Liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element

A technology of liquid crystal alignment agent and structural unit, which is applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of reduced brightness, increased ion density, interference with grayscale display, etc., and achieves the effect of promoting movement and relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

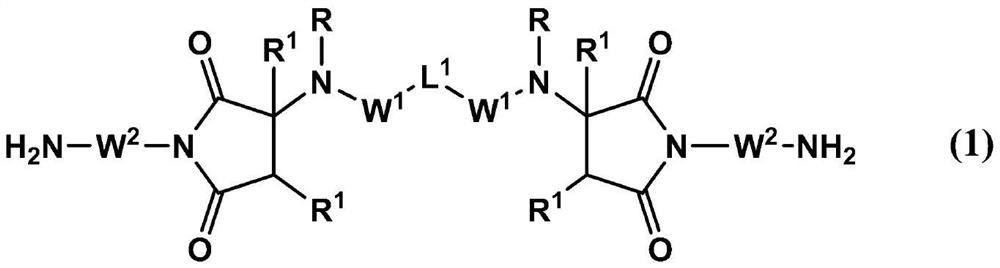

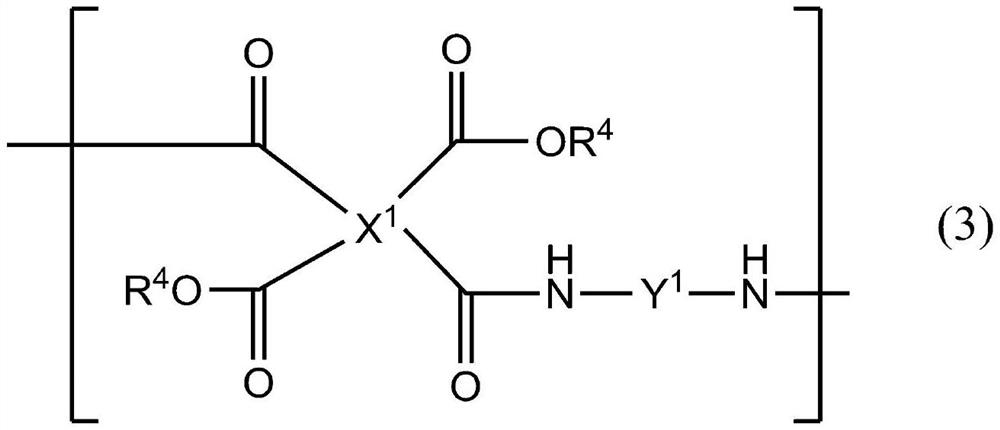

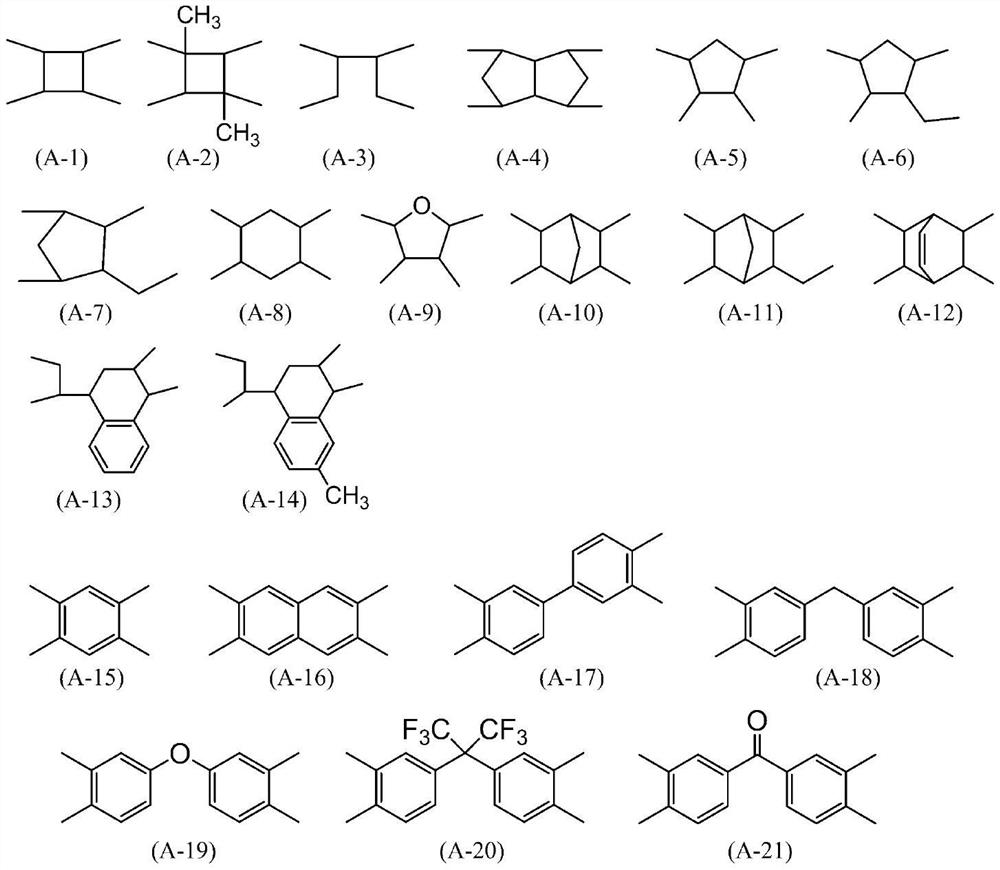

Method used

Image

Examples

Embodiment 1A

[0213] Synthesis of (DA-1-1)

[0214]

[0215] After adding 15.00 g (68.8 mmol) of N-(4-nitrophenyl)maleimide and 300 g of tetrahydrofuran (hereinafter referred to as THF) into the flask, it was ice-cooled. To this mixture was added 3.37 g (33.0 mmol) of N,N'-dimethyl-1,3-propanediamine. Then, after slowly returning to room temperature, the mixture was stirred at room temperature for 1 day. After confirming that the reaction was complete, 200 g of ethyl acetate was added to the reaction mixture and stirred. The resulting crystals were filtered and then dried at 50°C to obtain 11.1 g (yield 62%) of the target nitro compound intermediate (DA-1-1-1).

[0216] 1 H-NMR (D6-DMSO, δppm): 8.37 (d, 4H), 7.62 (d, 4H), 4.15-4.21 (m, 1H), 2.93-3.03 (m, 2H), 2.80-2.89 (m, 2H) ),2.53-2.70(m,4H),2.32(s,6H),1.57-1.67(m,2H)

[0217] DA-1-1-1 11.1 g (20.6 mmol), 5% Pd-C 1 g (STD type, wet product, manufactured by N.E. CHEMCAT Corporation) and N,N-dimethylformamide were charged into a ni...

Embodiment 2A

[0220] Synthesis of (DA-1-2)

[0221]

[0222] After adding 0.1246 g (0.662 mmol) of N-(4-aminophenyl)maleimide and 3 g of THF into the flask, it ice-cooled. To this mixture was added piperazine 0.0285 g (0.331 mmol). Then, after slowly returning to room temperature, the mixture was stirred at room temperature for 3 days. After confirming the completion of the reaction, the precipitated crystals were filtered and washed with diisopropyl ether (hereinafter referred to as IPA). The resulting crystals were dried at 50°C to obtain 0.067 g of the target DA-1-2 (yield 47%).

[0223] 1H-NMR (D6-DMSO, δppm): 6.82 (d, 4H), 6.59 (d, 4H), 5.30 (brs, 4H), 3.92-3.98 (m, 2H), 2.70-2.95 (m, 8H), 2.40-55(m,2H)

Embodiment 3A

[0225] Synthesis of (DA-1-3)

[0226]

[0227] After adding 2.90 g (15.4 mmol) of N-(4-aminophenyl)maleimide and 30 g of tetrahydrofuran (hereinafter referred to as THF) into the flask, it was ice-cooled. To this mixture was added 1.00 g (7.34 mmol) of 4-(aminomethyl)benzylamine. Then, after slowly returning to room temperature, the mixture was stirred at room temperature for 3 hours. After confirming the completion of the reaction, the reaction mixture was cooled again, and the precipitated crystals were filtered. The obtained crystals were dried at 45° C. under reduced pressure to obtain 1.59 g (yield 42%) of the target compound (DA-1-3) as yellow crystals.

[0228] 1H-NMR (D6-DMSO, δppm): 7.32 (s, 4H), 6.84 (d, 4H), 6.59 (d, 4H), 5.31 (brs, 4H), 3.82-3.95 (m, 4H), 3.74- 3.82(m,2H),2.91-3.01(m,2H),2.94(brs,2H),2.53-2.56(m,1H),2.48-2.51(m,1H)

[0229] [Viscosity determination]

[0230] The viscosity of the polyamic acid solution was measured using an E-type viscometer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com