A kind of fine sugar granule and its preparation method, equipment and application

一种细颗粒、用途的技术,应用在糖细颗粒及其制备领域,能够解决糖粉流动性差、无法顺畅下料、混匀差等问题,达到药物稳定性有利、节约生产成本、流动性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

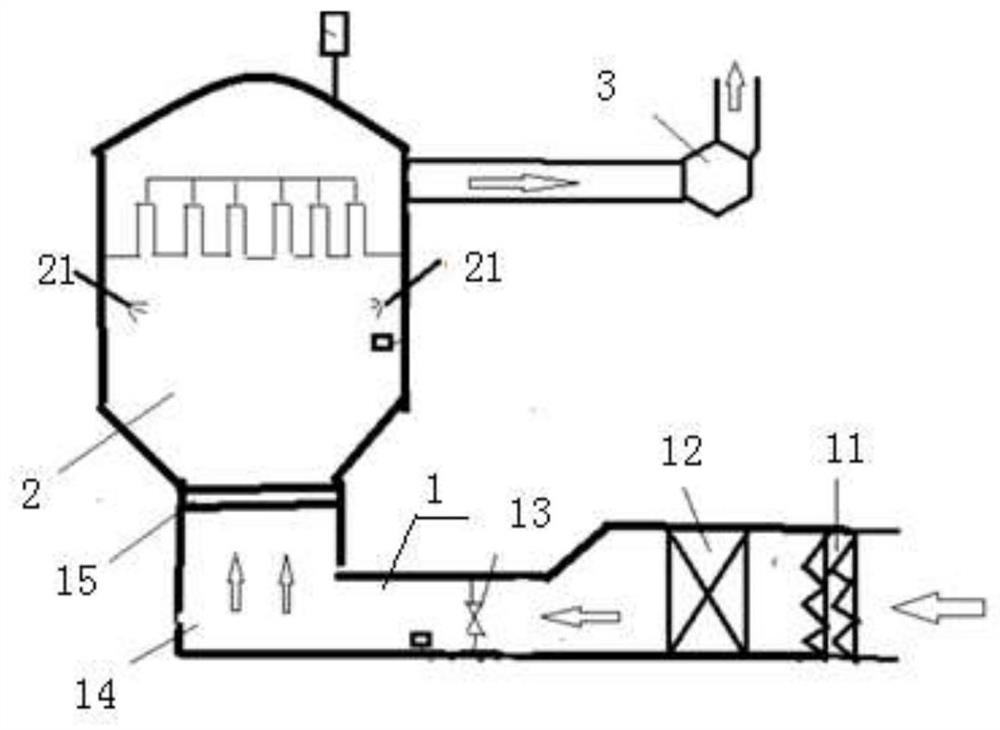

Method used

Image

Examples

Embodiment 1

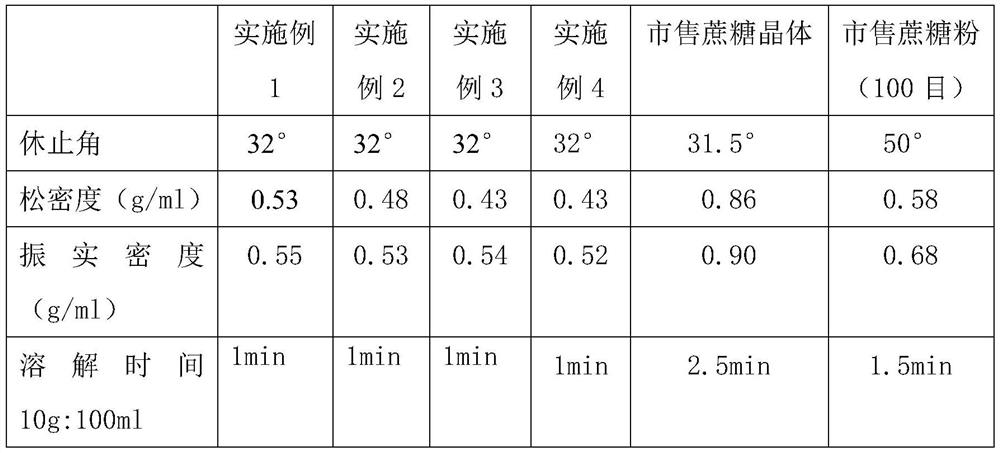

[0043] The preparation of embodiment 1 sugar fine particle

[0044] Mix and pulverize 99.9:0.1 sucrose and glucose syrup powder to obtain powdered sugar with a particle size of 100 mesh. The obtained powdered sugar is blown up with hot air in the fluidized bed, and water is sprayed at the same time. The volume of the fluidized bed and the material The weight ratio is 10.75L / KG, the pressure of the water jet pump is 3 kg, and the hot air volume is 8000 cubic meters per hour. The prepared sugar fine particles have a particle size of 60 mesh, an apparent density of 0.53 g / ml, and an angle of repose of 32°.

Embodiment 2

[0045] The preparation of embodiment 2 sugar fine particles

[0046] The 99.5:0.5 sucrose and glucose syrup powder are mixed and pulverized to obtain powdered sugar with a particle size of 100 mesh. The obtained powdered sugar is blown up with a hot air flow in the fluidized bed, and water is sprayed at the same time. The volume of the fluidized bed and the material The weight ratio is 10.75L / KG, the pressure of the water jet pump is 5 kg, and the hot air volume is 8000 cubic meters per hour. The prepared sugar fine particles have a particle size of 70 mesh, an apparent density of 0.48 g / ml, and an angle of repose of 32°.

Embodiment 3

[0047] The preparation of embodiment 3 sugar fine particles

[0048] The 99.7:0.3 sucrose and glucose syrup powder are mixed and pulverized to obtain powdered sugar with a particle size of 100 mesh. The obtained powdered sugar is blown up with hot air in the fluidized bed, and water is sprayed at the same time. The volume of the fluidized bed and the material The weight ratio is 10.75L / KG, the pressure of the water jet pump is 8 kg, and the hot air volume is 5000 cubic meters per hour. The prepared sugar fine particles have a particle size of 100 mesh, an apparent density of 0.43 g / ml, and an angle of repose of 32°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com