Novel multi-strain composite starter for flour products and application thereof

A multi-strain, composite surface technology, applied in the direction of application, bacteria, fungi, etc., can solve the problems of high susceptibility to microbial contamination, destruction of nutrients, and difficulty in industrial production, achieving short fermentation time, wide application range, and convenient The effect of storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

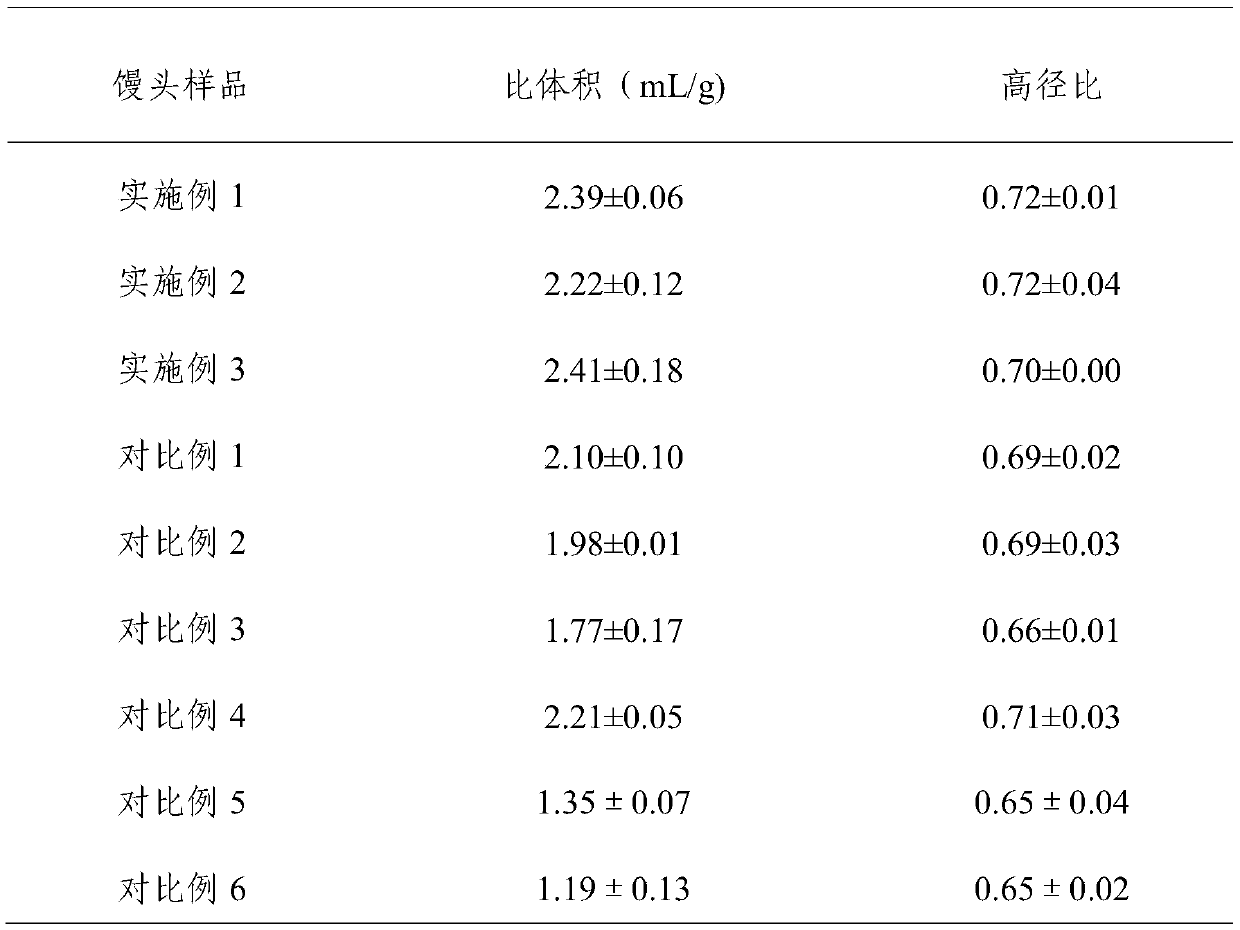

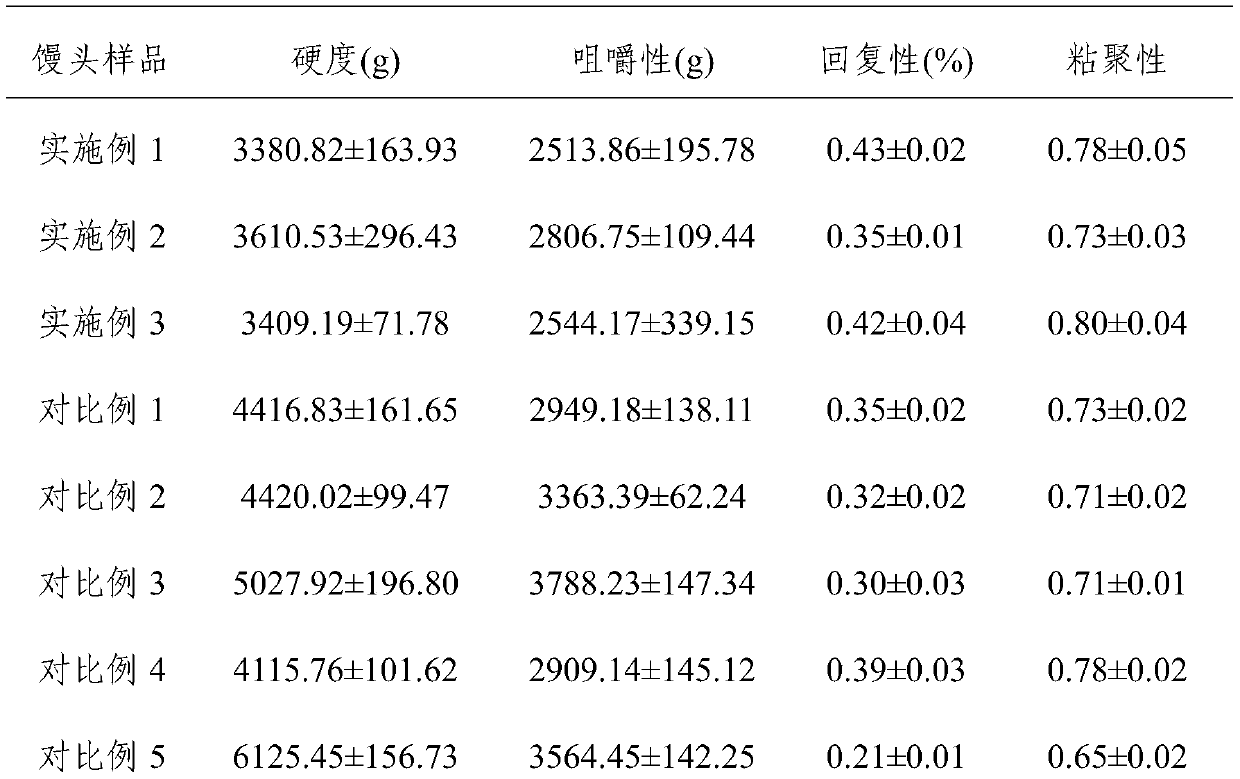

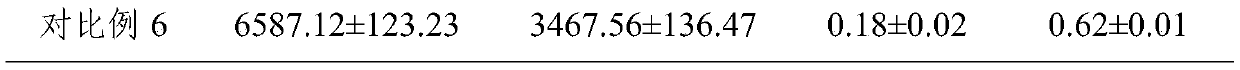

Embodiment 1

[0037] This embodiment provides a novel multi-species compound noodle product starter, which is composed of freeze-dried Lactobacillus plantarum, freeze-dried Lactobacillus bulgaricus, freeze-dried Streptococcus thermophilus, Saccharomyces cerevisiae powder, and abnormal Wickham yeast powder Mixed according to the weight ratio of 2:0.5:0.5:8:1;

[0038] Wherein, the number of live bacteria of the freeze-dried Lactobacillus plantarum is not less than 1×10 10 cfu / g, the number of live bacteria of the freeze-dried Lactobacillus bulgaricus is not less than 1×10 10 cfu / g, the number of live bacteria of the freeze-dried Streptococcus thermophilus is not less than 1×10 10 cfu / g, the number of live bacteria of the said Saccharomyces cerevisiae powder is not less than 2×10 10 cfu / g, the number of live bacteria of the abnormal Wickham yeast powder is not less than 1×10 10 cfu / g;

[0039] The various bacterial species used come from the commercially available single viable bacterial ...

Embodiment 2

[0046] This embodiment provides a novel multi-strain composite noodle product starter, the only difference from Example 1 is that the novel multi-strain composite noodle product starter consists of freeze-dried Lactobacillus plantarum and freeze-dried Bulgarian milk Bacillus, freeze-dried Streptococcus thermophilus, Saccharomyces cerevisiae powder, and abnormal Wickham's yeast powder are mixed according to the weight ratio of 1:1:1:6:3.

[0047] This embodiment also provides steamed buns prepared by using the above-mentioned novel multi-strain composite noodle product starter, and the preparation method of the steamed buns is the same as that in Example 1.

Embodiment 3

[0049] This embodiment provides a novel multi-strain composite noodle starter, and the novel multi-strain composite noodle starter is the same as in Example 1;

[0050]This embodiment also provides steamed buns prepared by using the above-mentioned novel multi-strain composite noodle product starter, the difference from the first embodiment is only that the raw material flour of the steamed buns is wheat flour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com