Polypropylene composite material with high vertical thermal conductivity and excellent mechanical properties and preparation method thereof

A composite material and polypropylene technology, applied in the field of polypropylene composite materials and its preparation, can solve the problems of reducing the isotropy of material thermal conductivity, achieve low production costs, improve mechanical properties, and increase thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step (1): vacuum-dry polypropylene, flake graphite and spherical graphite at 80°C for 24 hours;

[0040] Step (2): Add 30g of polypropylene, 18.75g of flake graphite and 1.25g of spherical graphite into the internal mixer for melting and mixing at 190°C. During premixing, the rotor speed of the internal mixer is 20rpm, and melt and knead 2min, then the rotor speed was raised to 50rpm, and melted and kneaded for 5min to obtain a blend;

[0041] Step (3) The obtained blend is subjected to melt compression at a pressure of 20 MPa and a temperature of 220° C. for 7 minutes; at a pressure of 20 MPa and at room temperature for 2 minutes to prepare a sheet with a thickness of 500 μm.

[0042] The test results of the samples are shown in Table 1

Embodiment 2

[0044] Step (1): vacuum-dry polypropylene, flake graphite and spherical graphite at 80°C for 24 hours;

[0045] Step (2): Add 30g of polypropylene, 17.5g of flake graphite and 2.5g of spherical graphite into the internal mixer for melting and kneading at 190°C. During premixing, the rotor speed of the internal mixer is 20rpm, and melt and knead 2min, then the rotor speed was raised to 50rpm, and melted and kneaded for 5min to obtain a blend;

[0046] Step (3) The obtained blend is subjected to melt compression at a pressure of 20 MPa and a temperature of 220° C. for 7 minutes; at a pressure of 20 MPa and at room temperature for 2 minutes to prepare a sheet with a thickness of 500 μm.

[0047] The test results of the samples are shown in Table 1

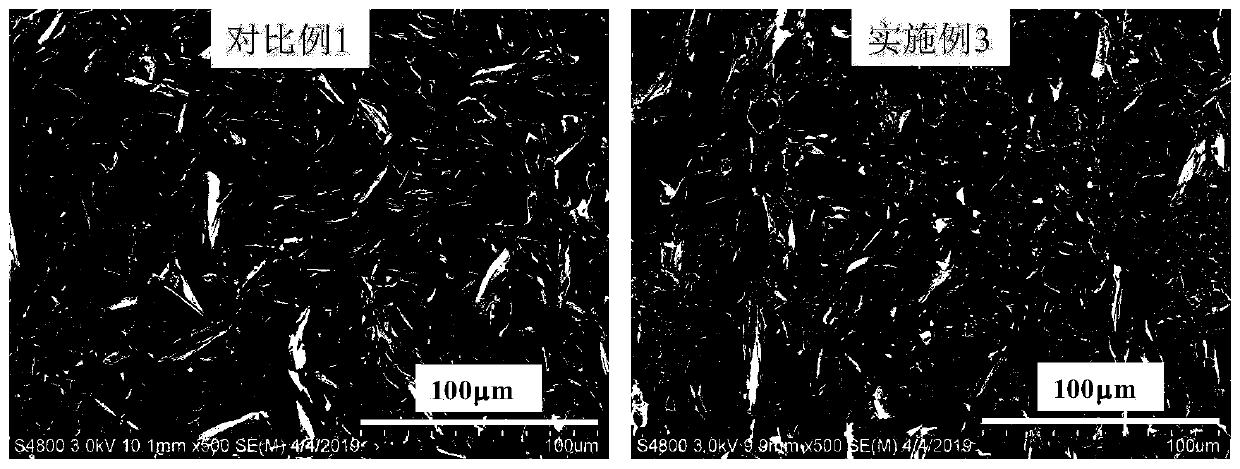

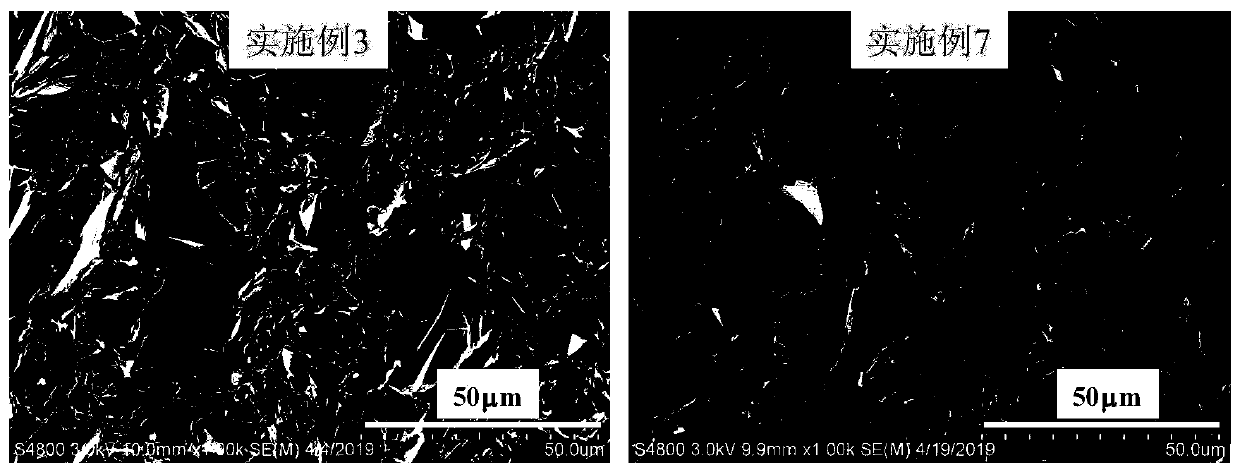

Embodiment 3

[0049] Step (1): vacuum-dry polypropylene, flake graphite and spherical graphite at 80°C for 24 hours;

[0050] Step (2): Add 30g of polypropylene, 15g of flake graphite and 5g of spherical graphite into the internal mixer for melting and mixing at 190°C. During premixing, the rotor speed of the internal mixer is 20rpm, and melt and knead for 2min. Then the rotor speed was increased to 50rpm, melted and kneaded for 5min to obtain the blend;

[0051] Step (3) The obtained blend is subjected to melt compression at a pressure of 20 MPa and a temperature of 220° C. for 7 minutes; at a pressure of 20 MPa and at room temperature for 2 minutes to prepare a sheet with a thickness of 500 μm.

[0052] The test results of the samples are shown in Table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com