Drag reducer, and preparation method and application thereof

A technology of drag reducing agent and coating agent, applied in chemical instruments and methods, mechanical equipment, other chemical processes, etc., can solve problems such as adverse effects, clumping of drag reducing polymer particles, unfavorable application, etc., to reduce settling and sticking. junction, improve dispersion performance, and achieve the effect of drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0045] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

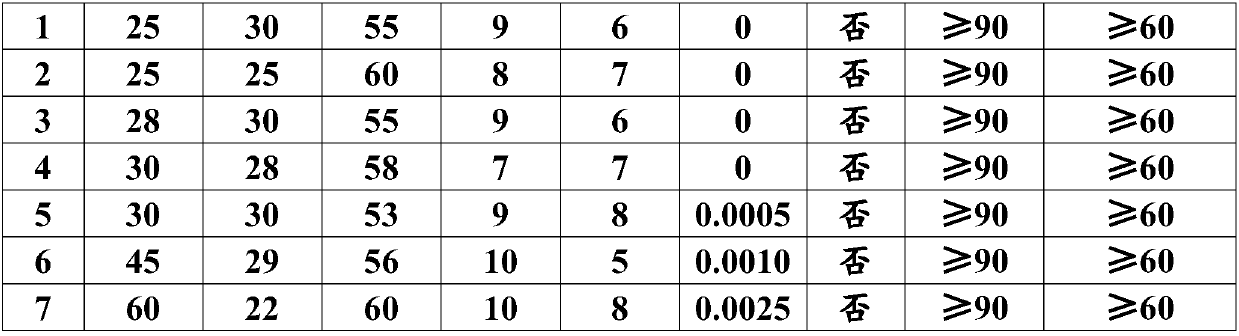

[0046] The performance parameter of the crude oil selected in the present embodiment is as follows:

[0047] crude oil name Viscosity, 50℃, mm 2 / s

[0048] Judging from the oil species tested in this test, sulfur-containing oils have ...

Embodiment 1

[0050] Take the following components by the following parts by mass: (a) α-olefin polymer; 25 parts by mass; (b) carrier component; 100 parts by mass; wherein, (1) oleic acid triglyceride; 30 parts by mass (2) linoleic acid triglyceride; 55 mass parts; (3) palmitic acid triglyceride; 9 mass parts; (4) linoleic acid triglyceride; 6 mass parts;

[0051] Among them, the α-olefin polymer is purchased from Innospec Limited, and its intrinsic viscosity (IV) is 27-29 dl / g. The remaining components can also be obtained from conventional commercial channels in the art.

[0052] The above-mentioned α-olefin polymer is frozen by liquid nitrogen for low-temperature grinding to obtain powder particles with an average particle size of 80-100 mesh. Place the powder particles in the room air and return to ambient temperature for use.

[0053] The above mixture was stirred at high speed with compressed air to prepare drag reducer 1.

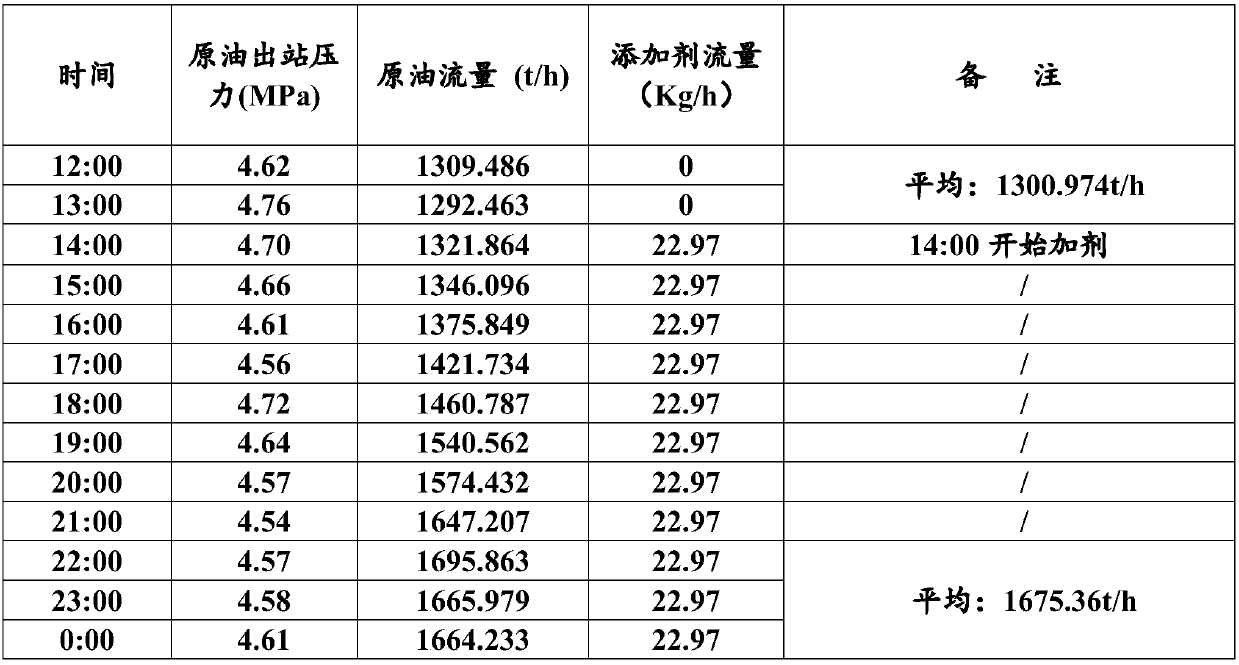

[0054] Carry out performance test to described drag redu...

Embodiment 2-7

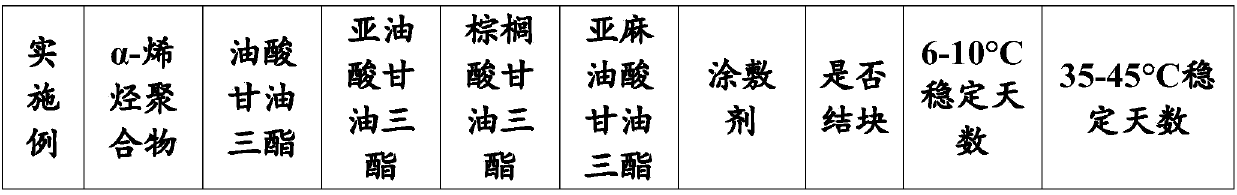

[0061] The preparation method of drag reducer 2-7 is the same as that of Example 1, and the differences are listed in Table 1.

[0062] Table 1 is the component content and stability data of the drag reducer described in Examples 1-7

[0063]

[0064]

[0065] The drag reducers prepared in the above-mentioned Examples 1-7 are all applicable to crude oil, and an additional coating agent has been added in the examples of Examples 5-7, which has a good effect on the engine during the use of oil products. The drag reducing agent of embodiment 5-7 is also particularly suitable for the drag reducing effect of refined oil. Those skilled in the art can understand that if a special content of coating agent is added to the drag reducer of Examples 1-5, it can also be applied to the drag reduction of finished oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com