An apparatus using multiple beams of charged particles

A technology of charged particle beams and equipment, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as pattern defects, connection failures or separation failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

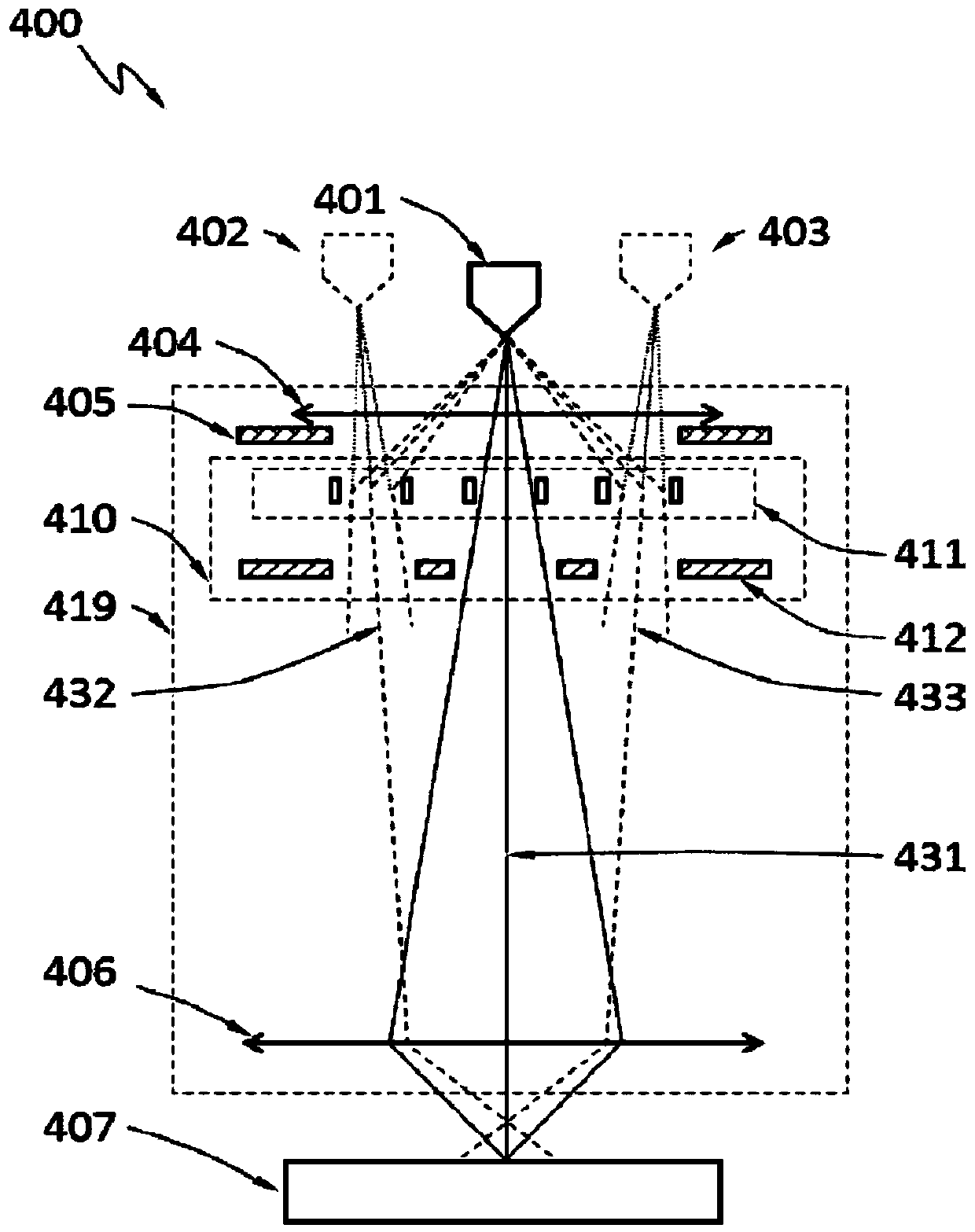

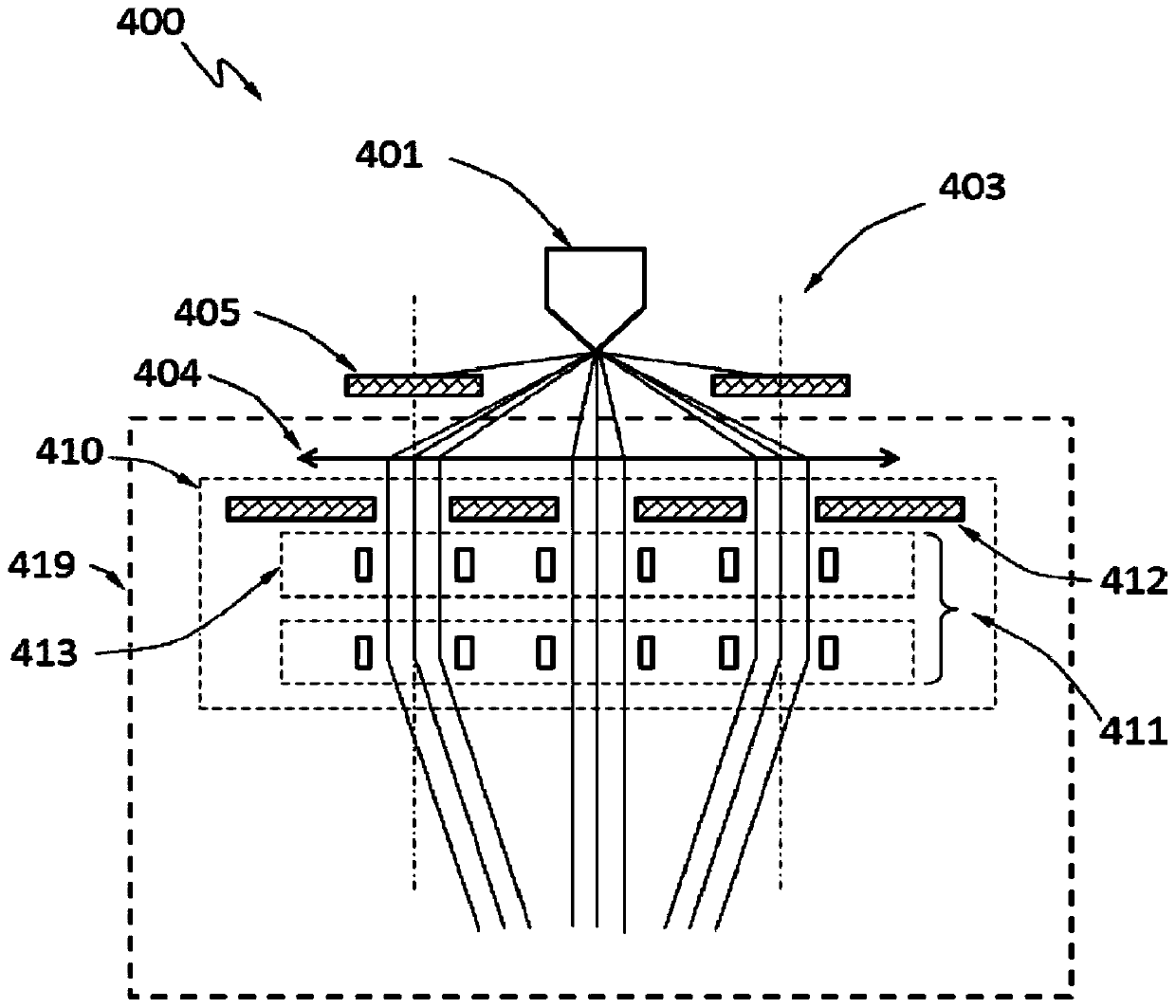

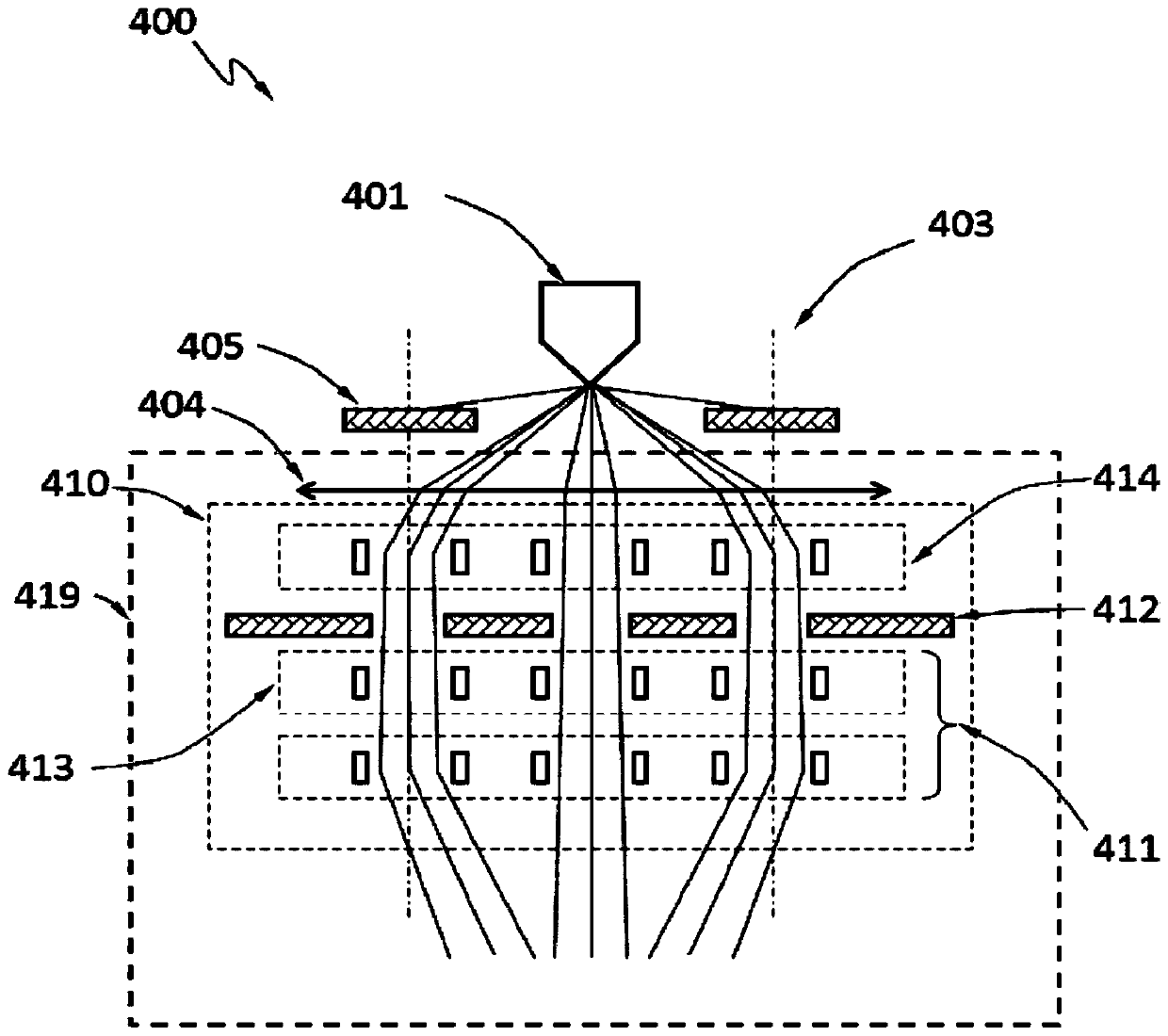

[0056] Various techniques exist for inspecting samples (eg, substrates and patterned devices). One inspection technique is optical inspection, where a beam of light is directed to a substrate or patterning device, and a signal is recorded representing the interaction of the beam with the sample (eg, scattering, reflection, diffraction). Another inspection technique is charged particle beam inspection, in which a beam of charged particles (eg, electrons) is directed to a sample and signals representing interactions of the charged particles with the sample (eg, secondary and backscattered emissions) are recorded.

[0057] Charged particle beam inspection can have higher resolution than optical inspection because the charged particles used in the former have a shorter wavelength than the light used in the latter. Charged particle beam inspection is becoming more widely used as the dimensions of patterns on substrates and patterned devices become smaller as device fabrication proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com