Interface protection structure and preparation method thereof and battery having interface protection structure

An interface protection and battery technology, applied in the field of electrochemical energy storage, can solve the problems of inability to block the direct contact between electrolyte and lithium metal, complicated interface or structure nanotechnology, loss of lithium metal and electrolyte, etc., and is conducive to large-scale Promote, improve Coulombic efficiency and cycle life, and improve the effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

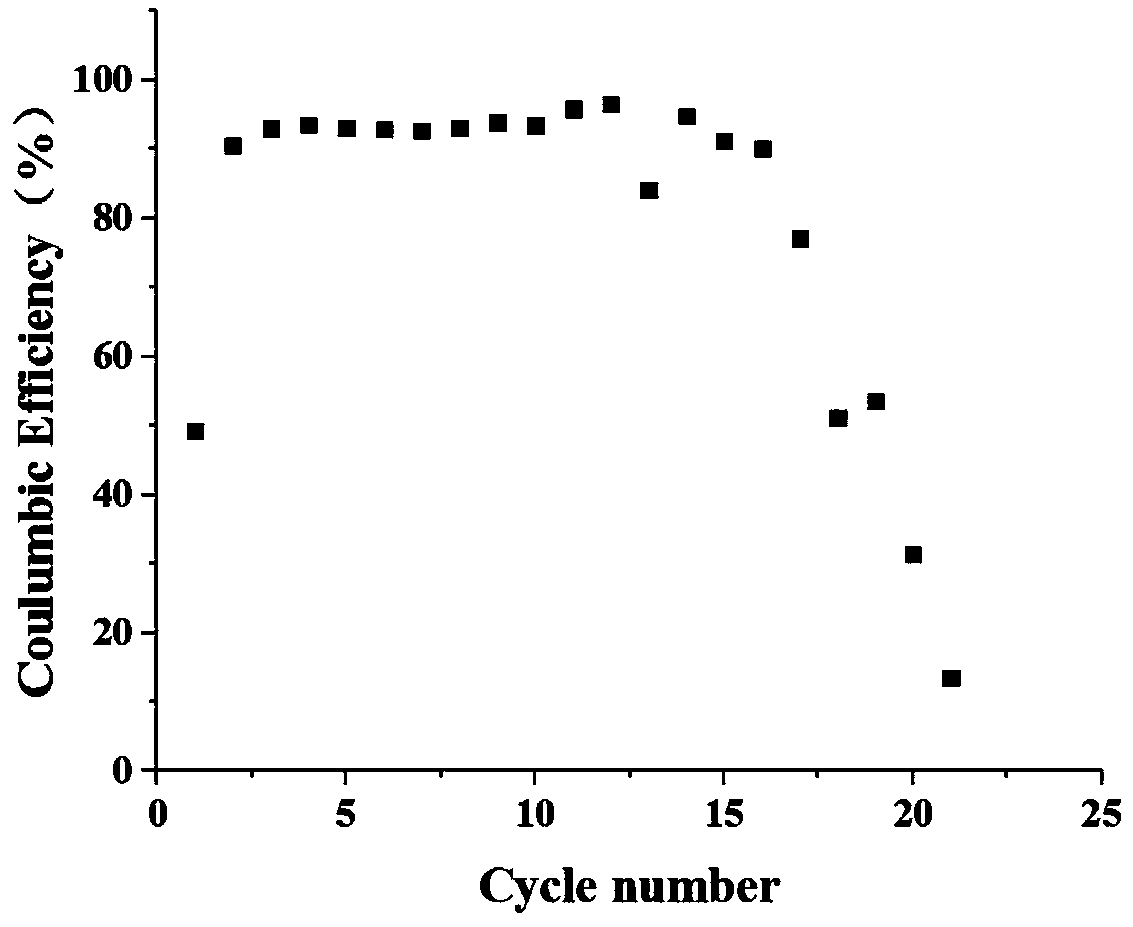

Embodiment 1

[0053] The invention provides an interface protection structure, which is made of a main material, and the main material adopts foamed graphene (FG). The preparation method is as follows:

[0054] Take 30mg of FG powder, put it into a mixture of pure water and ethanol (1:1 volume ratio, about 50ml) for ultrasonic dispersion, and then simply suction filter and peel off to obtain the interface protection structure. The Buchner funnel is used for suction filtration on qualitative filter paper, and then the obtained interface protection structure can be cut to form the required specifications.

[0055] The interface protection structure obtained in this example was assembled as a half-cell according to the above-mentioned button-type lithium metal secondary half-cell assembly method.

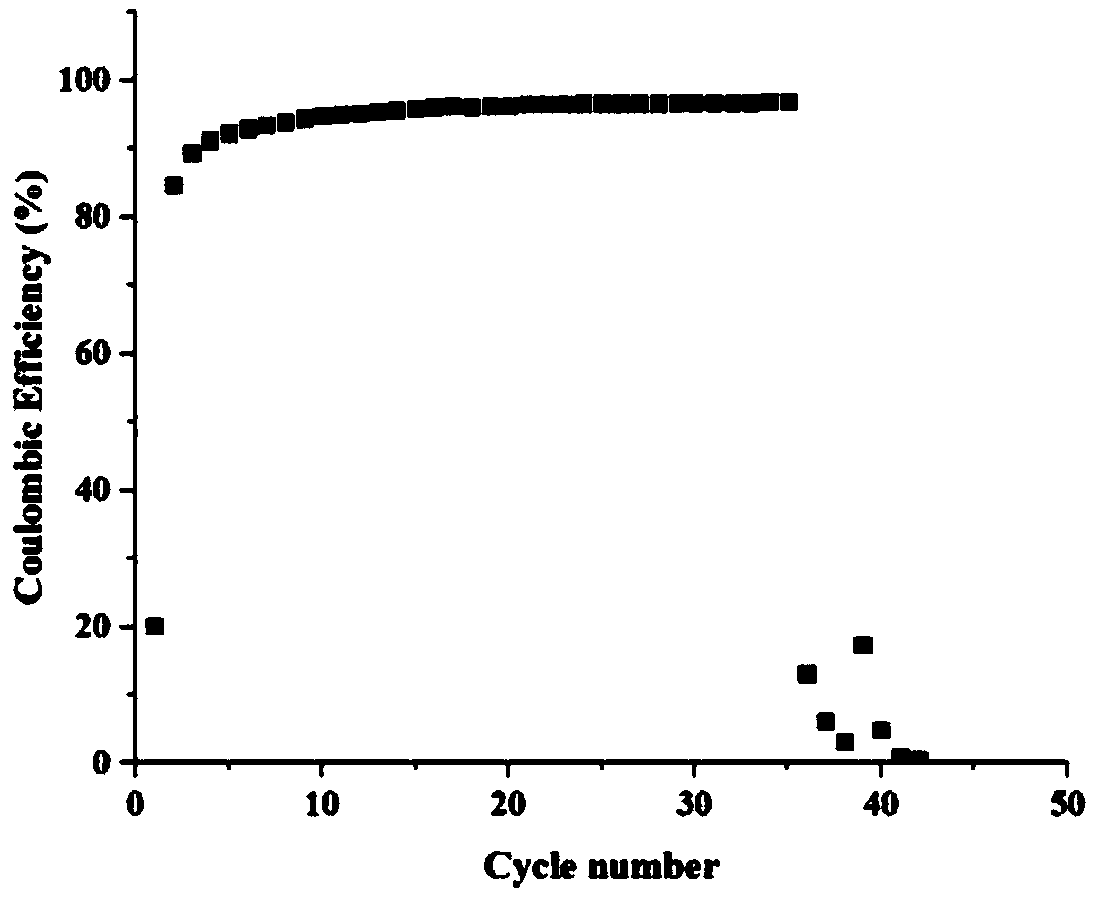

Embodiment 2

[0057] The invention provides an interface protection structure, which is made of a host material, which is a powder mixed with foamed graphene (FG) and carbon nanotubes (CNT) at a mass ratio of 9:1. The preparation method is as follows:

[0058] Take 30mg of FG+CNT powder, put it into a mixture of pure water and ethanol (1:1 volume ratio, about 50ml) for ultrasonic dispersion, and then simply suction filter and peel off to obtain the interface protection structure. 70mm qualitative filter paper is used for suction filtration with a Buchner funnel, and then the obtained interface protection structure can be cut to form the required specifications.

[0059] The interface protection structure obtained in this example was assembled as a half-cell according to the above-mentioned button-type lithium metal secondary half-cell assembly method.

Embodiment 3

[0061] The difference between Example 3 and Example 2 is that the mass ratio of the two in FG+CNT powder is changed to 8:2. Others are the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com