Integrally movable aluminum alloy formwork system and operation method

An aluminum alloy formwork, integral moving technology, applied in the direction of formwork/formwork/work frame, water conservancy project, artificial island, etc., can solve the problems of difficult movement, high cost, heavy construction weight, etc., to reduce man-hours, reduce disassembly and Assembling and controlling the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

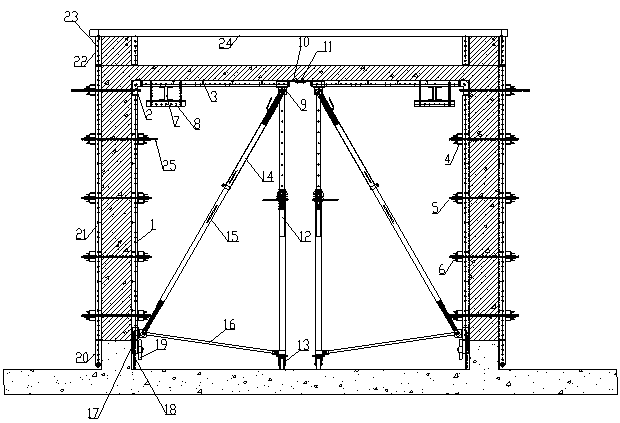

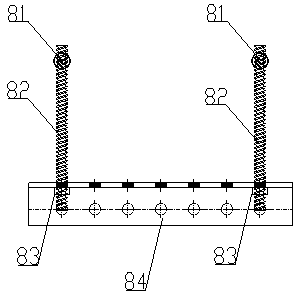

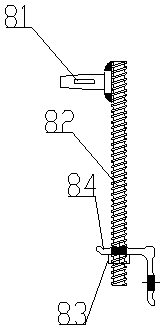

[0077] Such as Figure 1 to Figure 11 As shown, an integrally movable aluminum alloy formwork system includes a formwork system, a support system and a fastening system. The formwork system includes a plurality of aluminum alloy formwork bodies, and the support system includes vertical supports and The oblique support and the fastening system connect multiple aluminum alloy formwork bodies to form a formwork system. The aluminum alloy formwork body includes interior wall formwork and exterior wall formwork, and the interior wall formwork includes wall body formwork and top surface formwork. In the bay, there are two sets of corresponding formwork systems, the two sets of formwork systems are installed independently, and the two sets of top formwork are connected through the connecting plate 10, and the overall matching forms a bay formwork system; it consists of wall formwork, top formwork and oblique support The formed triangular formwork support structure and the triangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com