also provides a method for preparing a silicon-based negative electrode slurry for a lithium ion battery, comprising the following steps:

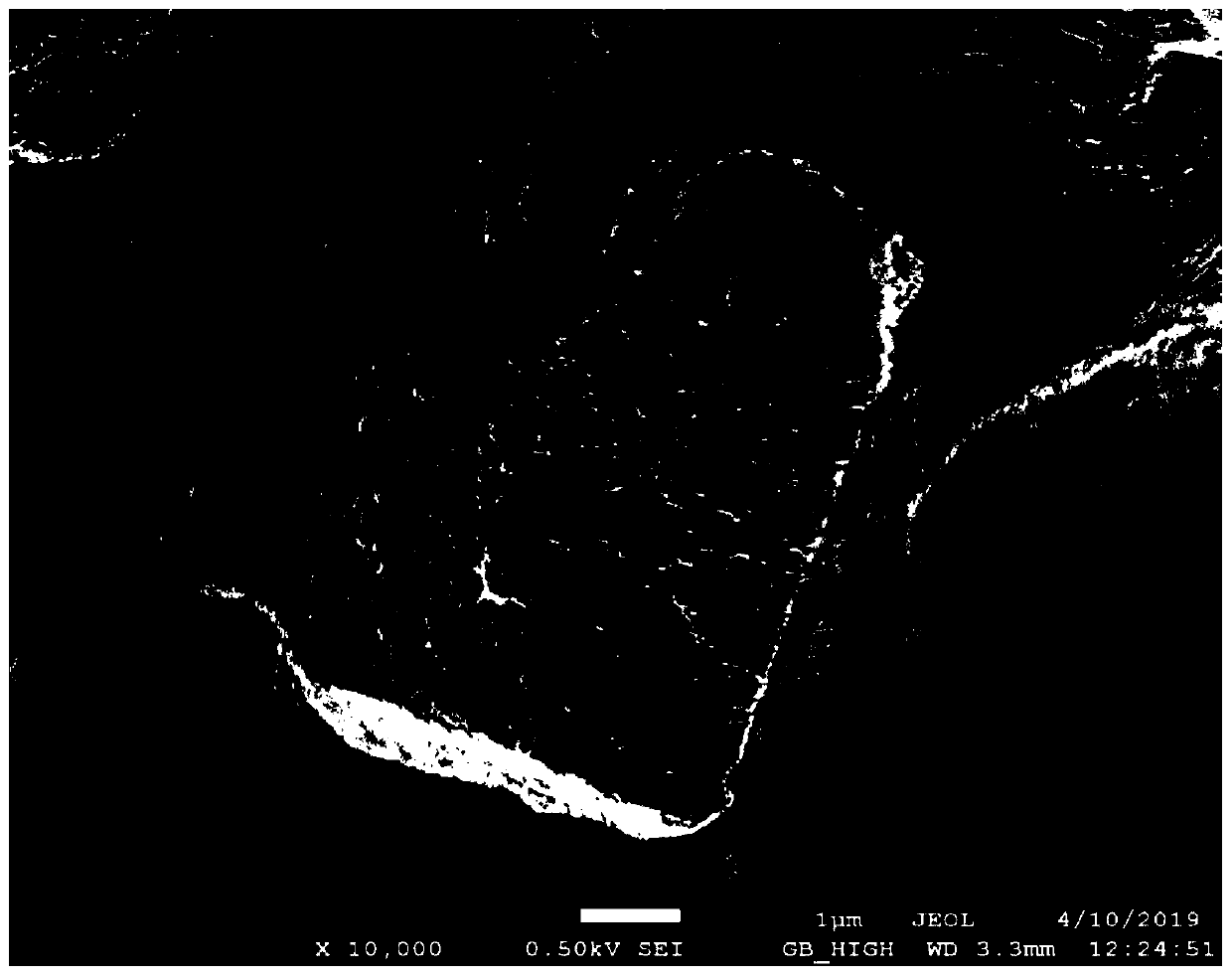

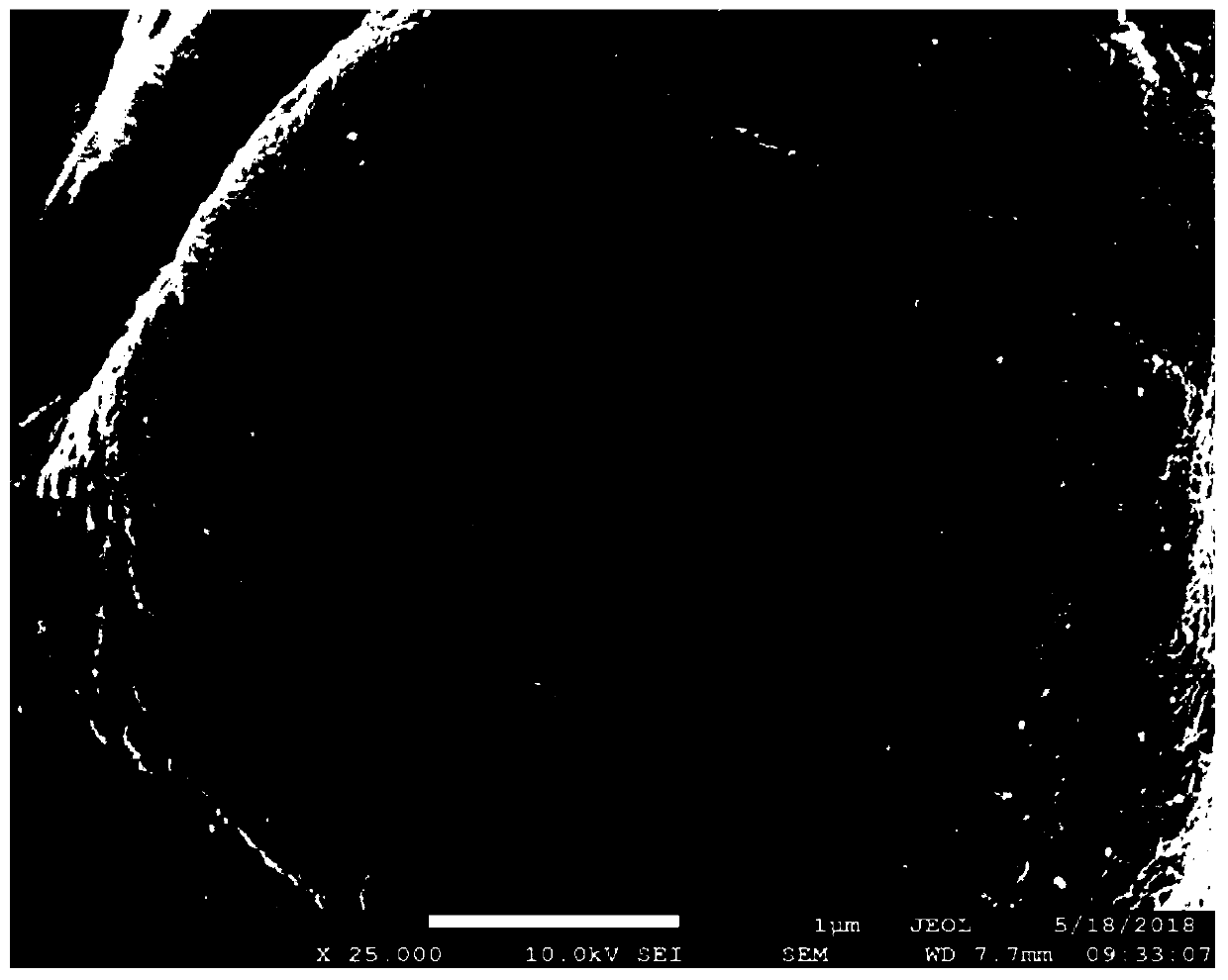

[0074] S10. Obtain a silicon-based functional material and a carbon nanotube conductive agent, and pre-mix the silicon-based functional material and the carbon nanotube conductive agent to obtain a silicon-based functional material coated with carbon nanotubes;

[0075] S20. Obtain a carbon black conductive agent and a thickener. After mixing the carbon black conductive agent and the thickener for the first time, add water to adjust the solid content to 60% to 75%, and perform the second mixing process. Mixing treatment to obtain the second mixed product;

[0076] S30. adding the silicon-based functional material whose surface is coated with carbon nanotubes to the second mixed product, and performing a third mixed treatment to obtain a third mixed product;

[0077] S40. Adding water to adjus...

Embodiment 1

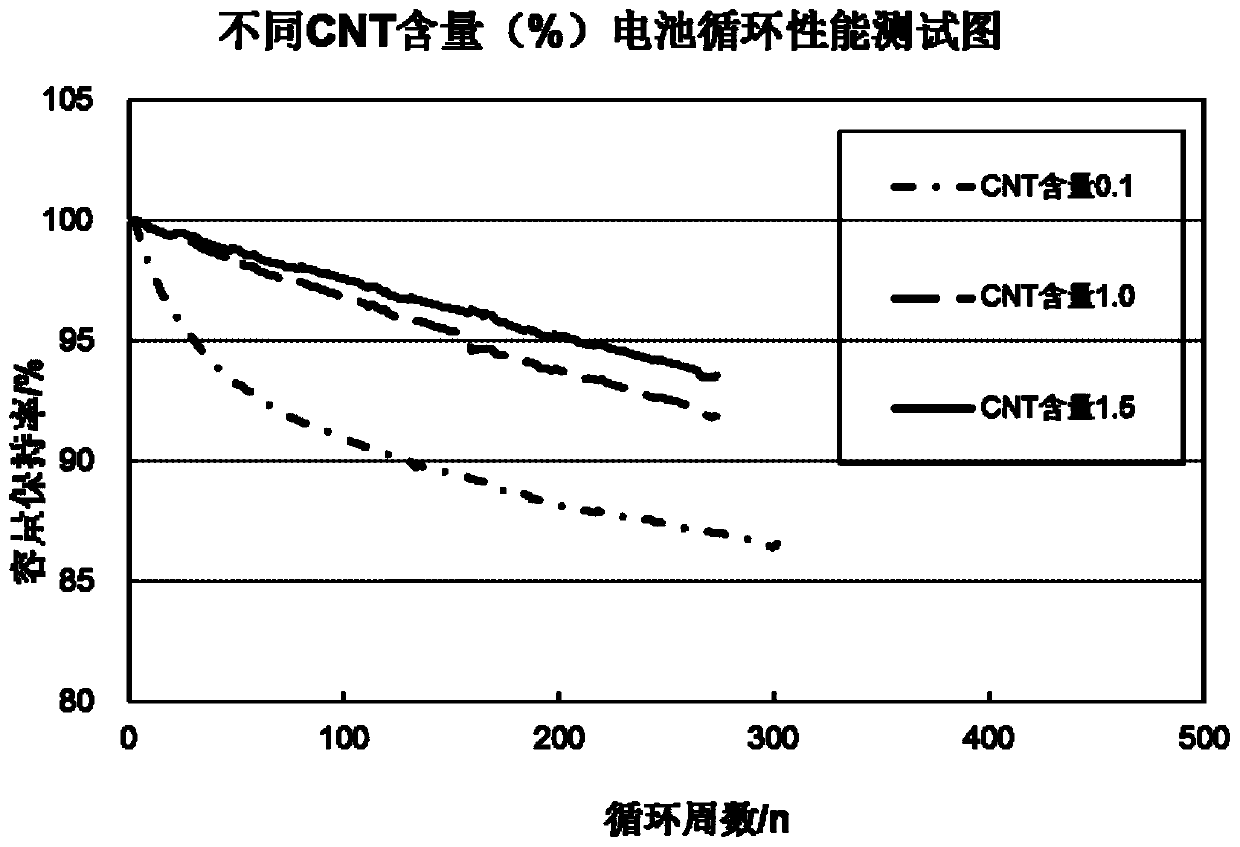

[0099] A silicon-based negative electrode slurry with a carbon nanotube content of 0.1%, the preparation method of which comprises the steps of:

[0100] ① Obtain 302.86g of silicon anode material and 5.51g of carbon nanotube conductive agent, and pre-mix the silicon anode material and carbon nanotube conductive agent at a revolution speed of 15rpm and a rotation speed of 100rpm for 10 minutes to obtain a surface coating Silicon anode materials with carbon nanotubes;

[0101] ② Obtain 5000g of graphene negative electrode material, 27.53g of carbon black conductive agent and 71.59g of thickener, and mix graphene negative electrode material, carbon black conductive agent and thickener at a revolution speed of 15rpm and a rotation speed of 100rpm. After 10 minutes of treatment, add water to adjust the solid content to 60% to 75%, and then mix for 15 minutes at a revolution speed of 15 rpm and a rotation speed of 5 rpm to obtain a second mixed product;

[0102] ③ Add the silicon ...

Embodiment 2

[0106] A silicon-based negative electrode slurry with a carbon nanotube content of 1%, the preparation method of which comprises the steps of:

[0107] ① Obtain 303.20g of silicon anode material and 55.13g of carbon nanotube conductive agent, and pre-mix the silicon anode material and carbon nanotube conductive agent at a revolution speed of 15rpm and a rotation speed of 100rpm for 10 minutes to obtain a surface coating Silicon anode materials with carbon nanotubes;

[0108] ② Obtain 5000g of graphene negative electrode material, 27.56g of carbon black conductive agent and 60.64g of thickener, and mix graphene negative electrode material, carbon black conductive agent and thickener at a revolution speed of 15rpm and a rotation speed of 100rpm. After 10 minutes of treatment, add water to adjust the solid content to 60% to 75%, and then mix for 15 minutes at a revolution speed of 15 rpm and a rotation speed of 5 rpm to obtain a second mixed product;

[0109] ③ Add the silicon a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com