Liquid crystal aligning agent, liquid crystal alignment film and liquid crystal display element

A liquid crystal alignment agent, liquid crystal technology, applied in the direction of instruments, optics, nonlinear optics, etc., to achieve the effect of excellent display characteristics, not easy to flicker, and promote movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0163] Hereinafter, examples and the like are given and the present invention will be specifically described, but the present invention is not limited to these examples. In addition, the abbreviation of a compound and a solvent is as follows.

[0164] NMP: N-methyl-2-pyrrolidone GBL: γ-butyrolactone

[0165] BCS: Butyl Cellosolve

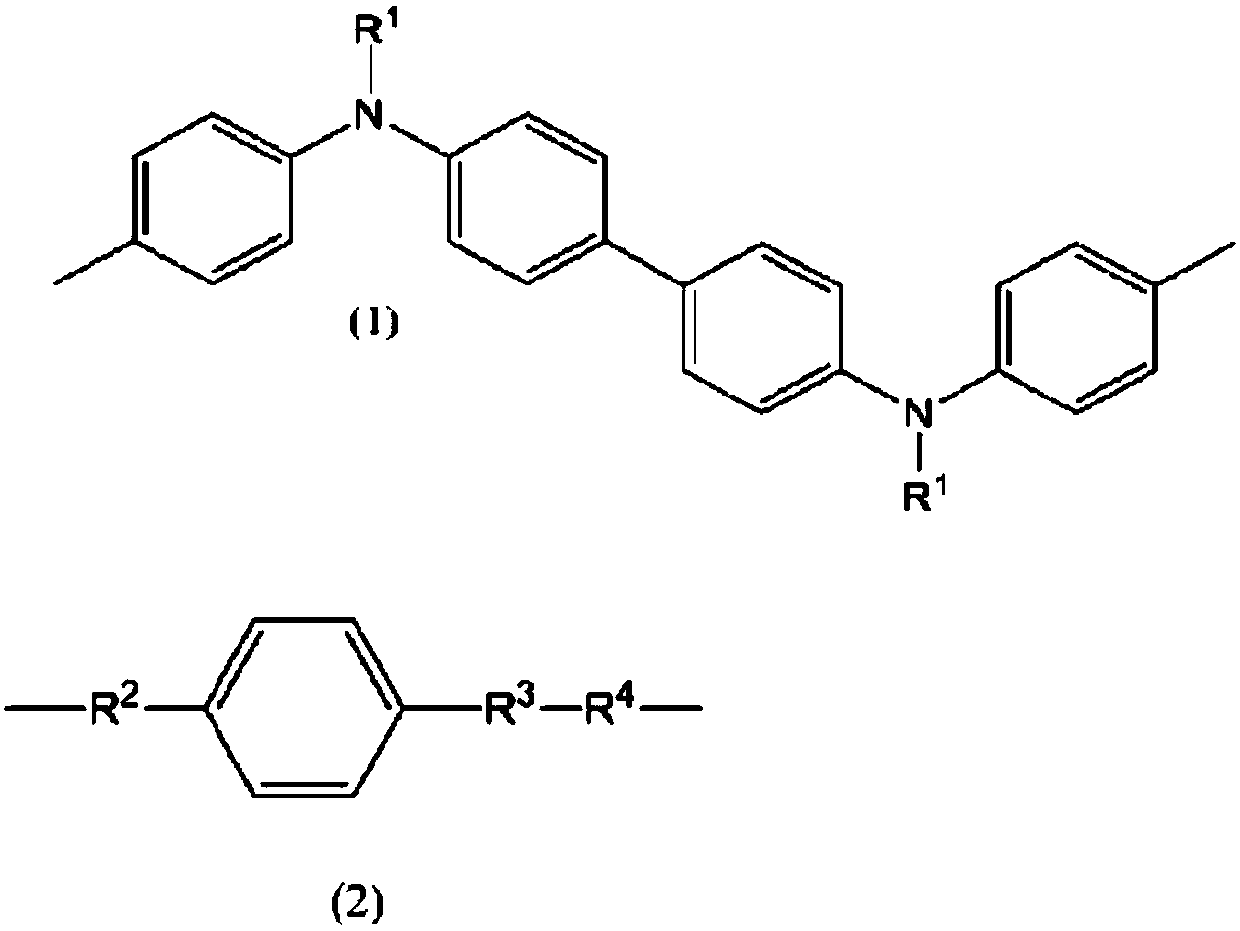

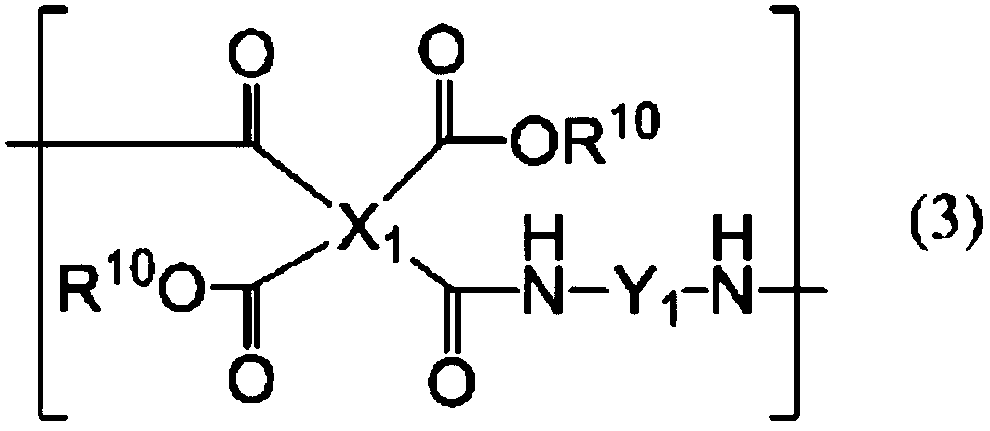

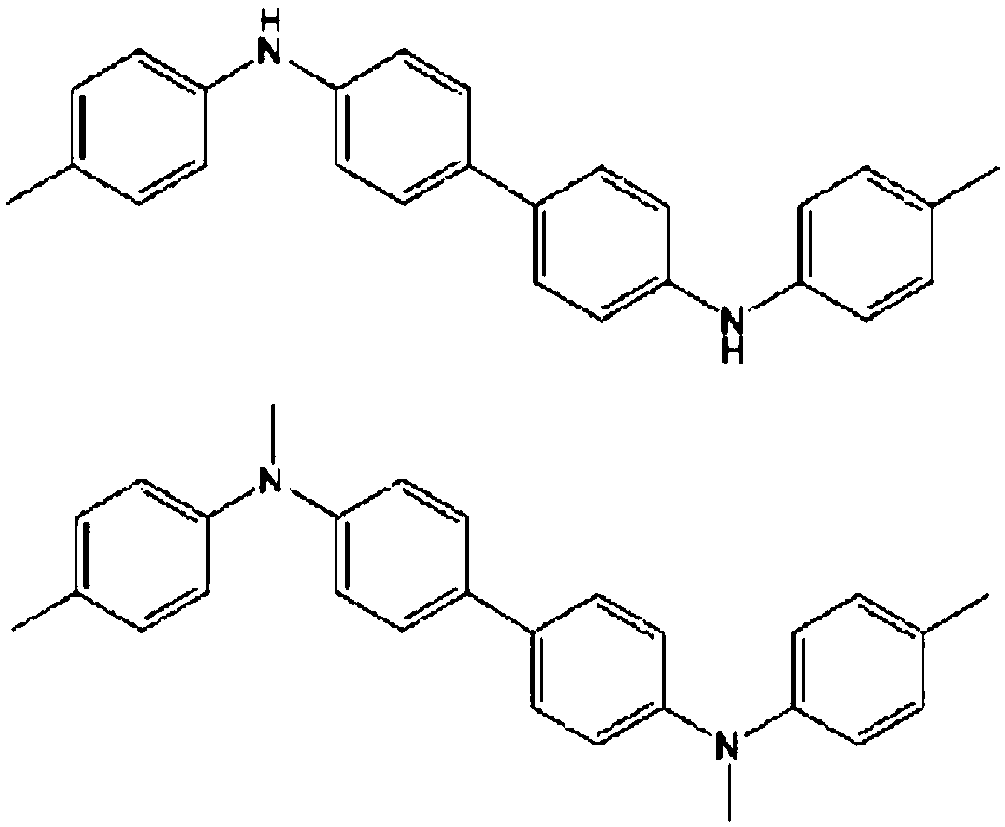

[0166]

[0167]

[0168] The viscosity of the polymer solution was measured using an E-type viscometer TVE-22H (manufactured by Toki Sangyo Co., Ltd.), with a sample volume of 1.1 mL, a cone rotor TE-1 (1°34', R24), and a temperature of 25°C.

[0169]

[0170] The imidization rate of polyimide was measured as follows. 30 mg of polyimide powder was added to NMR (nuclear magnetic resonance) sample tube (NMR standard sampling tube, φ 5 (manufactured by Kusano Science Co., Ltd.)), and deuterated dimethyl sulfoxide (DMSO-d6, 0.05 mass % TMS (four Methylsilane) mixture) (0.53ml) was dissolved completely by applying ultrasonic waves. Proton NMR ...

Synthetic example 1

[0174] Measure DA-1 54.7g (224mmol) and DA-2 53.4g (95.9mmol) in a 1L four-necked flask equipped with a stirring device and a nitrogen gas inlet tube, add 613g of NMP, and stir while feeding nitrogen gas. dissolve. While stirring this diamine solution under water cooling, 89.5 g (298 mmol) of CA-1 was added, and 175 g of NMP was further added, and stirred at 23° C. for 12 hours under a nitrogen atmosphere to obtain a polyamic acid (viscosity: 890 mPa·s) The solution.

[0175] 900 g of this polyamic acid solution was fractionated into a 3 L Erlenmeyer flask equipped with a stirrer, 1350 g of NMP, 74.3 g of acetic anhydride, and 34.6 g of pyridine were added, stirred at room temperature for 30 minutes, and then reacted at 40° C. for 2 hours. This reaction solution was poured into 8300 g of methanol, and the obtained precipitate was filtered off. After washing this deposit with methanol, it dried under reduced pressure at a temperature of 60 degreeC, and obtained the powder of ...

Synthetic example 2

[0178] Measure 86.0 g (352 mmol) of DA-1, 53.4 g (95.9 mmol) of DA-2 and 76.5 g (191 mmol) of DA-3 in a 1 L four-necked flask with a stirring device and a nitrogen inlet tube, 1580 g of NMP was added, stirred and dissolved while sending nitrogen gas. While stirring this diamine solution under water cooling, CA-2 93.2 g (416 mmol) was added, and NMP168g was added further, and it stirred at 40 degreeC in nitrogen atmosphere for 3 hours. Furthermore, CA-3 28.2g (143 mmol) was added, and NMP160g was added further, and it stirred at 23 degreeC for 4 hours under nitrogen atmosphere, and obtained the solution (viscosity: 200mPa*s) of a polyamic acid.

[0179] 800 g of this polyamic acid solution was fractionated into a 3 L Erlenmeyer flask equipped with a stirring bar, 700 g of NMP, 69.7 g of acetic anhydride, and 18.0 g of pyridine were added, stirred at room temperature for 30 minutes, and reacted at 55° C. for 3 hours. This reaction solution was poured into 5600 g of methanol, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com